Lithium titanate for lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as poor specific capacity and cycle stability, improve discharge rate and cycle performance, improve electronic conductivity, and enhance conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to Li 3.95 Mg 0.05 Ti 5 o 12 The mass ratio of each element in is taken as 3gLi respectively 2 CO 3 Powder, 7.5gTiO 2 Put the powder, 0.03g MgO powder, 0.5g glucose and 10-20ml alcohol into the mixing tank, put it into a planetary ball mill for ball milling for 8 hours, take it out and dry it in an oven at 70°C, then put it in a crucible and put it in a box-type sintering furnace , raise the temperature to 650°C at a rate of 4°C / min in an air atmosphere, keep it warm for 6 hours, then continue to raise the temperature to 800°C, keep it warm for 18 hours, and then cool to room temperature with the furnace. Take out the sample and grind it until the particle size range is controlled at 1.5-4μm, and put it in a desiccator for later use.

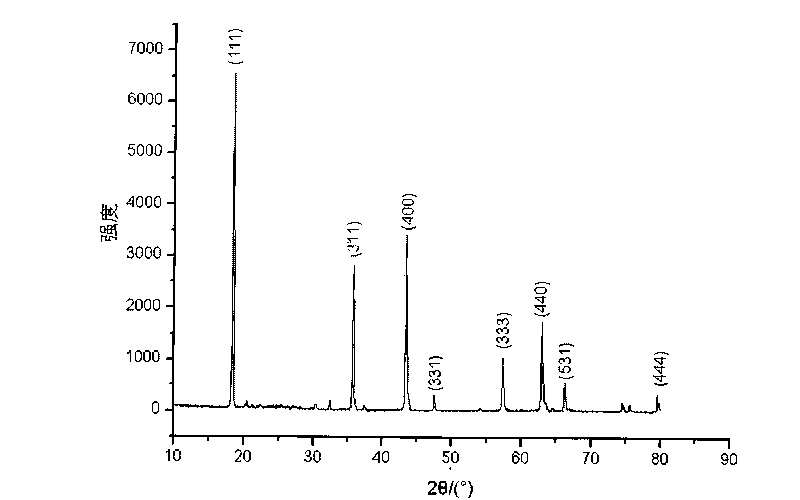

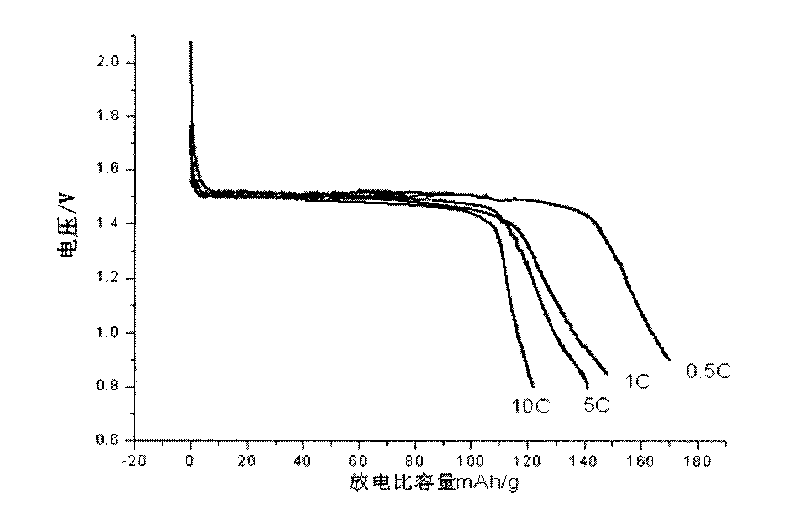

[0020] The sample made above is analyzed through X-ray diffraction (instrument model is Philips X'Pert Pro Super X-ray diffractometer 2θ angle scanning range is 10-80 degree), obtain the X-ray diffraction pattern of the ...

Embodiment 2

[0023] According to Li 3.85 Mg 0.15 Ti 5 o 12 The mass ratio of each element in is taken as 1.962gLi 2 CO 3 Powder, 5.11gTiO 2 Put the powder, 0.075g of MgO powder, 1g of rock sugar and 10-20ml of alcohol into a mixing tank, put it into a planetary ball mill for ball milling for 8 hours, take it out and dry it in an oven at 80°C, then put it in a crucible and place it in a box for sintering In the furnace, heat up to 700°C for 8 hours at a rate of 4°C / min in the air atmosphere, then continue to heat up to 850°C and calcinate in the air atmosphere for 20 hours, take out the sample and grind it finely, and the particle size range is controlled at 1.5-4μm. The obtained sample was a yellow powder.

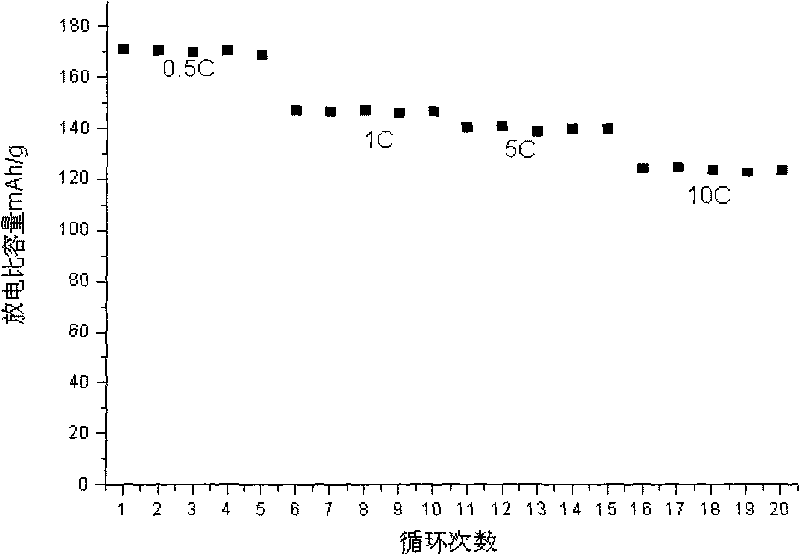

[0024] The battery was assembled and tested according to the same method as in Example 1, and the test results obtained were: the discharge capacity reached 179mAh / g at 0.5C, 150mAh / g at 1C, and 133mAh / g at 5C, and the data at 10C For discharging 120mAh / g, the capacity retention r...

Embodiment 3

[0027] According to Li 3.7 al 0.3 Ti 5 o 12 The mass ratio of each element in is taken as 2g LiNO 3 Powder, 5gTiO 2 Powder, 0.2gAl 2 o 3 Put the powder, 1.5g of citric acid and 10-20ml of alcohol into a mixing tank, put it into a planetary ball mill for ball milling for 8 hours, take it out, dry it in an oven at 90°C, put it in a crucible and place it in a box-type sintering furnace In the air atmosphere, heat up to 600°C at a heating rate of 3°C / min for 10 hours, then continue to heat up to 900°C for 24 hours in an air atmosphere, take out the sample and grind it finely, and the particle size range is controlled at 1.5-4μm.

[0028] Carry out battery assembly and testing according to the same method as in Example 1, it is obtained that the discharge capacity reaches 176mAh / g at 0.5C, 148.6mAh / g at 1C, 134mAh / g at 5C, and 119.2mAh at 10C / g, the obtained data is close to Example 2. It can be seen that the doped lithium titanate material prepared in this example has goo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com