Method for making rare earth elements uniformly distributed on surface of aluminum-silicon alloy

An aluminum-silicon alloy, surface uniform technology, applied in the field of materials, can solve problems such as the influence of alloy properties, limit the expected metamorphic effect of the alloy, etc., and achieve the effects of uniform surface composition, uniform distribution of rare earth composition, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The aluminum-silicon alloy composition used is Al-12.6Si-1Nd.

[0024] The above-mentioned aluminum-silicon alloy is cut out by wire cutting, and the surface of the section of the aluminum-silicon alloy ingot is ground and polished; then the surface of the ingot is cleaned with an organic solvent, and the organic solvent on the surface of the ingot is removed.

[0025] Place the aluminum-silicon alloy ingot after surface pretreatment in the Nadezhda-2 high-current pulsed electron beam equipment, in a vacuum degree ≤ 10 -3 Under the condition of Pa, the high-current pulsed electron beam is applied to modify the surface of the cross-section. The working parameters of the high-current pulsed electron beam are: the acceleration voltage is 23kV, the number of pulses is 15 times, and the processing time is 15μs. The specific heating and cooling process is completed in the alloy surface modification layer, and the heating rate is 10 7 ~10 8 K / s, the solidification rate reach...

Embodiment 2

[0031] The aluminum silicon alloy that adopts is the same as embodiment 1.

[0032] The surface pretreatment method that adopts is with embodiment 1.

[0033] The electron beam heat treatment method adopted is the same as that in Embodiment 1, except that the number of pulses is 25 and the treatment time is 25 μs. The wear resistance of the treated aluminum-silicon alloy section is increased by 2 to 3 times. Compared with the number of pulses in Example 1, which was 15 times, the distribution of the rare earth element Nd on the surface of the aluminum-silicon alloy after treatment is more uniform.

Embodiment 3

[0035] The composition of the aluminum-silicon alloy is Al-17.5Si-0.3Nd.

[0036] The surface pretreatment method that adopts is with embodiment 1.

[0037] The electron beam heat treatment method that adopts is the same as embodiment 1.

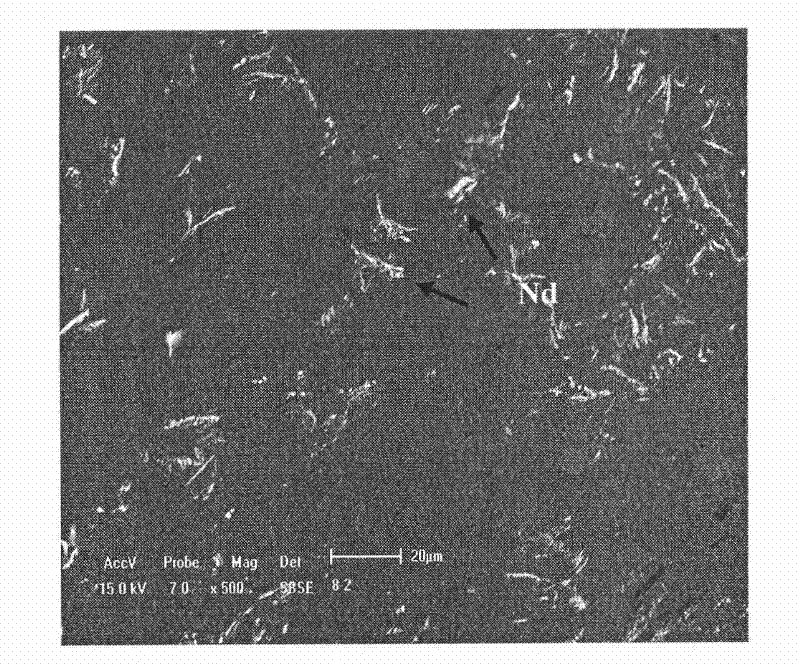

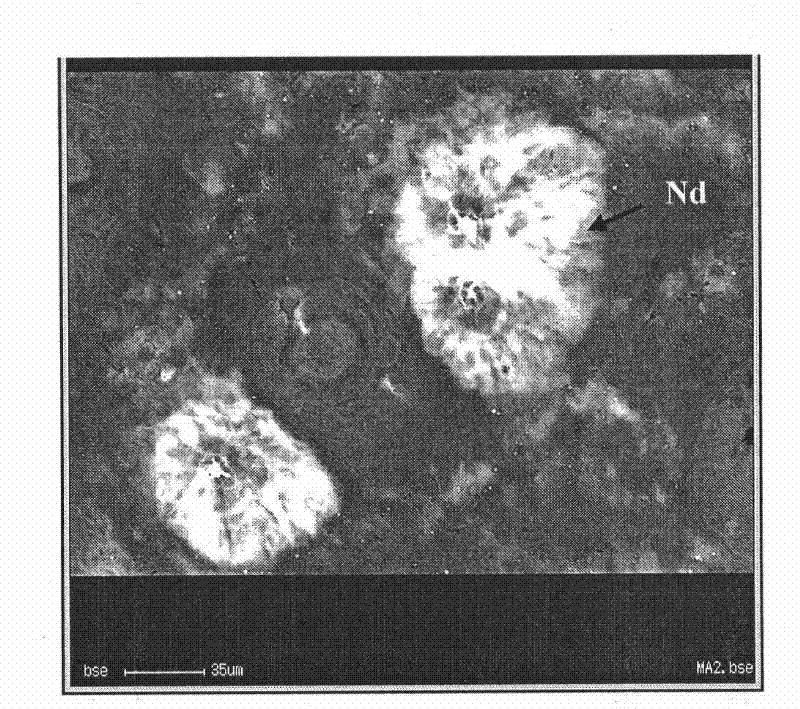

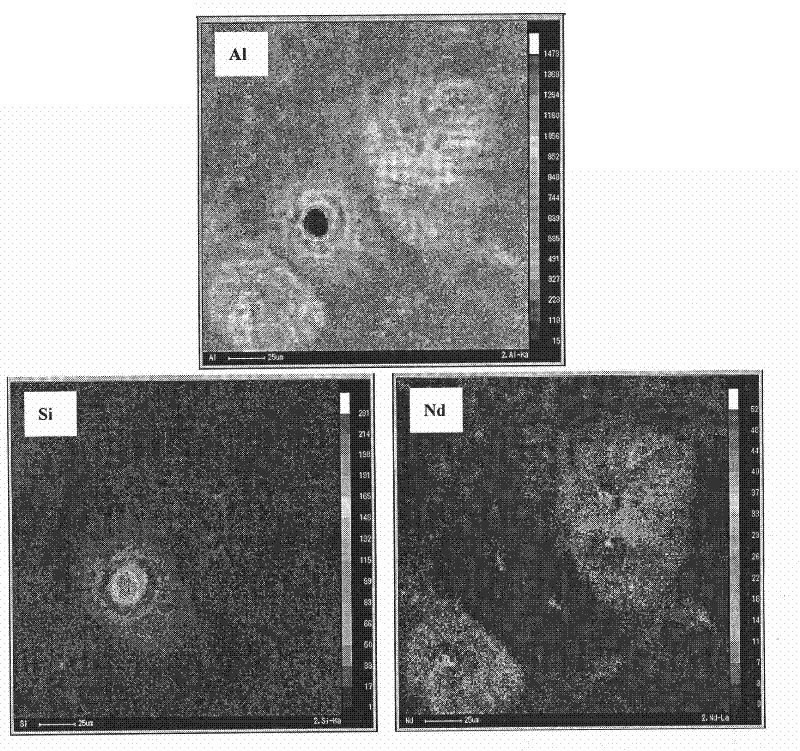

[0038] The surface morphology of the alloy after electron beam treatment was observed by means of SEM, and the microstructure and surface composition changes were as follows: Figure 5As shown, it can be seen from the figure that the rare earth element Nd, which presents a dotted distribution on the surface of the untreated sample (due to the reduction in the amount of Nd added), still presents a "cloud" distribution due to diffusion after the electron beam bombards the alloy surface. The problem of Nd element segregation in cast alloy microstructure is solved. In addition, the modification of the electron beam can refine the surface structure of the alloy and redistribute the chemical elements, all of which are conducive to the realizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com