Pipe joint of skin-effect electric heating element

A skin effect, electric heat tracing technology, applied in the connection of shape memory materials, etc., can solve the problems of large quantity, long construction period, affecting the skin heating current channel, etc., and achieve the effect of simple operation tools and reliable air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

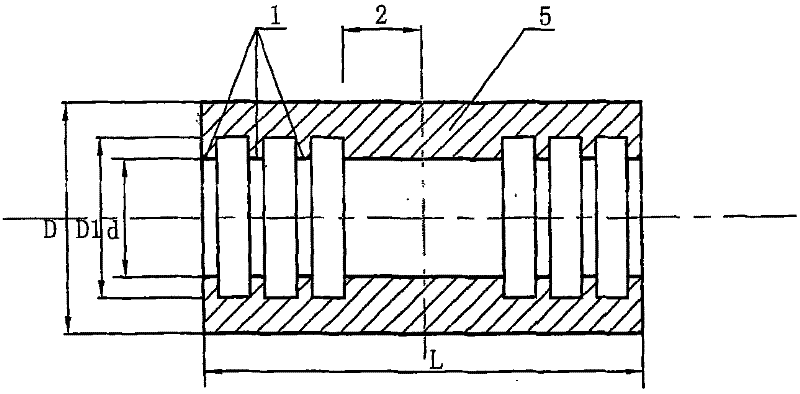

[0018] attached figure 1 It is a schematic diagram of the pipe joint structure made of iron-based memory alloy material in the embodiment of the present invention. The blank material of the pipe joint 5 is made of Ф40mm×160mm iron-based memory alloy material, which is used to connect the skin effect electric heating element The pipe joint 5 of the Ф27mm×4mm heat pipe is based on the "constraint recovery" characteristic of the iron-based memory alloy material. Dislocation, plastic expansion, inhibition of phase transition displacement, mechanical processing, stable shape and other processes are used to manufacture pipe joint products with an outer diameter D of Ф35.5mm and an inner diameter d of 27.5mm and a length L of 140mm. In order to make the seal between the two To ensure that it does not leak, three fastening collars 1 are respectively made on both sides of (d1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com