Degradable polyvinyl chloride film and preparation method thereof

A polyvinyl chloride film and polyvinyl chloride resin technology, applied in the field of degradable PVC film and its preparation, can solve the problems affecting the processing characteristics of PVC film, film mechanical and physical properties, low lead content, dispersibility, poor fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The specific implementation manner of the present invention is introduced below through several examples.

[0085] The following implementation and verification were carried out according to the steps of the preparation method of the degradable polyvinyl chloride film described above.

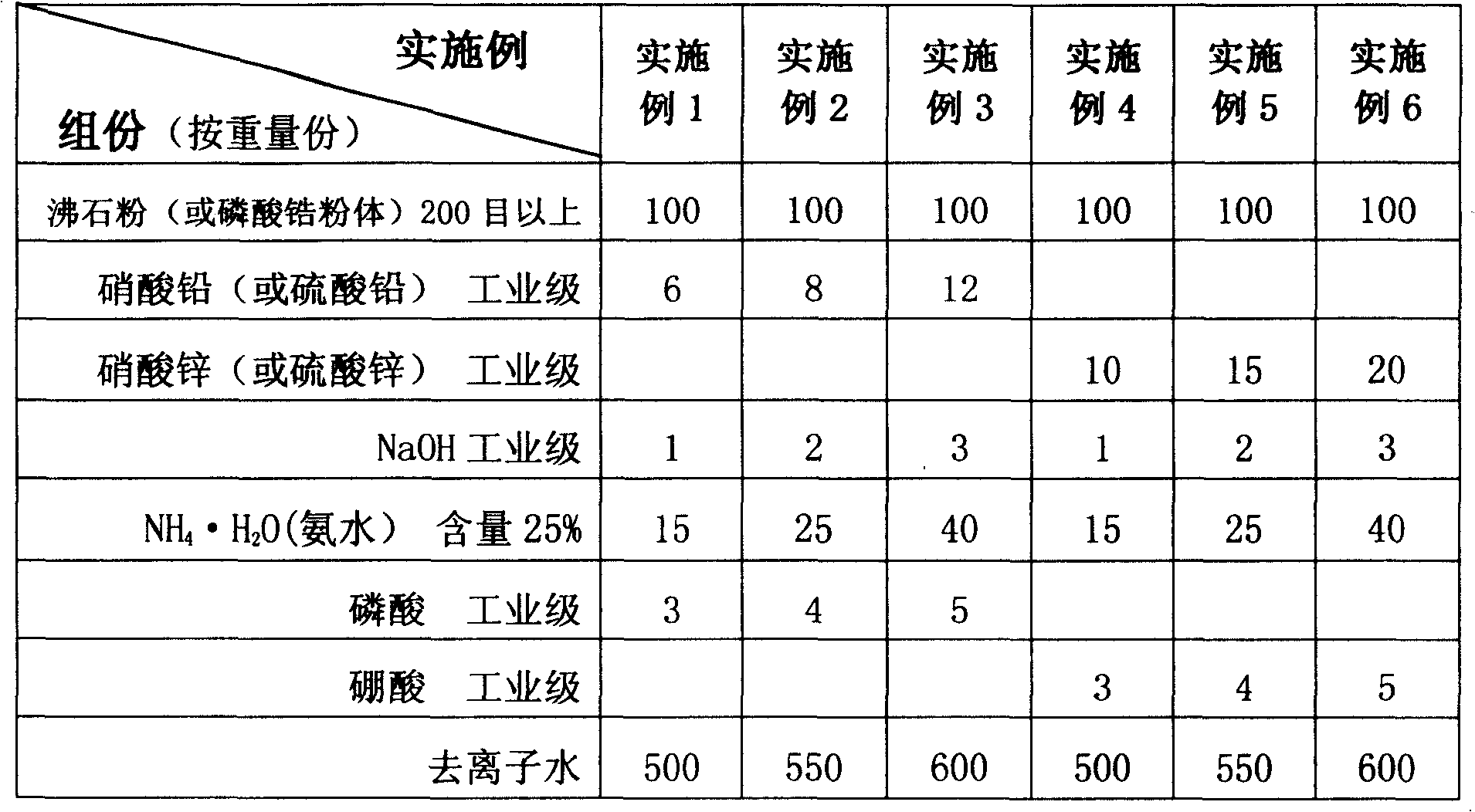

[0086] One, prepare the embodiment of nano-lead or nano-zinc, provide 6 embodiments, its composition sees the following table for details:

[0087]

[0088] In Example 1, weigh 500 kg of deionized water, pour it into a glass-lined reactor with a jacket heating and stirring device and stir at 60-80 rpm, add 1 kg of NaOH, and stir for 15 minutes until dissolved. Add 6 kg of lead nitrate (or lead sulfate), stir for 15 minutes until dissolved, add 15 kg of ammonia water (content 25%), gradually raise the temperature to 50-60°C, stir for 20-30 minutes, then add high-temperature-treated zeolite powder 100 kg of zirconium phosphate powder or zirconium phosphate powder, and heat up to 85 ~ 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com