Electromobile control device

A technology of electric vehicle control and equipment, applied in the field of electric vehicles, can solve the problems of large output power of control equipment, operation failure, poor heat dissipation performance, etc., to ensure the installation in place, ensure long-term work, and improve the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

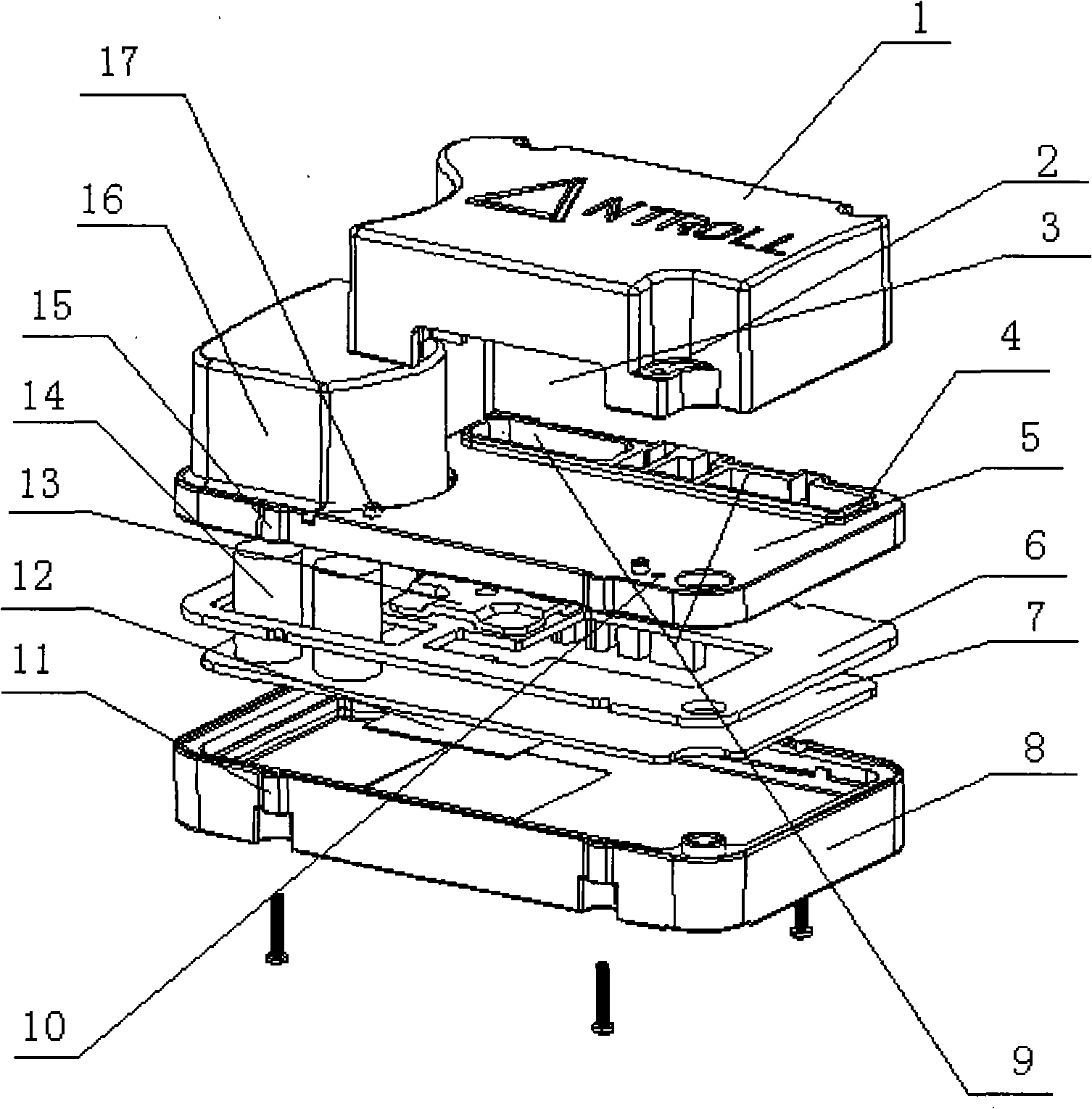

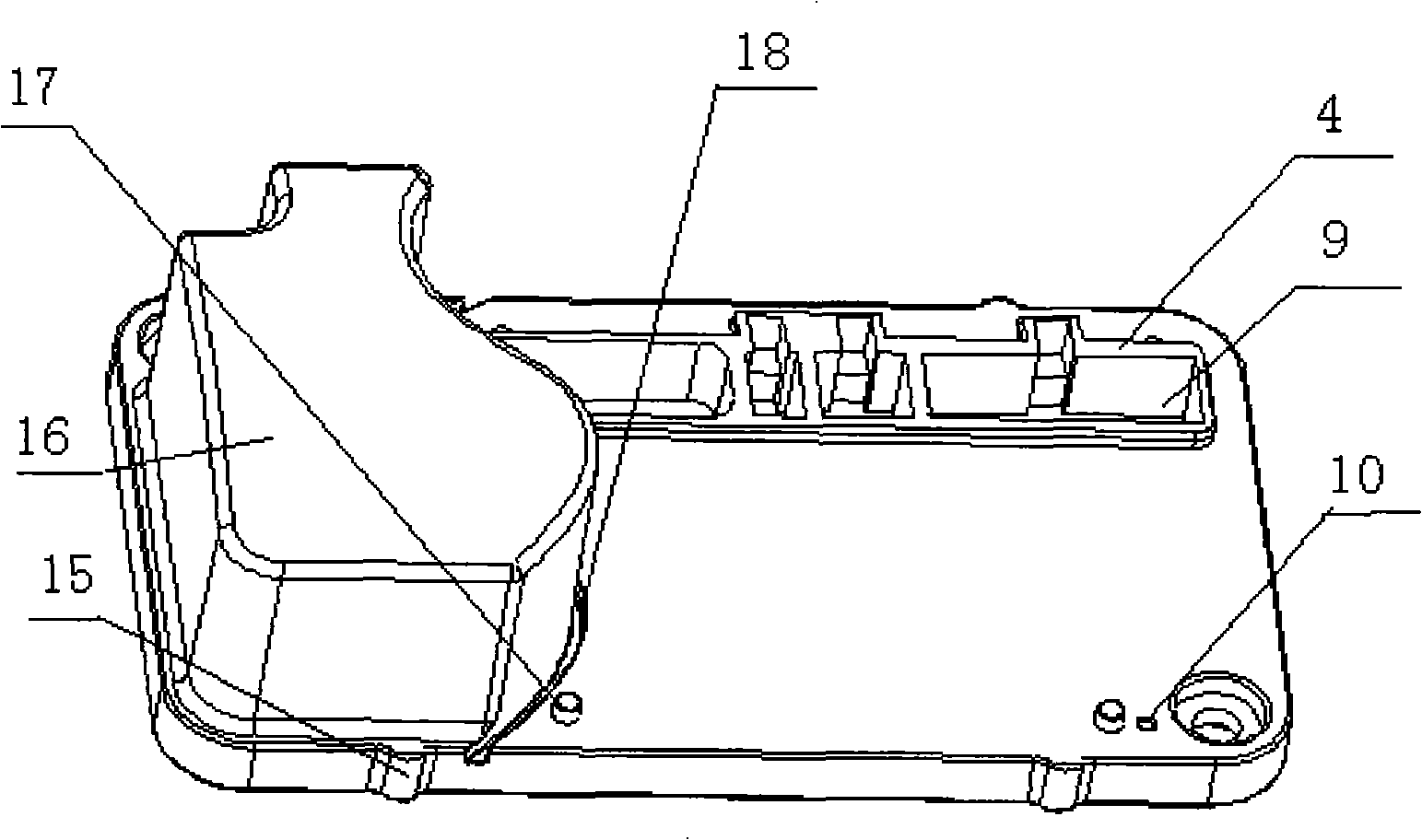

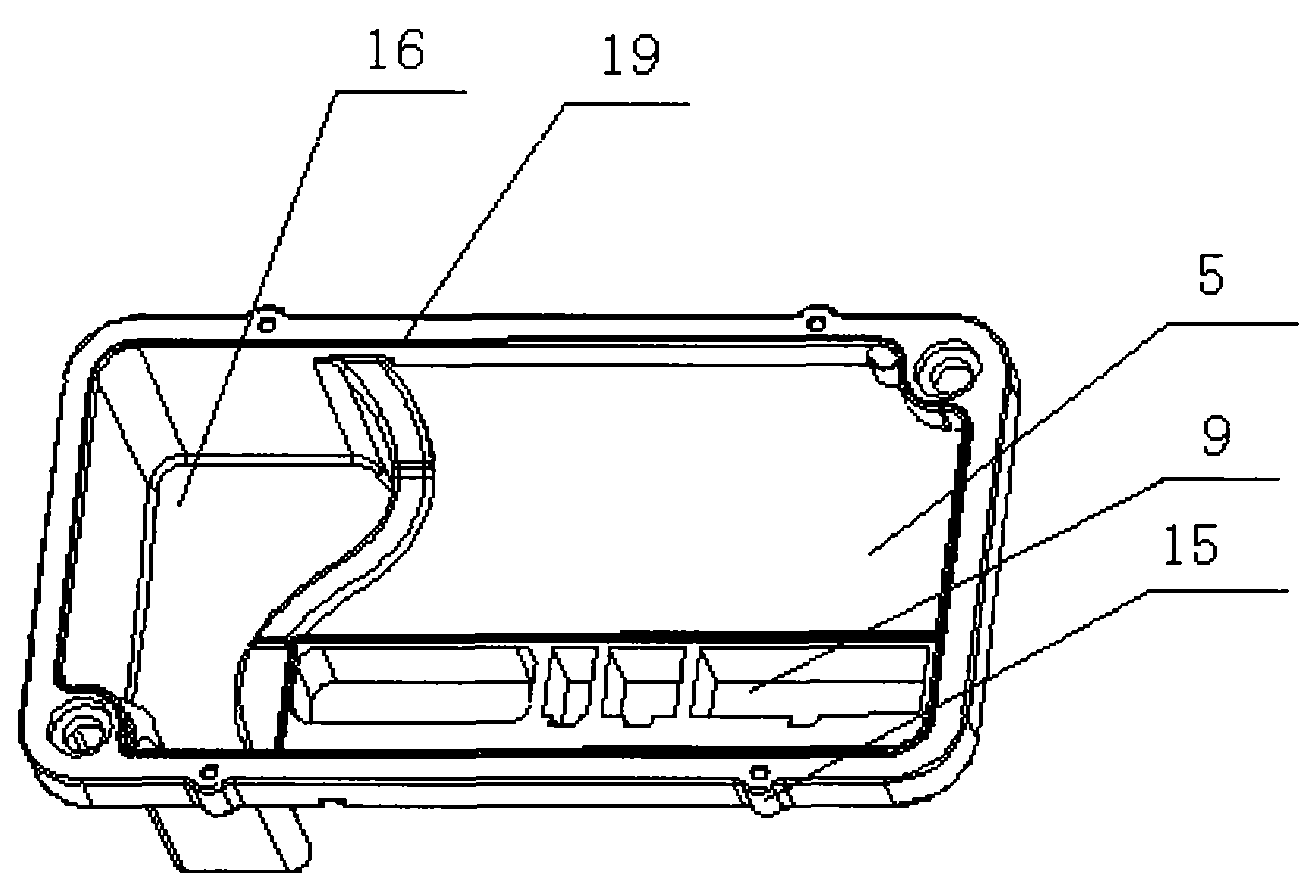

[0022] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0023] Such as Figure 1-8 As shown, 1 is the waterproof cover, 2 is the screw hole, 3 is the outlet hole, 4 is the water shield, 5 is the upper cover, 6 is the gasket, 7 is the circuit board, 8 is the bottom shell, and 9 is the outlet connector. Through hole, 10 is the screw hole, 11 is the screw hole, 12 is the cooling pad, 13 is the pressure plate, 14 is the connector, 15 is the screw hole, 16 is the cavity, 17 is the positioning pin, 18 is the water guide groove, 19 is the convex Rib, 20 is the bracket, 21 is the limit protrusion, 22 is the screw hole, 23 is the positioning groove, 24 is the screw hole, 25 is the threaded connector, 26 is the power tube, 27 is the screw hole, 28 is the depression place.

[0024] The electric vehicle control device of the present invention comprises an upper cover 5 and a bottom case 8, a circuit board 7 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com