Compound modified biomass fibrilia and preparation method thereof

A composite modification and biomass technology, applied in the fields of plant fiber, fiber treatment, textile and paper making, etc., can solve the problem of poor performance of natural biological hemp fiber/polymer composite material, and the inconsistency of the interface between the polarity of hemp fiber and polymer polarity. Compatibility, low interface bonding force and other problems, to achieve the effects of excellent efficacy, easy control of process parameters, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

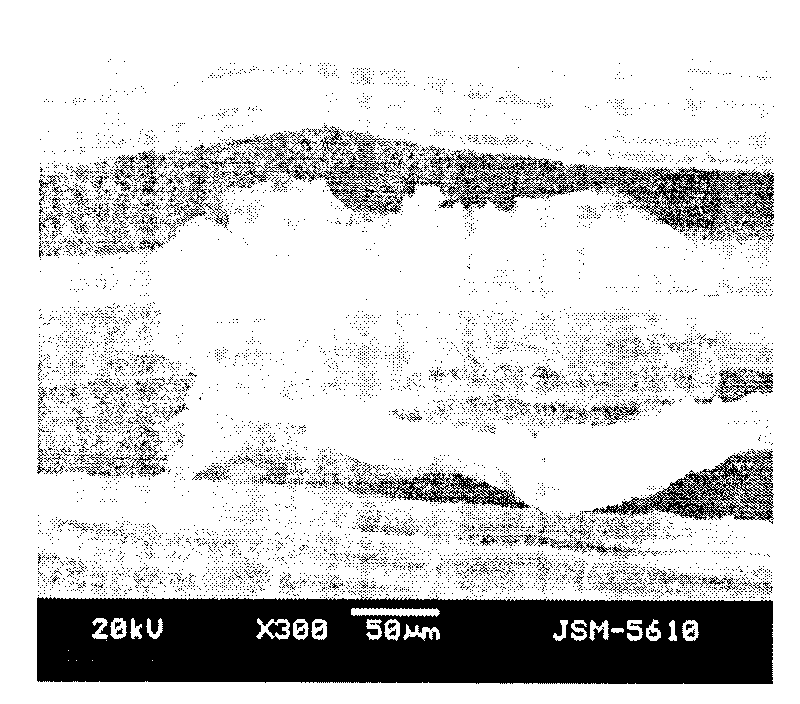

Image

Examples

Embodiment 1

[0036] 1. Take by weighing 2.667g lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 (0), dissolve the weighed lanthanum nitrate hexahydrate in 2Kg hot water (50-60°C) under medium-speed magnetic stirring, and keep stirring until the lanthanum nitrate hexahydrate dissolves completely;

[0037] 2. Weigh 0.5Kg of ramie fibers rinsed with clear water and dried, put them into the prepared rare earth solution and soak for 1-2 hours, then remove and dry;

[0038] 3. take by weighing 1Kg maleic anhydride grafted polypropylene (KRD series maleic anhydride grafted polypropylene, Qinhuangdao Keruida Macromolecular Material Co., Ltd., the same as the following examples), melt and mix with The ramie after rare earth treatment is bonded. Under the conditions of extrusion temperature 175-185 ° C and extrusion pressure 38-45 bar, the rare earth modified ramie fiber is drawn into the extruder at a screw speed of 80 rpm and is extruded by maleic anhydride. Grafted polypropylene sheath.

[00...

Embodiment 2

[0041] 1. Weigh 6g lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 (0), the weighed lanthanum nitrate hexahydrate is dissolved in 1.5Kg hot water (50-60° C.) under medium-speed magnetic stirring, and the stirring is continued until the lanthanum nitrate hexahydrate is completely dissolved;

[0042] 2. Weigh 500g of ramie fibers rinsed with clear water and dried, put them into the prepared rare earth solution and soak for 1-2 hours, then remove and dry;

[0043] 3. Weigh 1Kg of maleic anhydride grafted polypropylene, melt it in a single-screw extruder and bond it with the ramie after rare earth treatment, at an extrusion temperature of 175-185°C and an extrusion pressure of 38-45bar, Rare-earth modified ramie fibers are drawn into the extruder at a screw speed of 75 rpm and coated with maleic anhydride-grafted polypropylene.

[0044] 4. The hemp fiber coated with rare earth grafted and compounded is rolled to a uniform surface, cooled, solidified at room temperature, and dr...

Embodiment 3

[0046] 1. Take by weighing 13.33g lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 (0), dissolve the weighed lanthanum nitrate hexahydrate in 2Kg hot water (50-60°C) under medium-speed magnetic stirring, and keep stirring until the lanthanum nitrate hexahydrate dissolves completely;

[0047] 2. Weigh 1Kg of ramie fibers rinsed with clear water and dried, put them into the prepared rare earth solution and soak for 1-2 hours, then remove and dry;

[0048] 3. Weigh 2Kg of maleic anhydride grafted polypropylene, melt it in a single-screw extruder and bond it with rare earth-treated ramie, at an extrusion temperature of 175-185°C and an extrusion pressure of 38-45bar, Rare-earth modified ramie fibers are drawn into the extruder at a screw speed of 70 rpm and coated with maleic anhydride-grafted polypropylene.

[0049] 4. The hemp fiber coated with rare earth grafted and compounded is rolled to a uniform surface, cooled, solidified at room temperature, and dried to obtain the nat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com