Guide vane device for pump

A guide vane device and guide vane technology, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as large particle size, complex process, and poor particle size and shape, and reduce production costs. , reduce the process flow, and have good particle size and morphology

Inactive Publication Date: 2012-05-09

诸小莉

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the powder processed by the existing domestic jet mill still has the following defects: one is that the particle size is still relatively large, and there are still many coarse particles of 25 microns; the other is that the particle size distribution and particle size uniformity are not good enough; the third is that The particle size and morphology are poor, and most of them are sharp-edged; the fourth is that the finished product is oxidized, and the finer the powder, the more serious the oxidation phenomenon, which becomes an irreconcilable contradiction

However, the energy consumption and cost of these methods are high, the process is complicated, and there may be instability in the preparation process, and the results are difficult to control.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

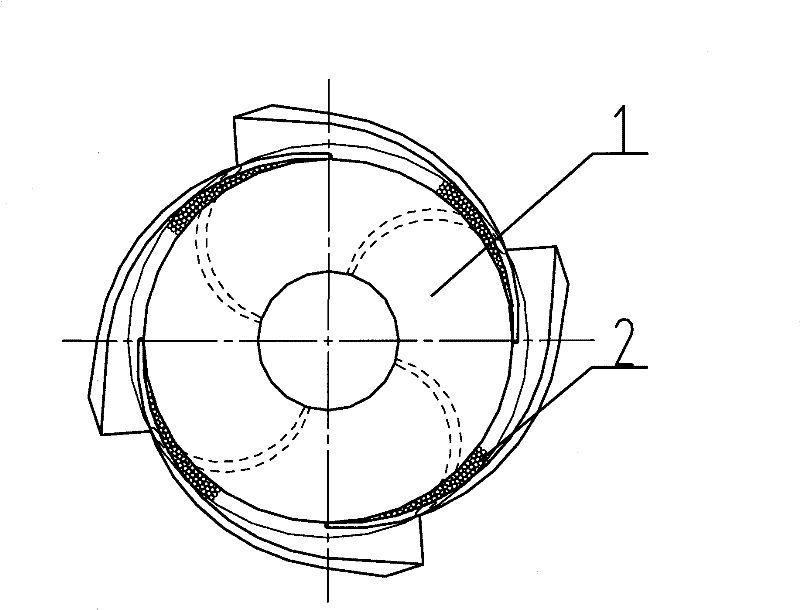

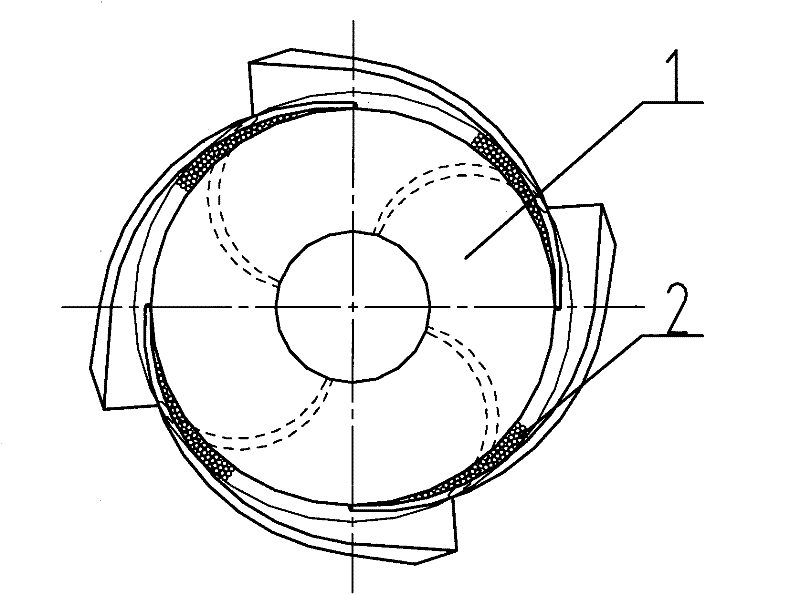

[0013] from figure 1 It can be seen from the figure that a guide vane device for a pump includes a guide vane body 1, and is characterized in that at the outlet of the guide vane body 1, a filter screen 2 composed of several uniformly distributed pores is arranged.

[0014] According to the level of the nanopump and the particle size of the required solid particles, the pore density of the filter screen is between 1000--2500 mesh.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a guide vane device for a pump capable of milling solid particles in solution to be nanoscale. A filter mesh composed of a plurality of uniformly-distributed thin holes and disposed at the guide vane outlet of a present multistage chemical centrifugal pump is utilized, and the density of the thin hole achieves 1000 to 2500 meshes. The particles are directly milled stage by stage during a convey process, so that the conveyed solid particles achieve nanoscale, and the particle size can achieve 0.3 mum at least; and a manufacturer can reduce process flows and have no need to purchase devices such as a jet mill, thereby decreasing production cost. The particles after a multistage milling are uniform in particle size and good in shape by utilizing the nano-pump; and the milling is performed in solution without a phenomenon of oxidization. The pump can be widely applied to mill various kinds of solution containing a mica powder, a graphite powder, a metal powder etc.

Description

technical field [0001] The invention relates to a multi-stage chemical centrifugal pump for conveying various solutions containing mica powder, graphite powder and metal powder, especially a multi-stage chemical centrifugal pump capable of grinding solid particles in the solution into nanoscale Use guide vanes. Background technique [0002] With the continuous development of science and technology, the particle size requirements of various powders such as graphite powder and mica powder are getting higher and higher, and some even reach the nanometer level. For example, graphite powder is a widely used material, which can be used as raw materials for casting materials, refractory materials, dyes, electrode pastes, etc. According to the different requirements for graphite materials, the particle diameter of graphite powder also varies greatly. Nano-graphite powder is a new type of material with high electrical conductivity, thermal conductivity, high lubrication, stealth, s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04D29/44F04D29/70

Inventor 诸小莉

Owner 诸小莉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com