Filter assembly

A filter assembly and filter technology, applied in membrane filters, dispersed particle filtration, chemical instruments and methods, etc., can solve problems such as damage and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

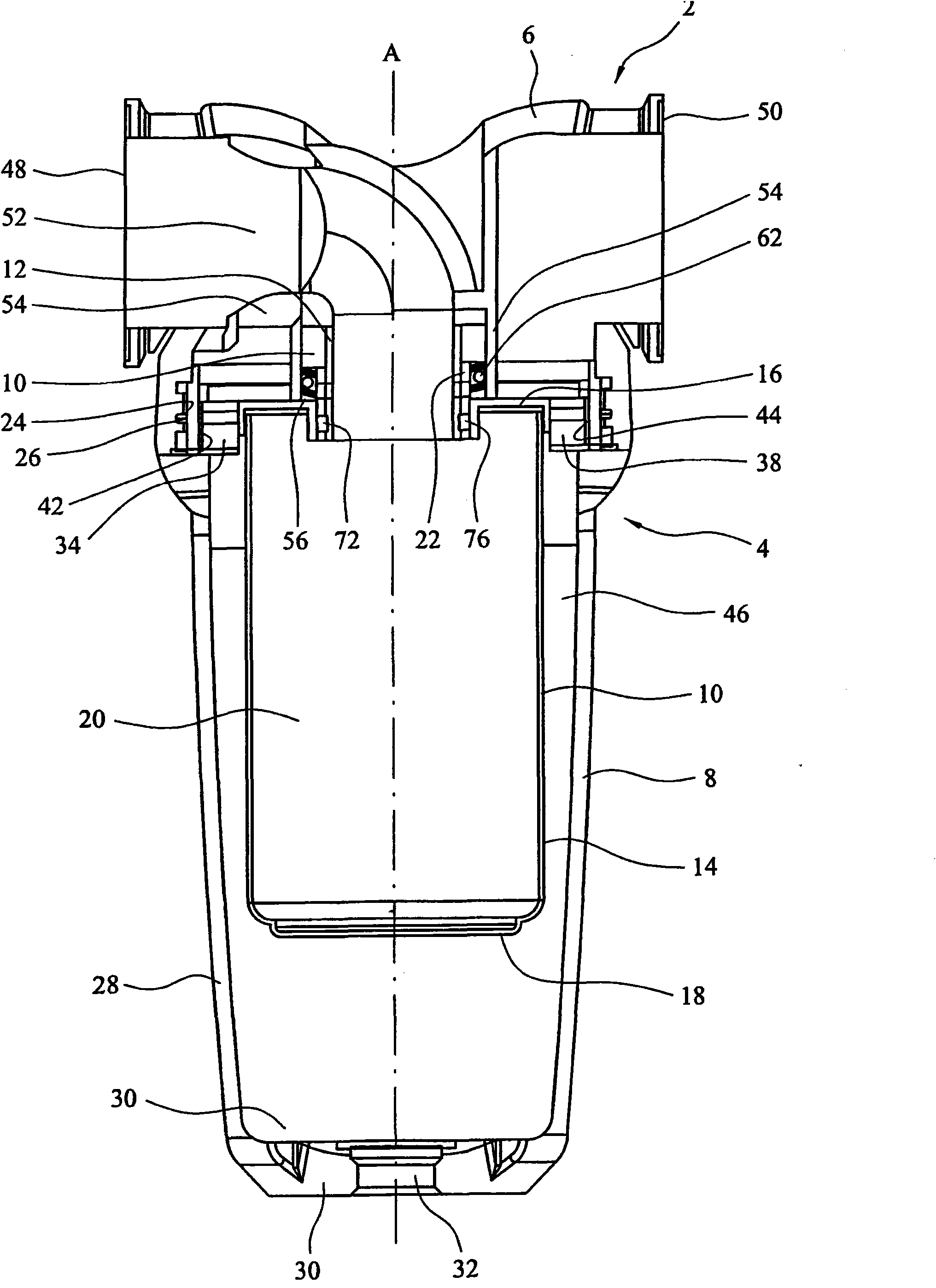

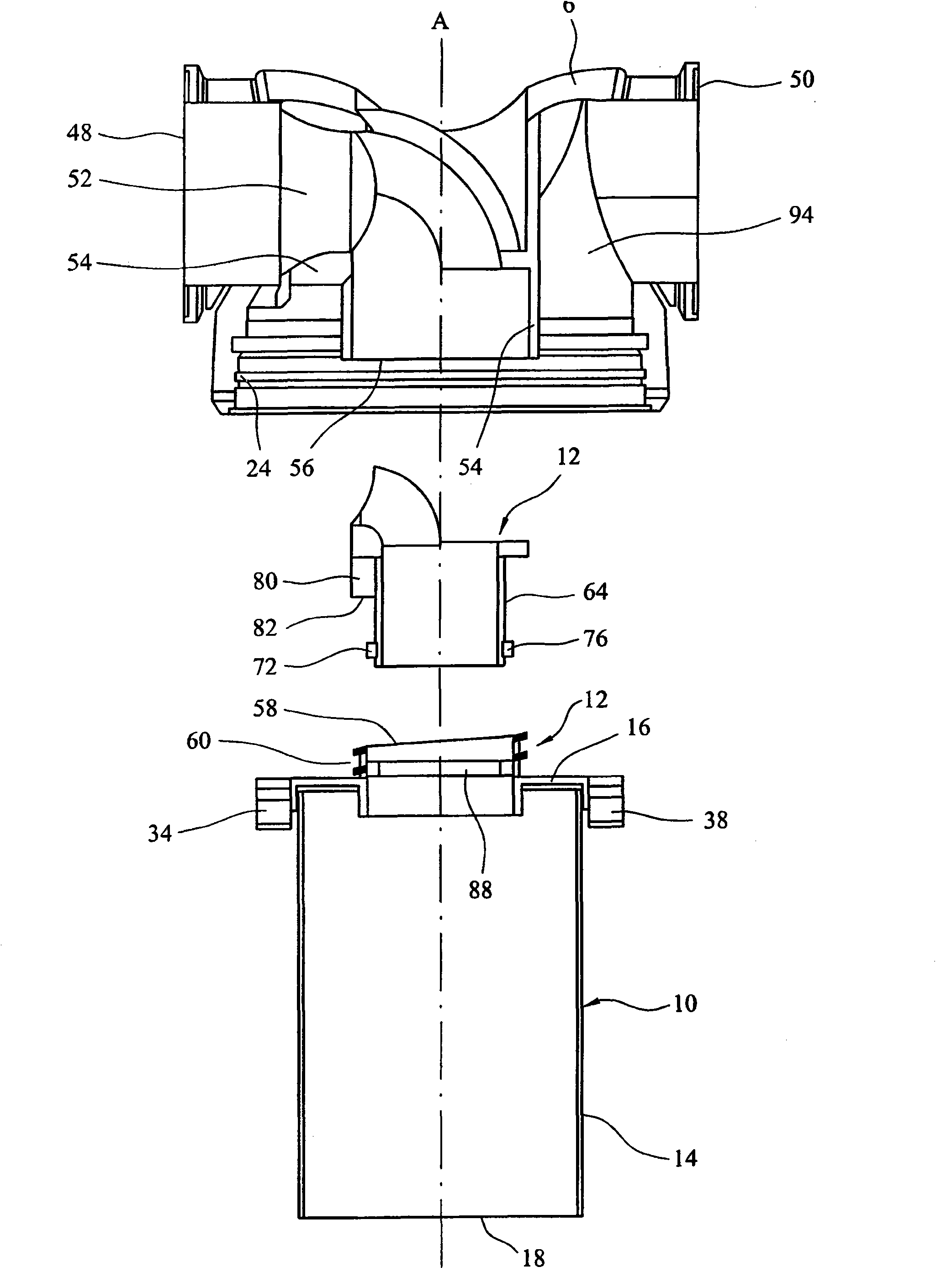

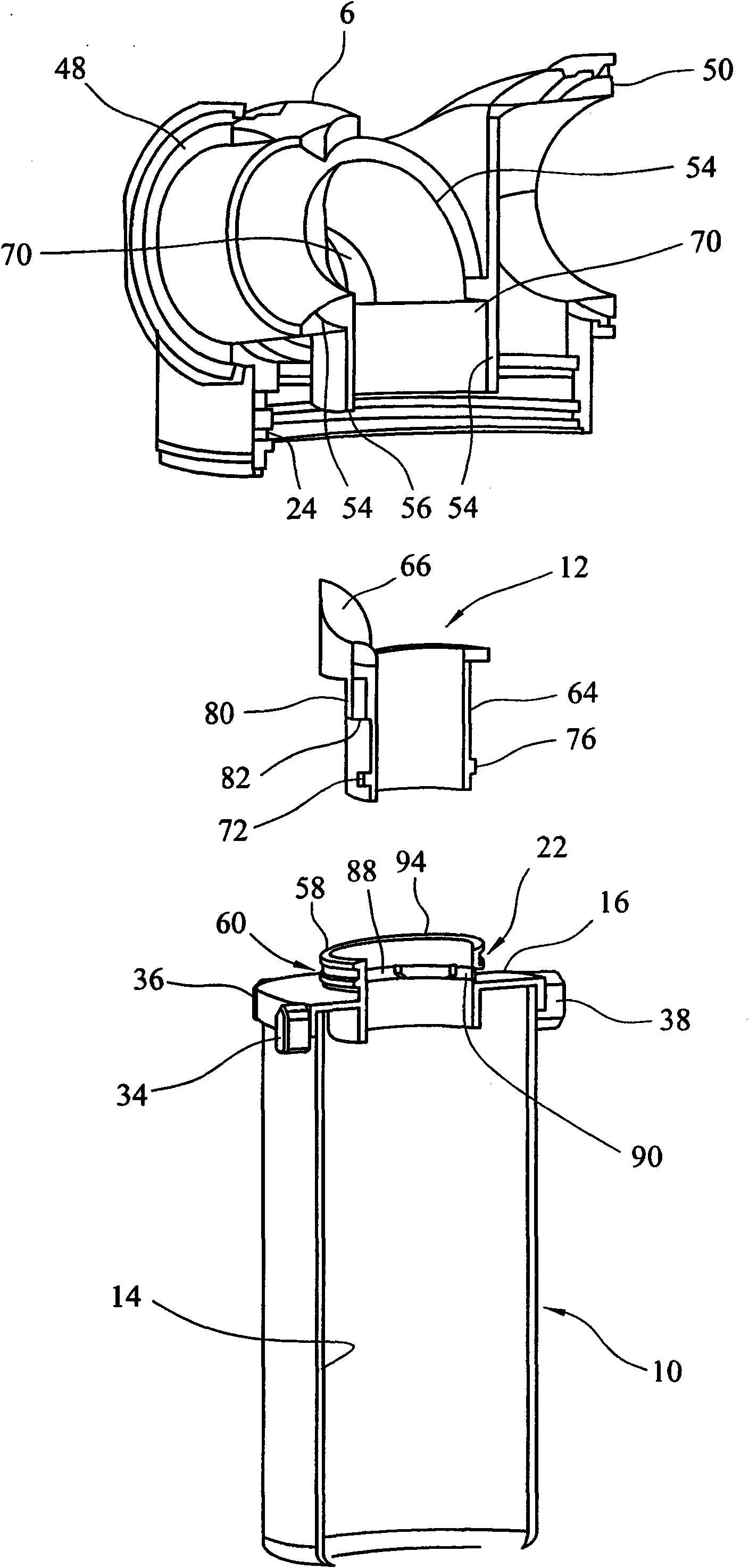

[0056] With reference to the accompanying drawings, figure 1 A filter assembly 2 is shown comprising a housing 4 having a head 6 and a body portion 8 , a filter element 10 and a flow controller 12 . The head 6 and body part 8 have engaging formations in the form of cooperating threads 24, 26 which allow the head 6 and body part 8 to be interconnected and detached by relative rotation about the A-axis. The head 6 has a head axis and the body part 8 has a body axis, each of these axes being coaxial with the A-axis.

[0057] In the depicted embodiment, filter element 10 includes a cylindrical wall portion 14 formed of filter media, and top end caps 16 and bottom end caps 18 . as Figures 2 to 4 As best shown, the wall portion 14 of the filter element 10 defines a cavity 20 within it.

[0058] The top end cap 16 and the bottom end cap 18 are formed from a polymer material. It will be appreciated that suitable polymeric materials include polyolefins (particularly polyethylene a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com