Compound powdery deodorant bacterial poison eliminating agent and preparation method thereof

A technology for deodorization and poisoning, which is applied in the directions of disinfectants, botanical equipment and methods, and disinfection. Overcome the effects of high production costs, less erosion and corrosion, and fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

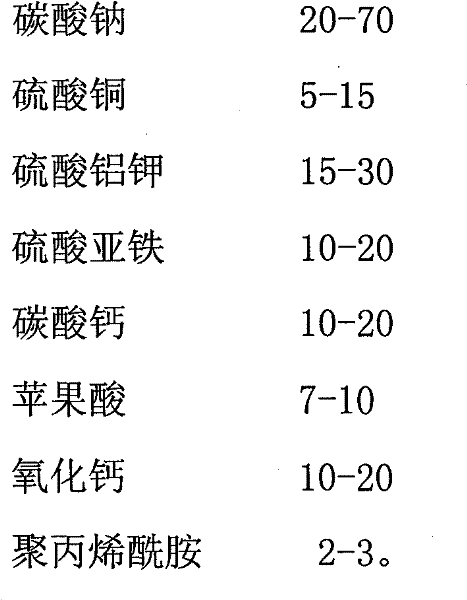

Method used

Image

Examples

Embodiment 1

[0037] Mix 8 parts by weight of 80 mesh malic acid with 30 parts by weight of 80 mesh aluminum potassium sulfate for 40 minutes, then add 20 parts by weight of 80 mesh sodium carbonate, mix for 50 minutes, then add 10 parts by weight of 80 mesh copper sulfate, mix for 40 minutes, and then Add 10 parts by weight of 80 mesh calcium carbonate and mix for 40 minutes, then add 10 parts by weight of 80 mesh ferrous sulfate, mix for 40 minutes, then add 10 parts by weight of 80 mesh calcium oxide and mix for 40 minutes, then add 2 parts by weight of 80 mesh polyacrylamide , mixed for 120 minutes.

Embodiment 2

[0039] Mix 7 parts by weight of 200 mesh malic acid and 10 parts by weight of 200 mesh ferrous sulfate for 50 minutes, then add 24 parts by weight of 300 mesh sodium carbonate, mix for 90 minutes, then add 12 parts by weight of 200 mesh calcium carbonate, mix for 60 minutes, then add 15 parts by weight of 100 mesh copper sulfate were mixed for 50 minutes, then 15 parts by weight of 300 mesh potassium aluminum sulfate were added, mixed for 50 minutes, then 15 parts by weight of 400 mesh calcium oxide were added and mixed for 50 minutes, then 2.5 parts by weight of 200 mesh polyacrylamide was added, Mix for 130 minutes and that's it.

Embodiment 3

[0041] Mix 10 parts by weight of 400 mesh malic acid with 5 parts by weight of 400 mesh copper sulfate for 60 minutes, then add 70 parts by weight of 400 mesh sodium carbonate, mix for 130 minutes, then add 15 parts by weight of 400 mesh aluminum potassium sulfate, mix for 60 minutes, then Add 20 parts by weight of 400 mesh calcium carbonate and mix for 60 minutes, then add 20 parts by weight of 400 mesh ferrous sulfate, mix for 60 minutes, then add 20 parts by weight of 300 mesh calcium oxide and mix for 60 minutes, then add 3 parts by weight of 400 mesh polyacrylamide , mixed for 150 minutes.

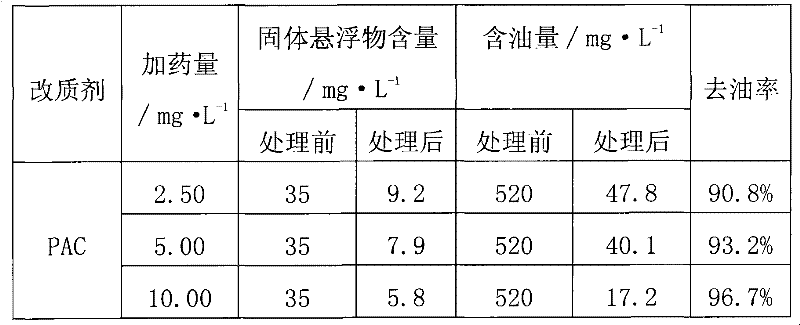

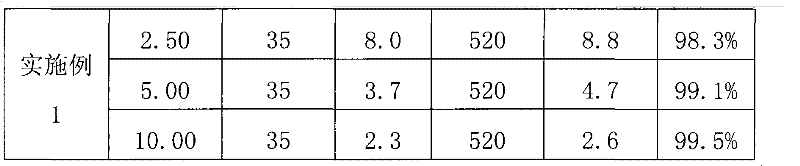

[0042] The technical index of embodiment 1-3 is as shown in table 1:

[0043] Table 1:

[0044] Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com