Self-cleaning sink of plastic extruder

A plastic extruder, self-cleaning technology, applied in the field of plastic production equipment, can solve the problems of changing technical solutions, undiscovered structure, water overflow in the tank, etc., to achieve the effect of improving cleaning quality, ensuring product quality, and stable water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

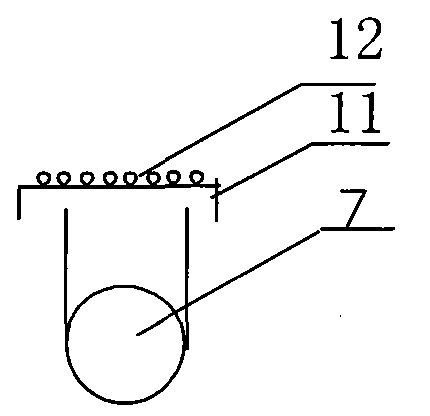

[0038] Plastic extruder self-cleaning sink (8), made of stainless steel, rectangular. One end of the lower part of the water tank (8) is provided with a water inlet pipe (4), and the water inlet pipe (4) is provided with a flat plate (9) and a mesh plate (10). The other end is provided with a water outlet pipe (7), the water outlet pipe (7) is provided with a filter screen cover (11), and the filter screen cover (11) is provided with a mesh plate (12). The upper part of the side of the water tank (8) is provided with a length of 10 cm and an overflow hole (6) of 5 cm in width, and the bottom of the side overflow hole (6) of the water tank (8) is provided with an overflow tank (1); (6) is positioned higher than the overflow tank (1); the bottom of the overflow tank (1) is provided with a water outlet (2). A miscellaneous plate (13) is arranged in the overflow tank, and a sponge (14) is arranged on the miscellaneous plate (13).

[0039] After the cooling water flows into the w...

Embodiment 2

[0043] Plastic extruder self-cleaning sink (8), made of stainless steel, round. The upper part of the circumference is provided with an overflow hole (6) with an arc length of 10 cm and a height of 5 cm. The outside of the garden-shaped tank (8) is provided with a circular overflow tank (1). All the other structures and operations are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com