Method for directly manufacturing mineral wool by smelting yellow phosphorus slags

A yellow phosphorus slag, direct technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., can solve the problems of easy pulverization, poor water resistance, unstable fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

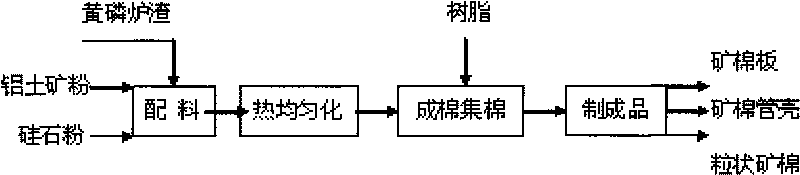

Method used

Image

Examples

Embodiment 1

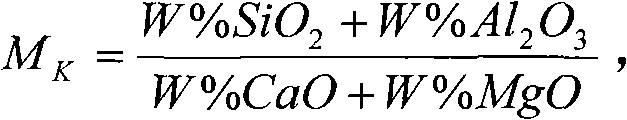

[0011] The electric furnace power of a domestic yellow phosphorus factory is 1500KVA. The composition of molten slag is shown in Table-1 (sampling and analysis after cooling).

[0012] Table-1 yellow phosphorus slag chemical composition weight (%)

[0013]

[0014] Near the slag outlet, add bauxite powder, clay powder and silica powder at a constant speed, and the mixture flows into a rectangular homogenized electric furnace, inserting three 200×40 mm pure iron rod electrodes in the furnace, and the heating material is controlled by a voltage regulating transformer When the temperature reaches 1400±50°C, the electrode consumption is continuously inserted and replenished. Two water-cooled corundum stirrers are installed at the front 1 / 3 of the furnace to homogenize the melt components. The bottom of the discharge port of the electric furnace is aligned with the entrance of the four-roller centrifuge, and the mineral wool is made by centrifugal spinning, and the slag balls a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com