Method for efficiently extracting polysaccharide and polyphenol from agaricus blazei

A polysaccharide and high-efficiency technology, applied in the direction of antineoplastic drugs, fermentation, medical raw materials derived from fungi, etc., can solve the problems of protein interference, low extraction rate and activity, waste, etc., and achieve mild conditions, high yield, and purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

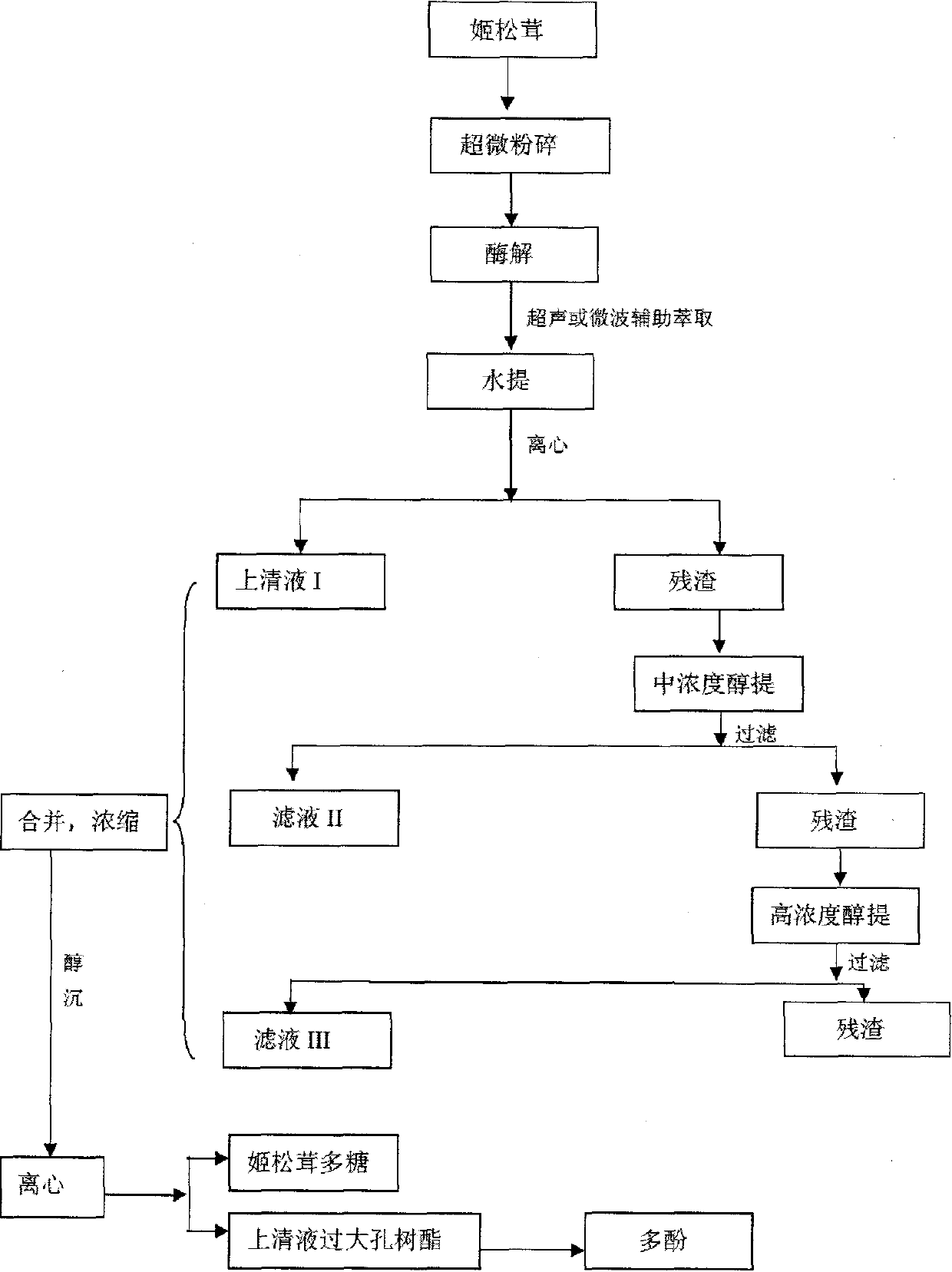

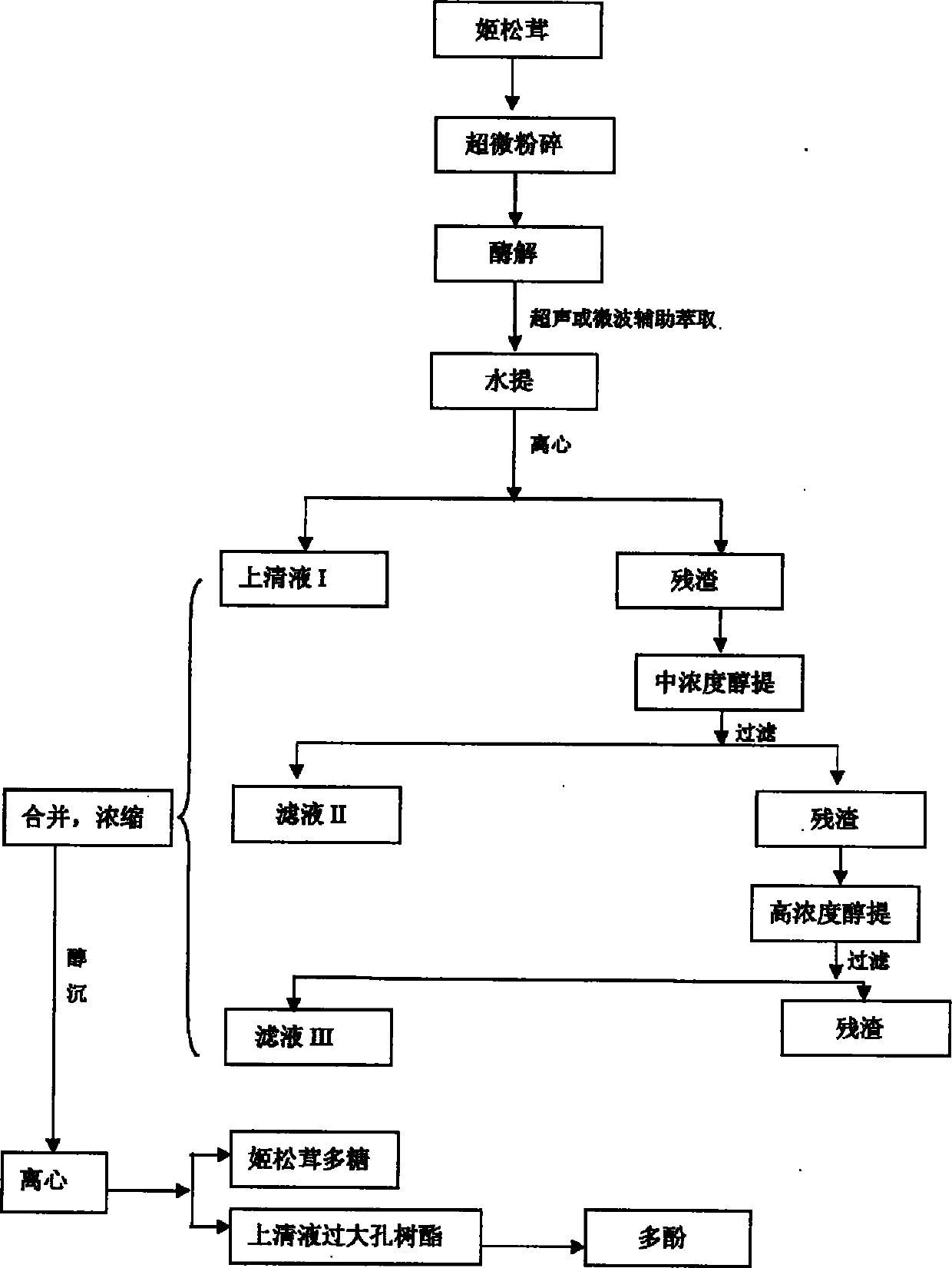

Image

Examples

Embodiment 1

[0035] Embodiment 1: (method 1 for simultaneously efficiently extracting polysaccharides and polyphenols from Agaricus blazei)

[0036] (1) Raw material pretreatment: After the dried Agaricus blazei fruiting body is ultrafinely pulverized, it is mixed with distilled water in a ratio of 1:30 by weight to form a mixed solution, and then set aside;

[0037] (2) Enzymolysis treatment: add the compound enzyme (cellulase: pectinase: neutral protease=3: 1: 4) that accounts for 0.1% of the mixed solution to the mixed solution, adjust the pH of the mixed solution to be 4, and Put it on a shaker at 45°C for 15 minutes;

[0038] (3) Water extraction treatment: Ultrasonic (200Hz, 800W) treatment of the enzymolysis solution in step (2) for 15 minutes, then heating the solution to 90°C, extracting for 30 minutes, and centrifuging at 6000 rpm for 10 minutes , to obtain supernatant I and precipitate;

[0039] (4) Ethanol extraction: step (3) precipitate is mixed with the ethanol that concen...

Embodiment 2

[0043] Embodiment 2: (method 2 for simultaneously efficiently extracting polysaccharides and polyphenols from Agaricus blazei)

[0044] In this example, step (1) mixes Agaricus blazei ultrafinely pulverized fruiting bodies with distilled water at 1:40 by weight; Protease = 4:1:3) was added to the mixture, at 48°C, pH value 4.5, shaken and enzymatically hydrolyzed for 30 minutes; in step (3), the enzymolyzed solution in step (2) was subjected to ultrasonic (400Hz, 200W) treatment for 20 minutes Minutes later, heat the solution to 95°C and extract for 40 minutes; step (4) mix the precipitate in step (3) with ethanol with a concentration of 55% in a ratio of 1 kg by weight and volume: 40 liters, and shake and extract at 85°C 1 hour; extract and filter the filter residue and 95% ethanol according to the above method; the macroporous resin used in step (6) is PN400. All the other steps, technology are with embodiment 1. Under the above conditions, the polysaccharide yield of Agar...

Embodiment 3

[0045] Embodiment 3: (from Agaricus blazei simultaneously and efficiently extract the method 3 of polysaccharide and polyphenol)

[0046]In this example, step (1) mixes Agaricus blazei ultrafinely pulverized fruiting bodies with distilled water at 1:45 by weight; step (2) will account for 0.3% compound enzyme (cellulase: pectinase: neutral Protease = 5:1:2) was added to the mixture, at 50°C, pH value 5, shaking and enzymolysis for 60 minutes; step (3) microwave (50Hz, 800W) treatment of the enzymolysis solution in step (2) for 25 minutes Minutes later, heat the solution to 95°C and extract for 50 minutes; step (4) mix the precipitate in step (3) with ethanol with a concentration of 55% in a ratio of 1 kg by weight and volume: 45 liters, and shake and extract at 85°C 1 hour; extract and filter the filter residue and 95% ethanol according to the above method; the macroporous resin used in step (6) is CDA40. All the other steps, technology are with embodiment 1. Under the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com