Flocculation-sterilization double-effect macromolecule and preparation method thereof

A polymer and flocculation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., to achieve the effects of strong neutralization ability, enhanced interaction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

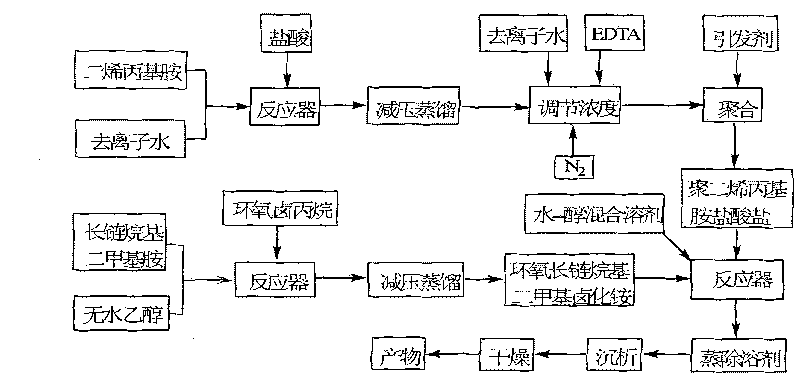

Method used

Image

Examples

Embodiment 1

[0046] (1) According to the volume ratio of deionized water and diallylamine is 0.3:1, first add 15mL of deionized water and 50mL of diallylamine into a 250mL reactor with mechanical stirring, and then slowly add 6.0 mol / L hydrochloric acid 67mL, control the temperature not higher than 30°C until the oil phase disappears;

[0047] (2) Distill under reduced pressure at -0.095MPa at 55°C until there is no obvious distillate to obtain a colorless or slightly reddish viscous transparent solution, collect the distillate for reuse;

[0048] (3) Add deionized water to adjust the mass fraction of diallylamine hydrochloride to 72.5% in the solution obtained by distillation in step (2), add 43mgEDTA, stir and dissolve to form a reaction solution, nitrogen gas to drive oxygen for 30min, and then Slowly add 7.5mL of a solution containing 375.8mg of ammonium persulfate dropwise at 55°C, react for 4 hours, add 1.6mL of a solution containing 81mg of ammonium persulfate, raise the temperature...

Embodiment 2

[0055] (1) According to the volume ratio of deionized water and diallylamine is 0.1:1, first add 5mL of deionized water and 50mL of diallylamine into a 250mL reactor with mechanical stirring, then slowly add 4.0 mol / L hydrochloric acid 101mL, control the temperature not higher than 30°C until the oil phase disappears;

[0056] (2) Distill under reduced pressure at -0.095MPa at 50°C until there is no obvious distillate to obtain a colorless or slightly reddish viscous transparent solution, collect the distillate for reuse;

[0057](3) Add deionized water to adjust the mass fraction of diallylamine hydrochloride to 70% in the solution obtained by distillation in step (2), add 5.3mgEDTA, stir and dissolve to form a reaction solution, nitrogen gas to drive oxygen for 30min, and then Slowly add 10 mL of a solution containing 478.5 mg of ammonium persulfate dropwise at 50°C, react for 5 hours, add 1 mL of a solution containing 53 mg of ammonium persulfate, raise the temperature to 6...

Embodiment 3

[0064] (1) According to the volume ratio of deionized water and diallylamine is 0.2:1, first add 10mL of deionized water and 50mL of diallylamine into a 250mL reactor with mechanical stirring, and then slowly drop 7.0 mol / L hydrochloric acid 57.5mL, control the temperature not higher than 30°C until the oil phase disappears;

[0065] (2) Distill under reduced pressure at -0.095MPa at 55°C until there is no obvious distillate to obtain a colorless or slightly reddish viscous transparent solution, collect the distillate for reuse;

[0066] (3) Add deionized water to adjust the mass fraction of diallylamine hydrochloride to 78.2% in the solution obtained by distillation in step (2), add 53.5mgEDTA, stir and dissolve to form a reaction solution, and nitrogen gas is used to drive oxygen for 30min, and then Slowly add 11 mL of a solution containing 534.4 mg of ammonium persulfate dropwise at 55°C, react for 3 hours, add 1.3 mL of a solution containing 64 mg of ammonium persulfate, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com