High-temperature resistant dual-layer insulating seamless lapped wire

A double-layer insulation and high-temperature-resistant technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve problems such as loose bonding, poor vacuum air permeability of silicone rubber, and reduced performance of wires, so as to ensure the temperature resistance level and improve The effect of job stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

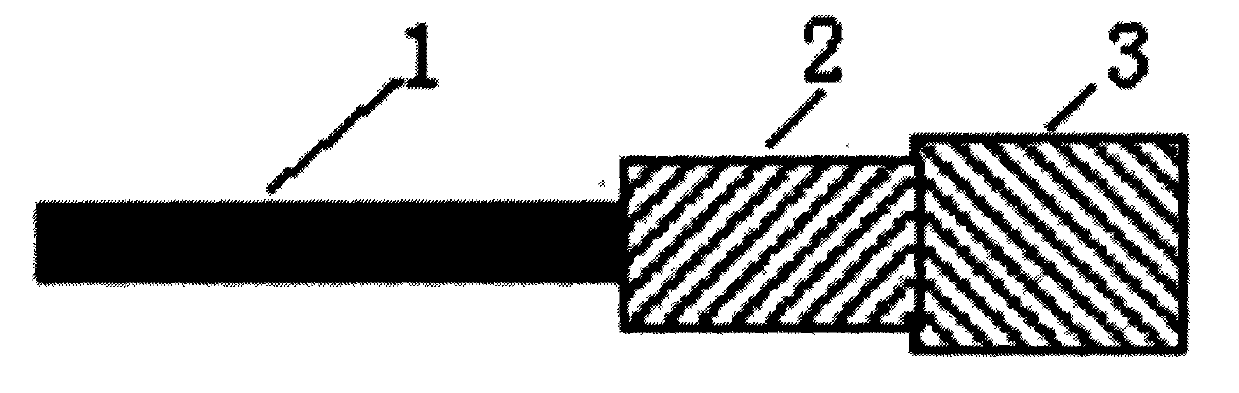

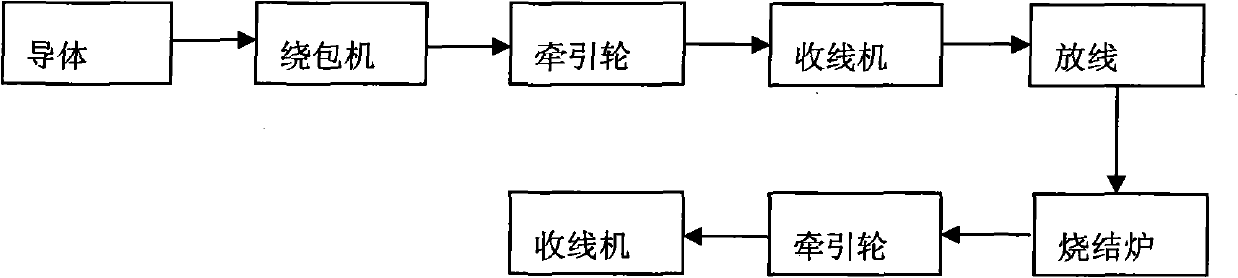

[0031] Regular stranded copper conductor polyimide film is wrapped with high temperature sintering PTFE film is wrapped with high temperature sintering.

Embodiment 2

[0033] Non-regular stranded copper conductor polyimide film is wrapped with high temperature sintering and polytetrafluoroethylene film is wrapped with high temperature sintering.

[0034] Check the appearance of Embodiment 1 and Embodiment 2 through hand touch and visual observation, and no obvious gaps are found; by adjusting the wrapping angle, the theoretical wrapping rate of Embodiment 1 and Embodiment 2 is about 50%. ; Winding test results: when the winding diameter is 1D, neither the first nor the second embodiment has warping or cracking.

[0035] Compared with traditional aviation insulated wires, the wires of the present invention have the characteristics of high temperature resistance and light weight:

[0036]

[0037] Note: The above wire specifications are AWG 22#

Embodiment 3

[0039] According to the change of the diameter of the conductor, the parameters such as the thickness of the polyimide film of the inner insulating layer and the polytetrafluoroethylene film of the outer insulating layer, the wrapping angle, and the width can be changed to control the overlapping rate. As shown in the following table:

[0040]

[0041]

[0042] Compared with other aviation insulated wires, the wire of the invention has the advantage of low cost. Taking AWG22# wire gauge as an example, its manufacturing cost of the electric wire of the present invention is about 80% of polytetrafluoroethylene insulated wire, 30% of PEEK insulated wire, and 30% of radiation cross-linked ethylene-tetrafluoroethylene insulated wire. Strong market competitive advantage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com