Reaction device for producing organic acid and alcohol through synthesis gas fermentation

A technology of reaction device and organic acid, which is applied in the direction of gas production bioreactor, liquid production bioreactor, biochemical cleaning device, etc., can solve the problems of lower substrate utilization rate and low solubility, and achieve easy scale-up and improved utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

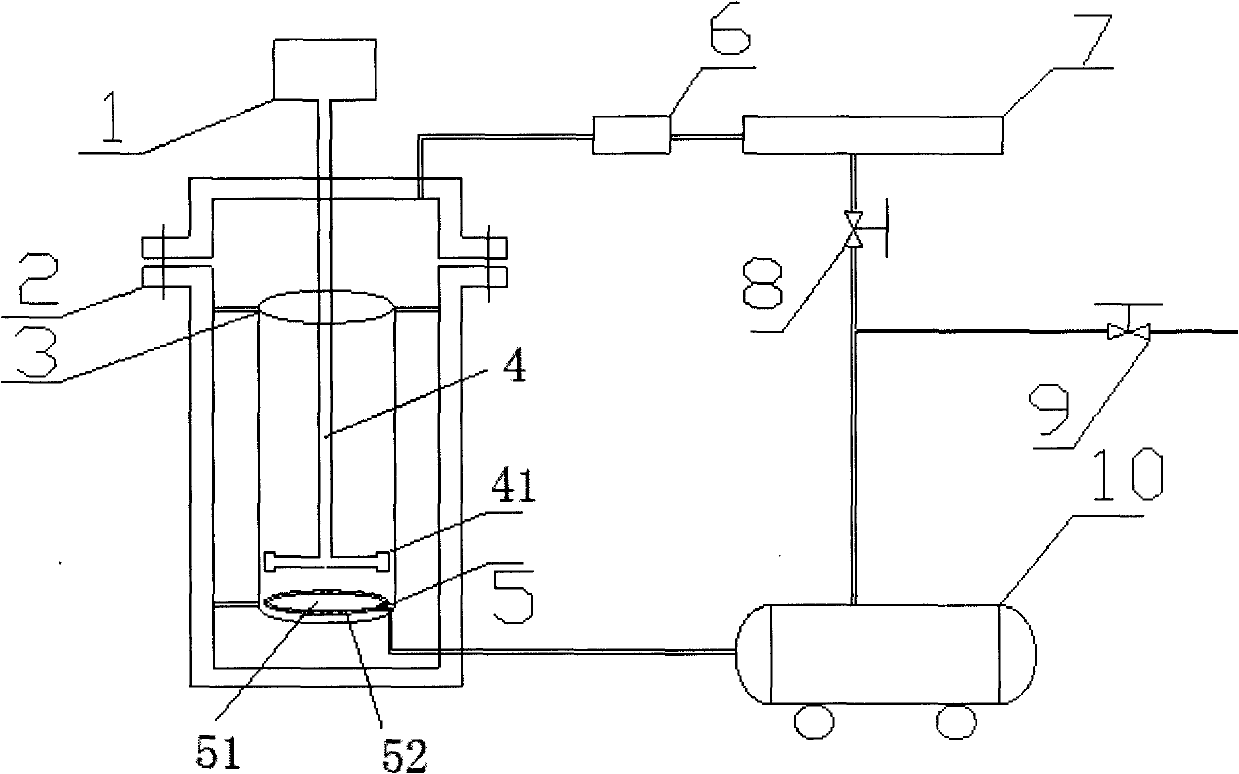

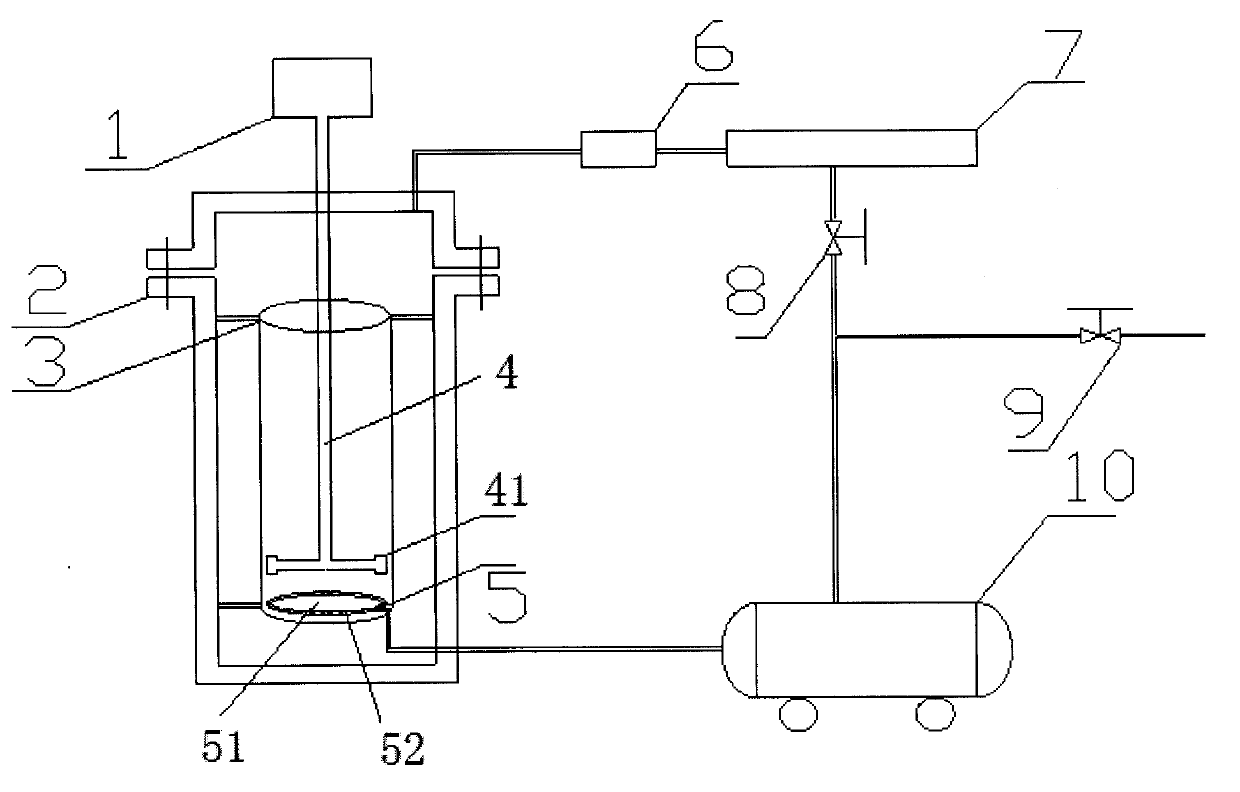

[0018] see figure 1 As shown, a reaction device for syngas fermentation to produce organic acids and alcohols includes a main reactor connected to the main reactor and an external gas circulation system that provides gas circulation for the gas generated in the main reactor. The main reactor includes There is a reactor tank 2, and a guide tube 3 arranged in the reactor tank 2 and fixed by a bracket. The reactor tank 2 is a cylindrical structure with a height-to-diameter ratio of 2 to 3, and the bottom of the tank is oval or conical. Shaped, the top cover is elliptical and connected by flanges, and contains fermentation liquid; the guide tube 3 is a concentric cylinder of the reactor tank 2; along the central axis of the guide tube 3, there is a blade-type agitator 4 One end of the stirrer 4 with stirring blades 41 is arranged close to the bottom end of the guide tube 3, and the other end of the stirrer 4 is connected with a drive motor 1, and the drive motor 1 provides power f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com