Method for separating saturated fatty acid methyl ester from biodiesel

A technology of fatty acid methyl ester and biodiesel, which is applied in chemical instruments and methods, biofuels, biomaterials, etc., can solve problems such as poor methanol solubility, and achieve the effects of optimizing dilution ratio, increasing processing capacity, and improving crystal morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

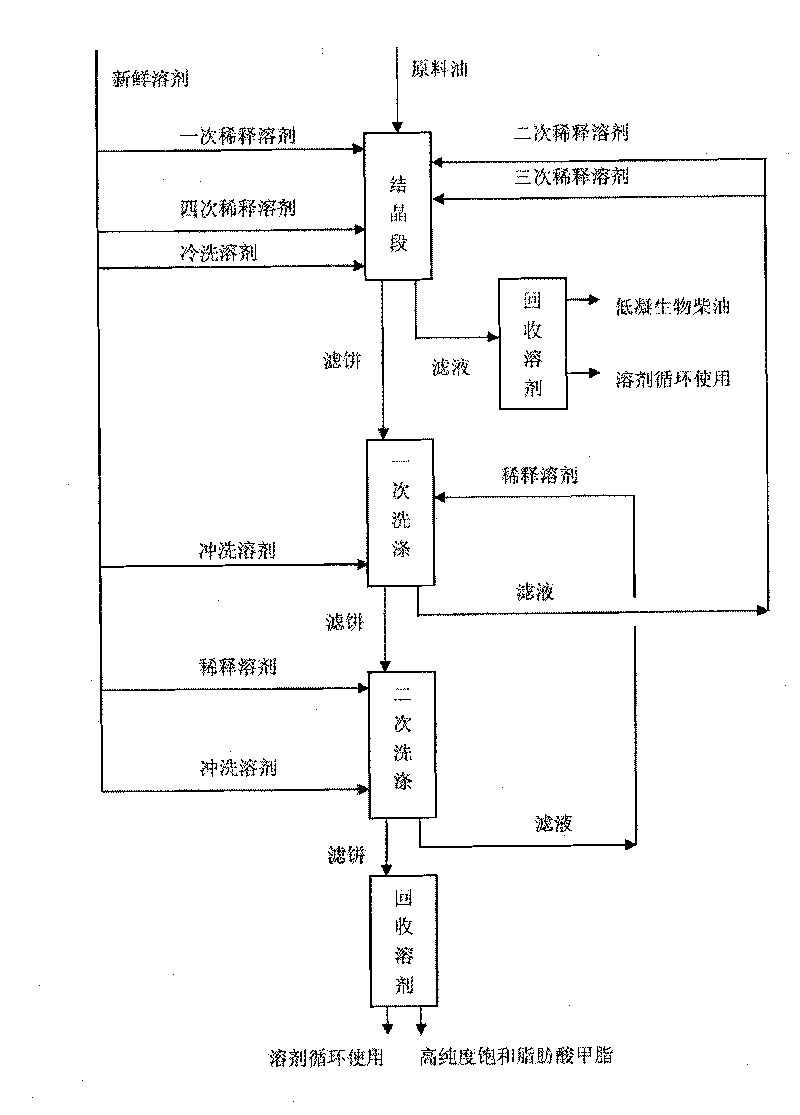

[0028] With the mixture of 5% (weight) acetone, 20% (weight) methyl ethyl ketone and 75% (weight) ethanol as solvent, add solvent to biodiesel in four times, one time and four times solvent use fresh solvent, two times and Use the filtrate from one filter cake washing for three solvents; the first dilution ratio is 0.2:1, the first dilution temperature is 45°C; the cooling rate is 1-2°C / min, the filtration temperature is -8°C, and the dilution solvent for the first filter cake washing is The filtrate of the secondary filter cake washing, the remaining test conditions and test results are shown in Table 2. The schematic flow chart is shown in Figure 1.

Embodiment 2

[0032] With the mixture of 15% (weight) acetone and 85% (weight) ethanol as solvent, the test process is basically the same as Example 1, except that the dilution ratio and operating temperature are different. The test conditions and test results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com