Repaired mouth alloy melting granulating method and device for jewelries

A granulation device and filling technology, which is applied in the field of alloy melting furnaces, can solve the problems of affecting the melting and casting effect of jewelry products, particle size, uneven distribution of components, and unsuitability for industrialized mass production. It achieves moderate size, small surface oxidation, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

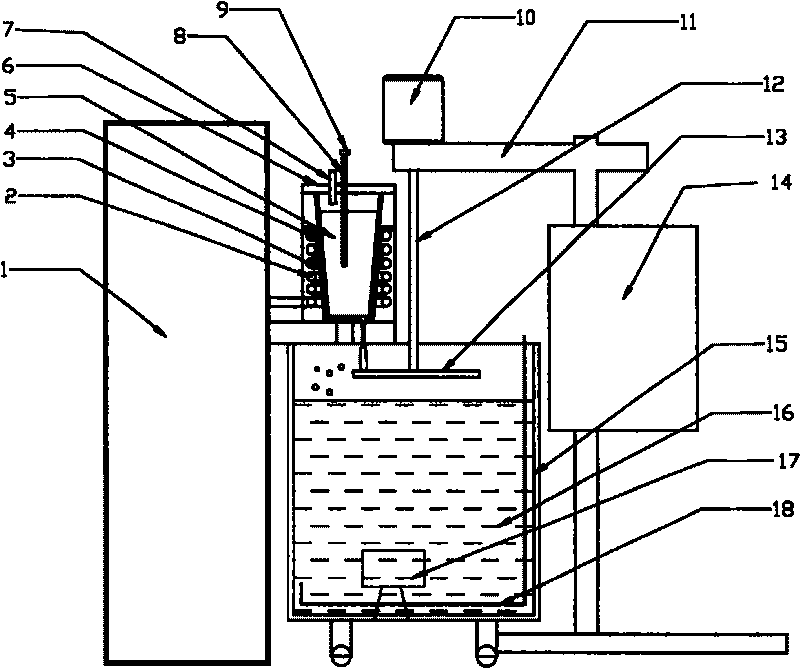

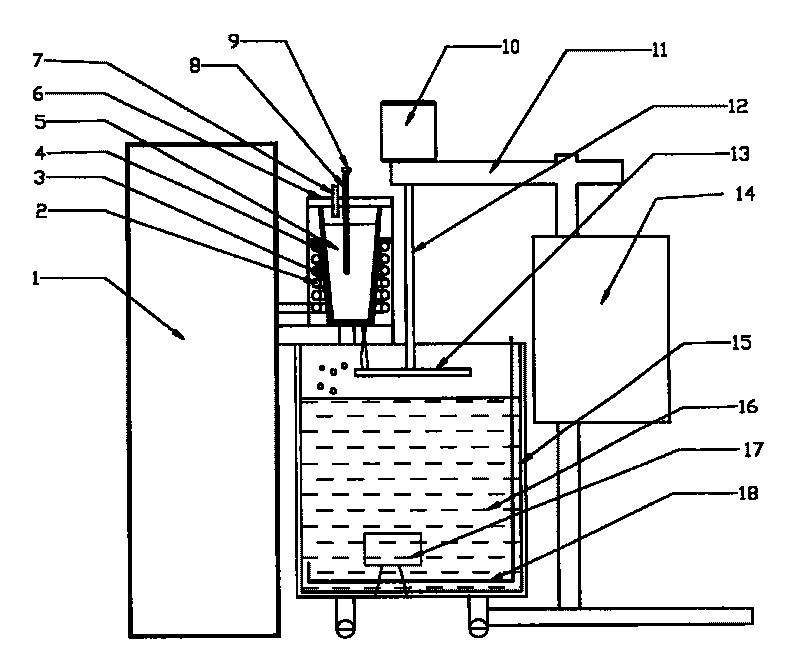

[0023] An embodiment of the method for smelting and granulating the jointing alloy for jewelry according to the present invention operates in the following manner.

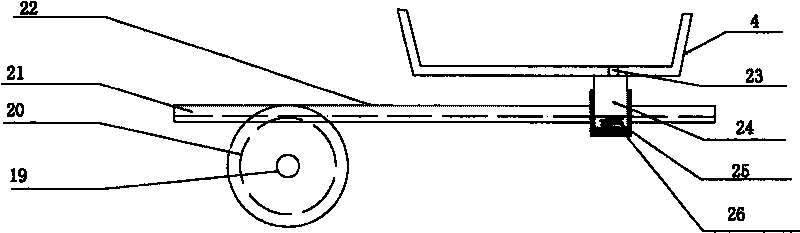

[0024] The smelting and granulation method of the jointing alloy for jewelry of the present invention is to make a bunch of molten alloy flowing out from the bottom of the crucible drop on a rotating horizontal graphite turntable, and after the liquid flow hits the turntable, it is drawn from the edge of the turntable by centrifugal force The droplets are formed by being thrown out, and these droplets move along the tangential direction of the turntable, and finally fall into the cooling water tank under the turntable to solidify into alloy particles. The joint alloy particles can be prepared simply and effectively by using this particle forming method. At the same time, according to different alloy materials and different particle size requirements, it can be conveniently obtained by adjusting the bottom aperture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com