Preparation method of seawater corrosion resisting and acid resisting type slag micro-powder and cement baking-free bricks

A technology of slag powder and unburned bricks, which is applied in the field of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

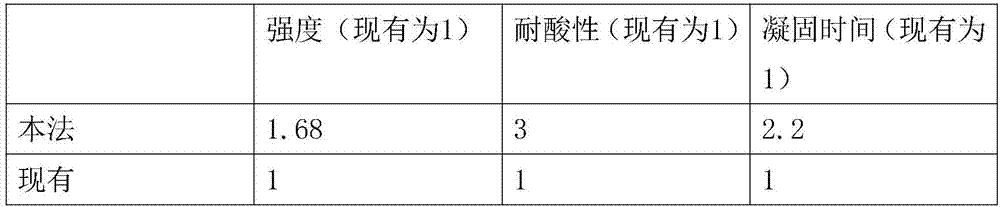

specific Embodiment 1

[0037] A method for preparing non-fired bricks with seawater erosion-resistant acid-resistant slag powder and cement. Put the slag powder in the mixed liquid, stir, cook the mixed liquid at a high temperature of 300°C, filter it after 1 hour, take out the slag powder, mix it with the cement, and then Add 50% of the amount of water and continue to stir to obtain the mixture;

[0038] The adobe is obtained by vibrating the mixture, and the adobe is cured at room temperature to obtain a slag powder unburned brick;

[0039] Specific steps are as follows:

[0040] Take the modified epoxy resin and put it into the reaction kettle, stir and raise the temperature to 85°C, then dropwise add the mixed solution of acrylic acid, epichlorohydrin and hydroquinone, stir and react for 4-5 hours, and obtain the preform A;

[0041] Take talc powder and add it to the reaction kettle, heat to 130°C while stirring and vacuuming, and keep it warm for 1 hour; then cool to 80°C, add titanium dioxide...

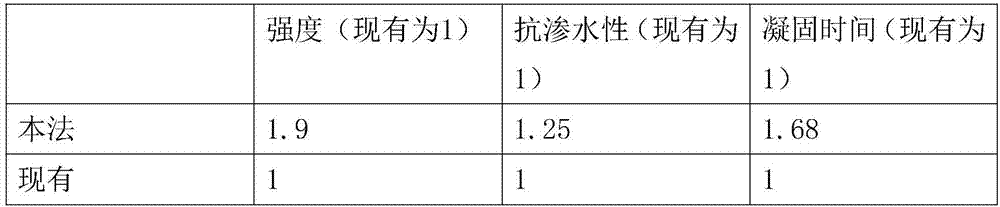

Embodiment 2

[0069] Example 2: A method for preparing unfired bricks with seawater erosion-resistant acid-resistant slag powder and cement. Put the slag powder in the mixed solution, stir, cook the mixed solution at 300°C for 1 hour, filter, take out the slag powder, and mix with the cement Mix and stir, then add 50% of the water and continue to stir to obtain the mixture;

[0070] The adobe is obtained by vibrating the mixture, and the adobe is cured at room temperature to obtain a slag powder unburned brick;

[0071] Specific steps are as follows:

[0072] Take the modified epoxy resin and put it into the reaction kettle, stir and raise the temperature to 85°C, then dropwise add the mixed solution of acrylic acid, epichlorohydrin and hydroquinone, stir and react for 4-5 hours, and obtain the preform A;

[0073] Take talc powder and add it to the reaction kettle, heat to 130°C while stirring and vacuuming, and keep it warm for 1 hour; then cool to 80°C, add titanium dioxide dropwise to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com