Method for preparing hydroxyethyl starch

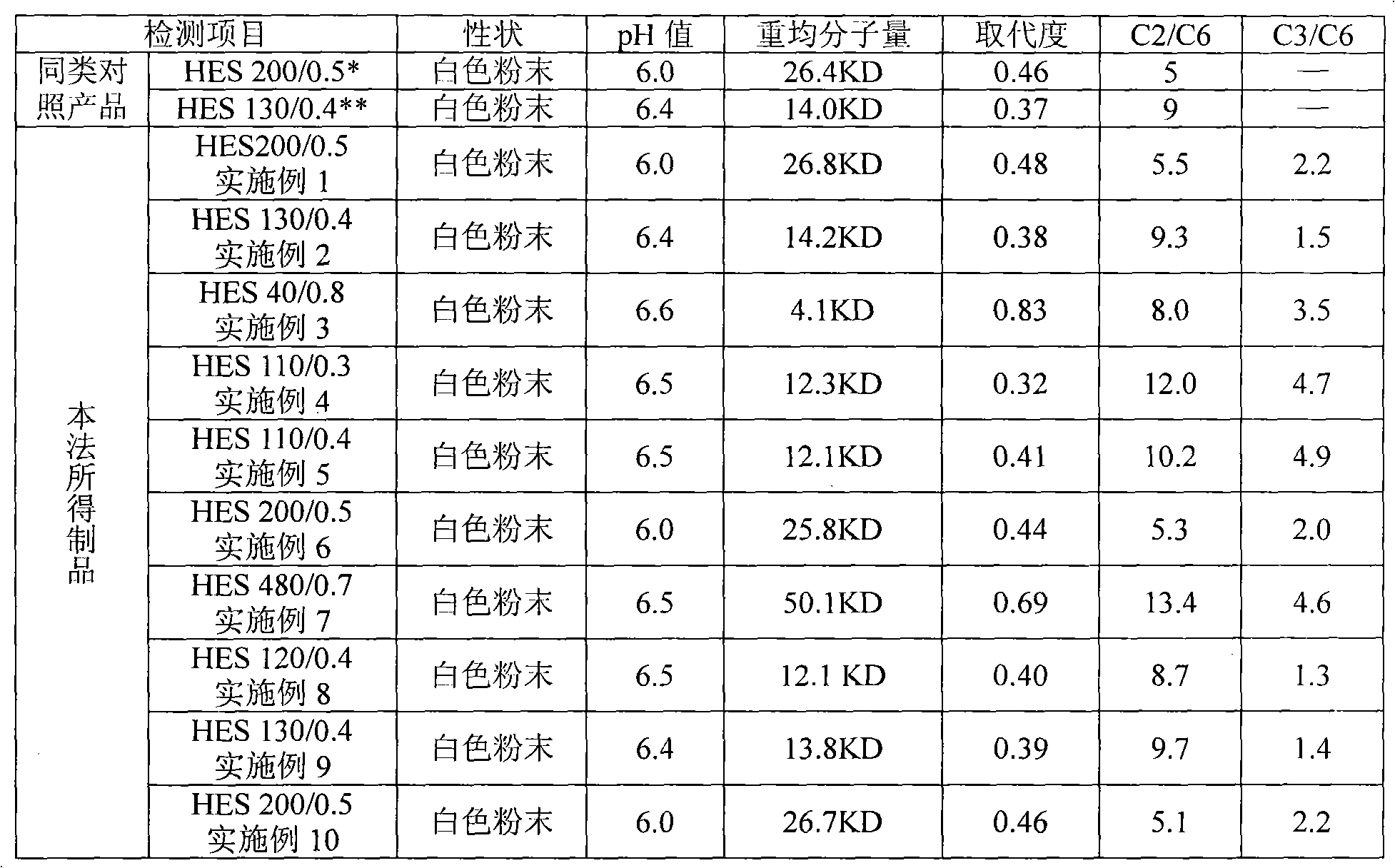

A technology of hydroxyethyl starch and hydroxyethylation, applied in blood diseases, extracellular fluid diseases, drug combinations, etc., can solve the problems of reducing product quality, cumbersome preparation process, difficult control of starch molecular weight, etc., to avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 25 L of aqueous solution containing 95% (v / v) ethanol to the reaction kettle, add 0.25 kg of sodium hydroxide under stirring, add 10 kg of cornstarch (pH>13, the same below) after dissolving, seal the reaction kettle, and feed nitrogen into it Empty the air in the reaction kettle, add ethylene oxide, stir the reaction, add 2mol / L hydrochloric acid to neutralize to pH 6-8 after completion, filter and dry to obtain the hydroxyethylated starch intermediate.

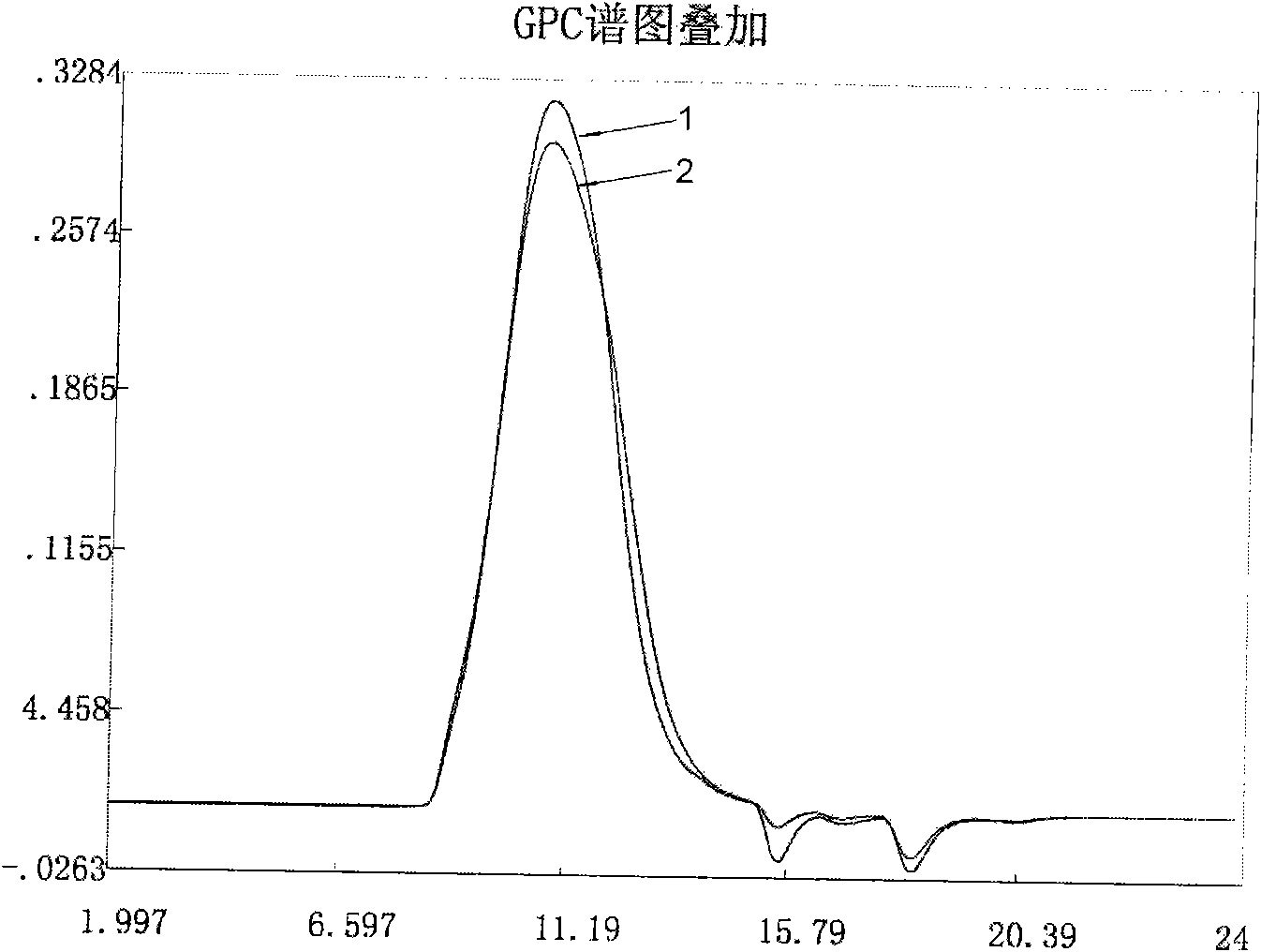

[0024] Add 30L of 6% hydrochloric acid solution (pH ≤ 1, the same below) to the hydrolysis reaction kettle, add the above-mentioned intermediate under stirring, and after timing and stirring for 4 to 4.5 hours, neutralize to pH 6 with 5mol / L sodium hydroxide solution Add 0.05% (w / v) of activated carbon, keep stirring for 15 minutes, pass through a 1 μm titanium rod for decarbonization, then use a 10KD ultrafiltration membrane to ultrafilter and spray dry to obtain (HES 200 / 0.5) product. The comparison of this prod...

Embodiment 2

[0026]Add 50L of isopropanol solution to the reaction kettle, add 2.0kg of sodium hydroxide under stirring, add 10kg of cornstarch after dissolving, seal the reaction kettle, feed nitrogen to evacuate the air in the reaction kettle, after adding chloroethanol, in 30 ℃~35℃, stir the reaction, add 2mol / L hydrochloric acid to neutralize after completion, adjust the pH to 6~8, filter and dry.

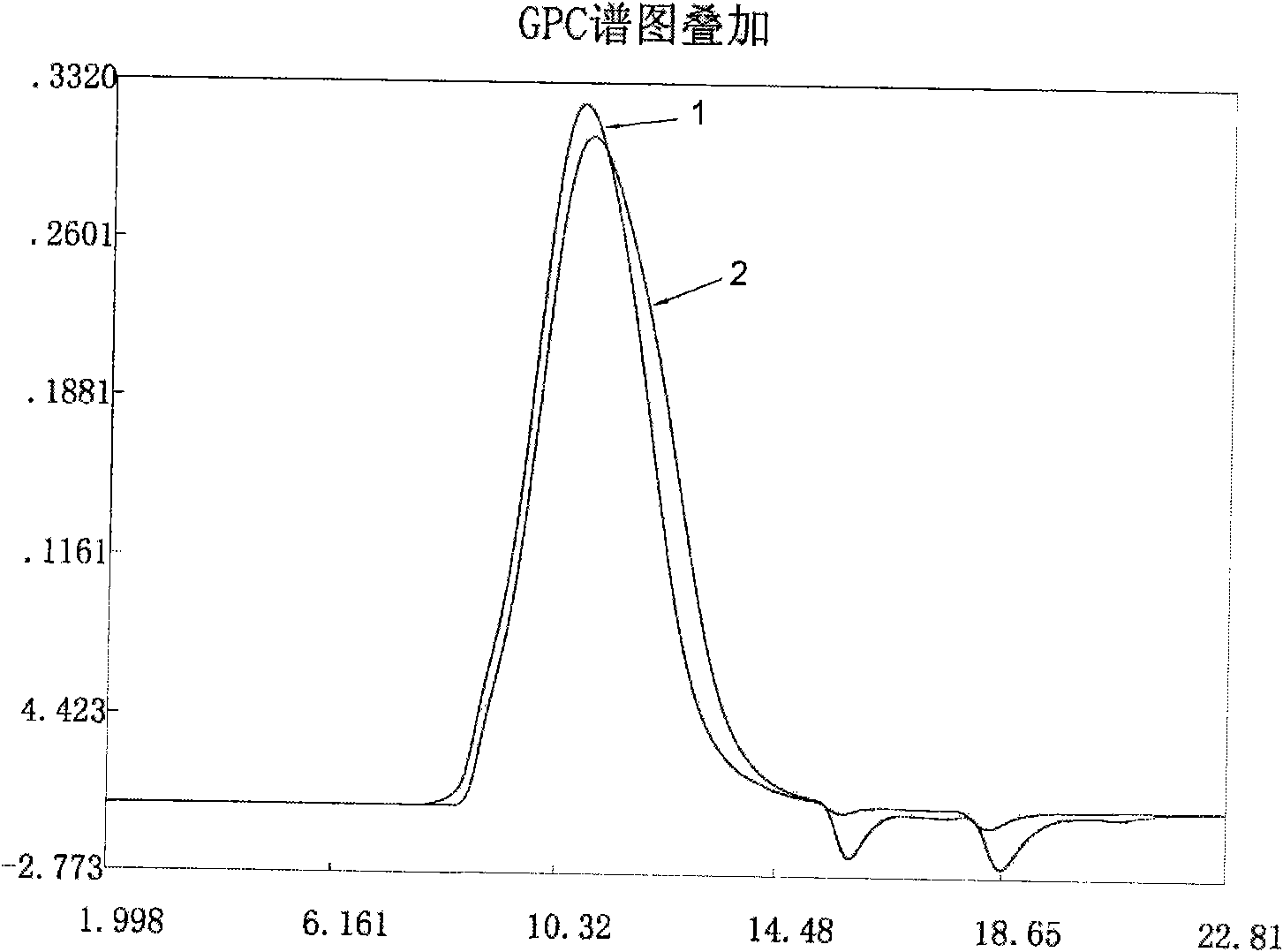

[0027] Add 80L of 5% hydrochloric acid solution to the hydrolysis reaction kettle, heat up to 50°C-55°C, add the above-mentioned intermediate under stirring, and after timing and stirring for 6-6.5 hours, neutralize with 5mol / L sodium hydroxide solution to When the pH is about 6, add 0.3% (w / v) activated carbon, heat and stir for 15 minutes, pass through a 1 μm titanium rod for decarbonization, refine with absolute ethanol, and spray dry to obtain (HES 130 / 0.4) product. The comparison of this product with the same product (batch number C0502013A) of Germany Fresenius Kabi Co., Ltd. in molec...

Embodiment 3

[0029] Add 30L of 90% methanol aqueous solution in the reactor, add 0.5kg of sodium hydroxide under stirring, add cornstarch 10kg after dissolving, seal the reactor, pass into nitrogen to evacuate the air in the reactor, add ethylene oxide, At 20°C-25°C, after the stirring reaction is completed, add 2mol / L hydrochloric acid for neutralization, adjust the pH to 6-8, filter, and dry.

[0030] Add 50L of 10% hydrochloric acid solution to the hydrolysis reaction kettle. After heating up to 55°C-60°C, add the above-mentioned intermediate under stirring. After timing and stirring for 7-7.5 hours, neutralize with 5mol / L sodium hydroxide solution to When the pH is about 6, add 0.1% (w / v) activated carbon, heat and stir for 15 minutes, pass through a 1 μm titanium rod for decarbonization, ultrafilter with a 3KD ultrafiltration membrane, and spray dry to obtain a (HES 40 / 0.8) product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com