Method for pretreating technical cavity of plasma device

A process chamber and pretreatment technology, which is applied in the direction of metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of poor bonding force between the protective layer and the inner wall of the process chamber, so as to reduce the generation of particle pollutants, High adhesion performance and enhanced corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the mode of "forming fluorine-containing plasma outside the process chamber, and then introducing the fluorine-containing plasma into the process chamber" is described as an example.

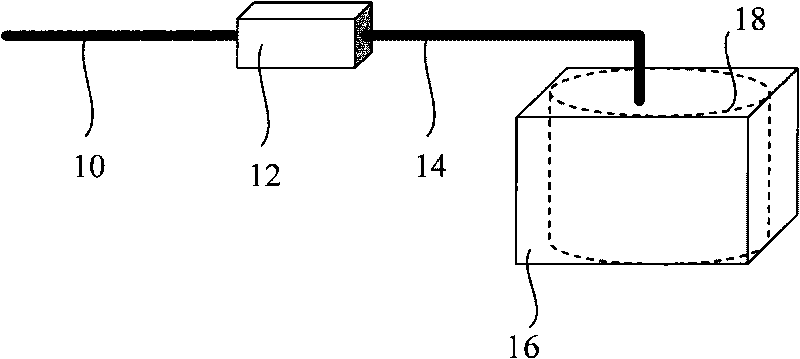

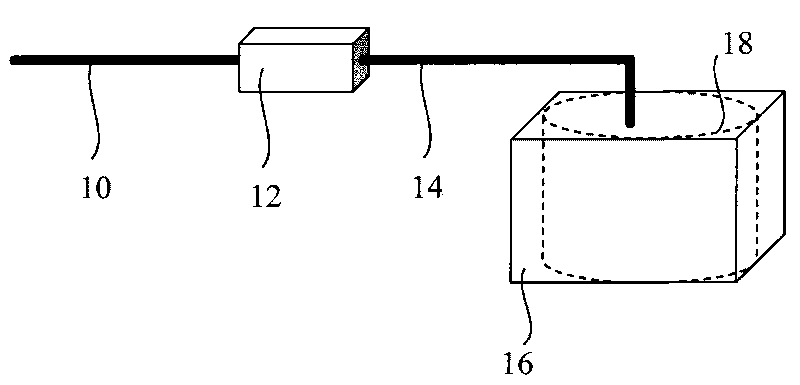

[0047] Please refer to figure 1 , The plasma device process chamber 16 has a lining 18, and the lining 18 is made of aluminum or a material containing aluminum. The lining 18 is the inner wall of the process chamber 16 . There may also be other parts made of aluminum or made of aluminum in the process chamber 16 , for example, an aluminum-based ring, which will not be pointed out here one by one. The plasma device process chamber 16 may also include other components, such as an air intake device, an exhaust device, and workpiece chucks, etc., which will not be listed here.

[0048] Before the plasma pretreatment is performed on the plasma device process chamber 16, at first one end of the plasma conduit 14 is connected to the upper cover inlet of the process chamber ...

Embodiment 2

[0061] In this embodiment, the fluorine-containing plasma is generated in the process chamber that needs pretreatment, and depends on the excitation source of the process chamber to stimulate the ionization of the fluorine-containing gas passing into the process chamber to generate plasma; then, use the plasma to The inner wall of the process chamber and internal components are fluorinated. In the method, the in-situ fluorination treatment is performed after the plasma is generated, the process is simple, and the implementation is convenient. Moreover, the formed aluminum fluorine compound barrier layer has good uniformity in thickness and density, and high adhesion performance.

[0062] As a specific example, the fluorine-containing gas that passes into the process chamber can be CF4, and the flow rate is 500sccm to 1000sccm, and it can certainly be other fluorocarbons; the radio frequency source of the process chamber (in this implementation, the excitation source is a radio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com