Smelting furnace

A furnace and furnace chamber technology, applied in the field of kiln equipment and metallurgy, can solve the problems of energy waste, high flue gas temperature, and increase the cost of steelmaking, and achieve the effects of reducing energy consumption, uniform temperature, and improving combustion power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

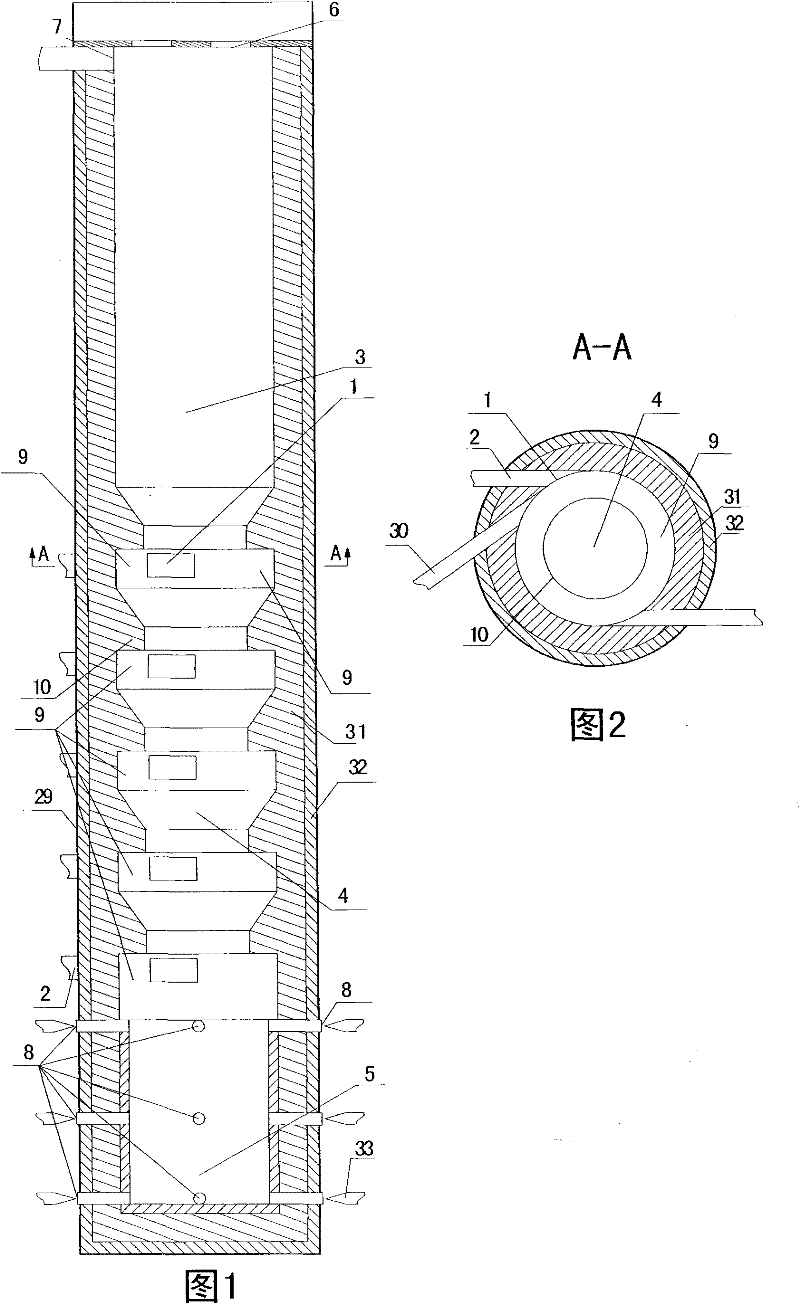

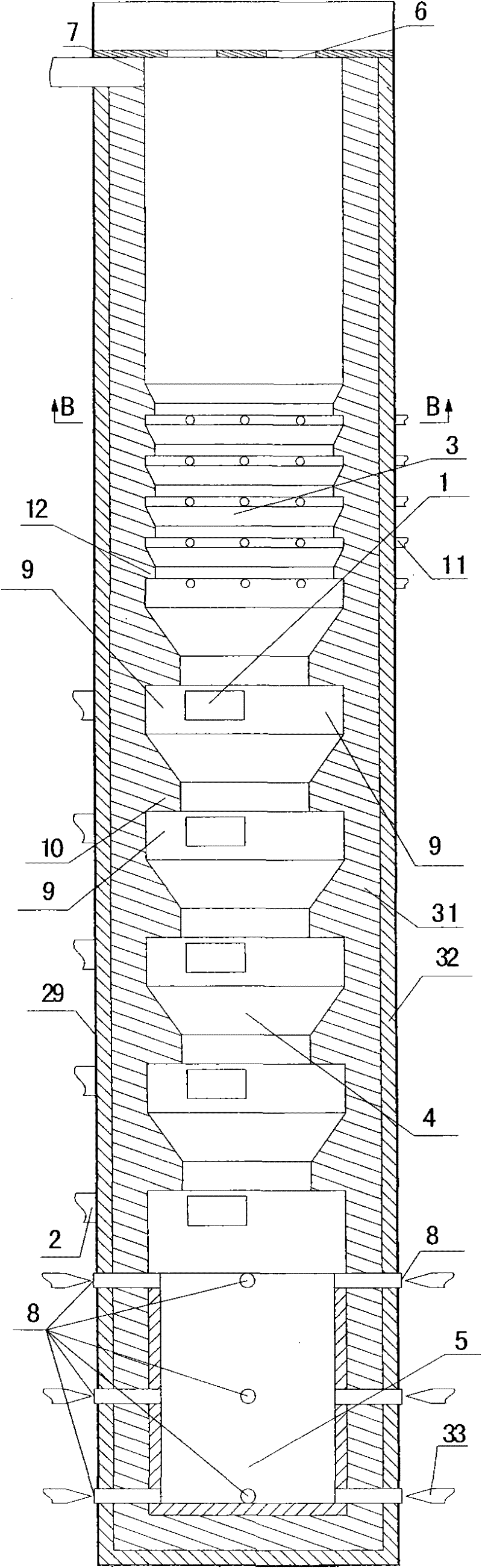

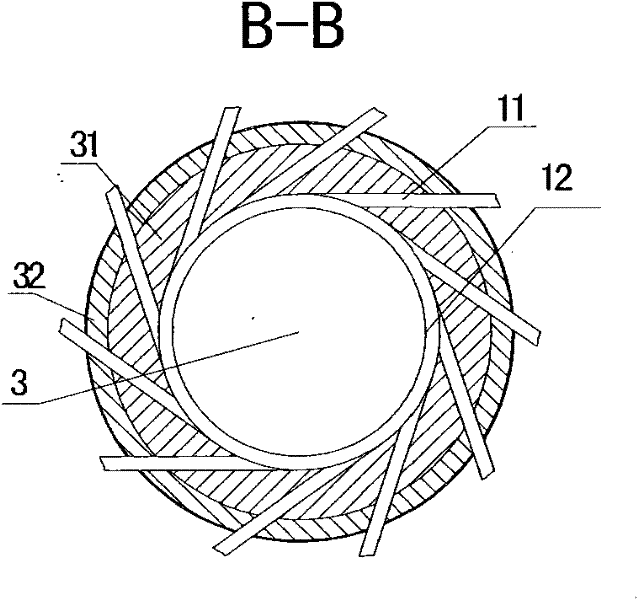

[0016] The main structure of the present invention is: a smelting furnace, comprising: a furnace chamber 29, a refractory material 31, an insulating material 32, a fan, a pipeline 30, an ignition device, a fuel supply device, and a discharge device 33, and at least one inlet is arranged on the side wall of the furnace chamber 29 The gas port 1 and the air inlet 1 are connected to at least one air intake passage 2, the air intake passage 2 is connected to the fan, and a plurality of fire passages 9 are arranged on the side wall of the furnace chamber, the air inlet 1 communicates with the fire passage 9, and the furnace chamber 29 is provided with a heating Chamber 3 and smelting chamber 4, the lower part of heating chamber 3 is connected to smelting chamber 4, the lower part of smelting chamber 4 is provided with hearth 5, the upper part of heating chamber 3 is provided with at least one heating chamber feed port 6, and the upper part of heating chamber 3 is provided with at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com