Composition for cleaning and rust prevention and process for producing semiconductor element or display element

A technology for display elements and compositions, which is applied in the manufacture of semiconductor/solid-state devices, the preparation of anti-corrosion compositions, and the preparation of detergent mixture compositions, etc., can solve problems such as no method for removing anti-corrosion agents disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20 and comparative example 1~20

[0067] The antiseptic components shown in the following Tables 1 and 2 were mixed with the following detergent components to prepare the cleaning and antiseptic compositions of Examples 1-20 and Comparative Examples 1-20. Using these cleaning and antiseptic compositions, the following evaluations were performed.

[0068] (cleaning agent ingredients)

[0069] Liquid A: 0.4% by mass of ammonium fluoride, 0.03% by mass of glyoxylic acid, the balance of water

[0070] Liquid B: 12% by mass of acetic acid, 15.2% by mass of ammonium acetate, 57.5% by mass of dimethylacetamide, 1% by mass of ammonium fluoride, and the balance of water

[0071] Liquid C: 3.4% by mass of oxalic acid, 0.05% by mass of ascorbic acid, the balance of water

[0072] Liquid D: 0.1% by mass of 1,2-diaminopropane, 0.5% by mass of tetramethylammonium fluoride, 1.5% by mass of acetic acid, the balance of water

[0073] (Evaluation 1: Cleanability)

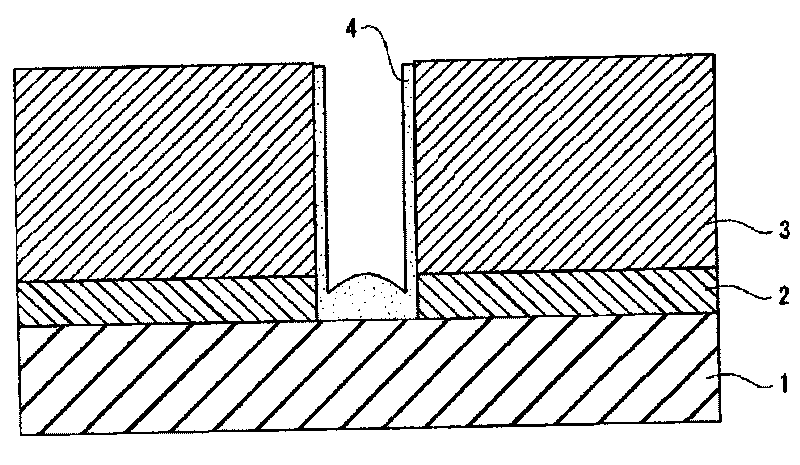

[0074] Will figure 1The shown semiconductor elements were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com