Method for extracting crude fish oil in leftovers of tilapia

A technology of leftovers and tilapia, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of reducing the stability of the emulsion, the destruction of active ingredients, and the low extraction rate of fish oil, so as to improve the extraction rate of fish oil and the efficiency of raw materials Utilization rate, low environmental pollution and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

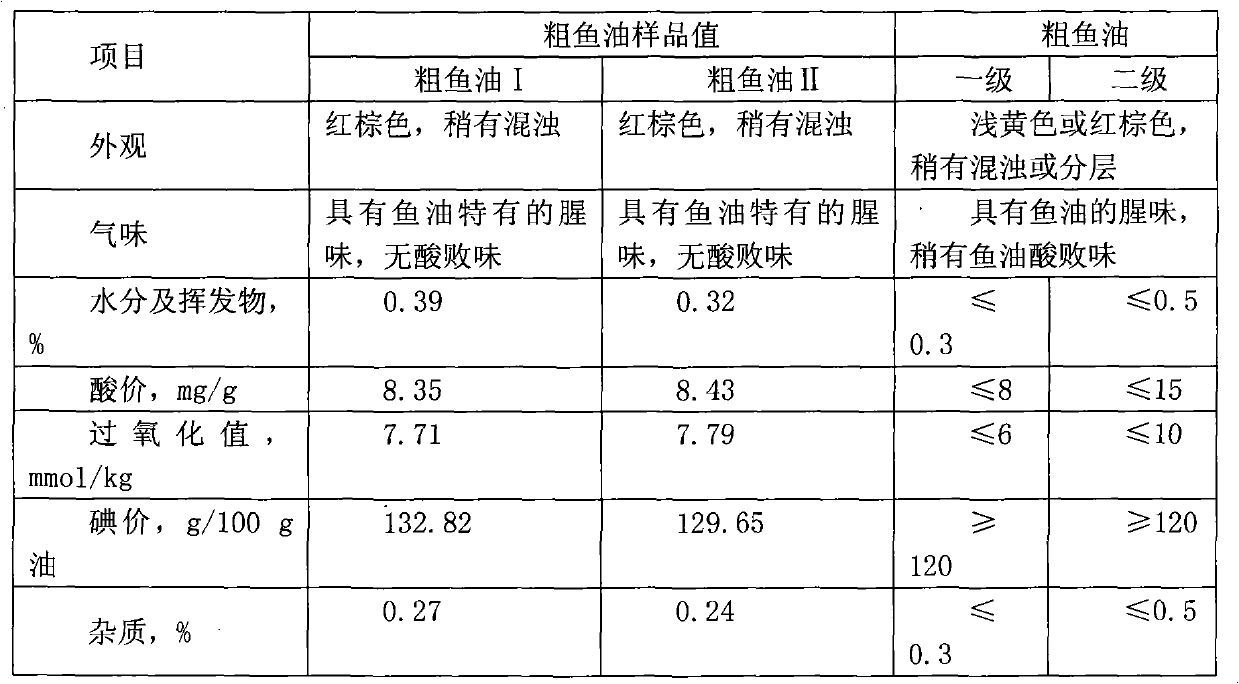

Embodiment 1

[0022] Tilapia processing waste, including viscera, fish maw, and minced meat, after gallbladder removal, sundries removal, cleaning, and meat grinder minced, prepared according to the weight ratio of material to water of 1:2, added to the enzymatic hydrolysis tank Stir at a constant speed of 200r / min, raise the temperature to 50°C, add 1000U / g of Alcalase enzyme for enzymolysis, add acid and alkali solution continuously throughout the enzymolysis process to keep the pH to 7.5, under the optimal enzymolysis conditions of Alcalase enzyme After 2 hours of hydrolysis, Alcalase enzymatic hydrolysis was completed at 90°C, and the enzyme was inactivated for 10 minutes, then the enzymolysis solution was stirred at a constant speed of 200r / min, the temperature was adjusted to 45°C, 1500U / g trypsin was added, and the entire enzymolysis process continued Add acid and alkali solution to keep the pH to 8.0, enzymatically hydrolyze for 2 hours under the best conditions of trypsin enzymolysi...

Embodiment 2

[0024] Tilapia processing waste, including viscera, fish maw, and minced meat, after gallbladder removal, sundries removal, cleaning, and meat grinder minced, prepared according to the weight ratio of material to water of 1:2, added to the enzymatic hydrolysis tank Stir at a constant speed of 250r / min, raise the temperature to 55°C, add 1500U / g of Alcalase enzyme for enzymolysis, add acid and alkali solution continuously throughout the enzymolysis process to keep the pH to 8.0, under the optimal enzymolysis conditions of Alcalase enzyme After 2 hours of hydrolysis, Alcalase enzymatic hydrolysis was completed at 90°C, and the enzyme was inactivated for 10 minutes, then the enzymatic hydrolysis solution was stirred at a constant speed of 250r / min, the temperature was adjusted to 50°C, and 2000U / g trypsin was added, and the entire enzymatic hydrolysis process continued Add acid and alkali solution to keep the pH to 9.0, enzymatically hydrolyze for 2 hours under the best conditions...

Embodiment 3

[0026] Tilapia processing waste, including viscera, fish maw, and minced meat, after gallbladder removal, sundries removal, cleaning, and meat grinder minced, prepared according to the weight ratio of material to water of 1:3, added to the enzymatic hydrolysis tank Stir at a constant speed of 300r / min, raise the temperature to 60°C, add 2000U / g of Alcalase enzyme for enzymolysis, add acid and alkali solution continuously throughout the enzymolysis process to keep the pH to 9.0, under the optimal enzymolysis conditions of Alcalase enzyme After 3 hours of hydrolysis, Alcalase enzyme was deactivated at 95°C for 15 minutes, then the enzymolysis solution was stirred at a constant speed of 300r / min, the temperature was adjusted to 55°C, 2500U / g trypsin was added, and the entire enzymolysis process continued Add acid and alkali solution to keep the pH to 9.5, and enzymatically hydrolyze for 3 hours under the best conditions of trypsin enzymolysis. After the end of trypsin enzymolysis,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com