Stone coal negative-pressure conveying system

A conveying system, pebble coal technology, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of conveying pipeline damage, easy sticking, reducing equipment reliability, etc., and achieve the effect of reducing pipeline wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

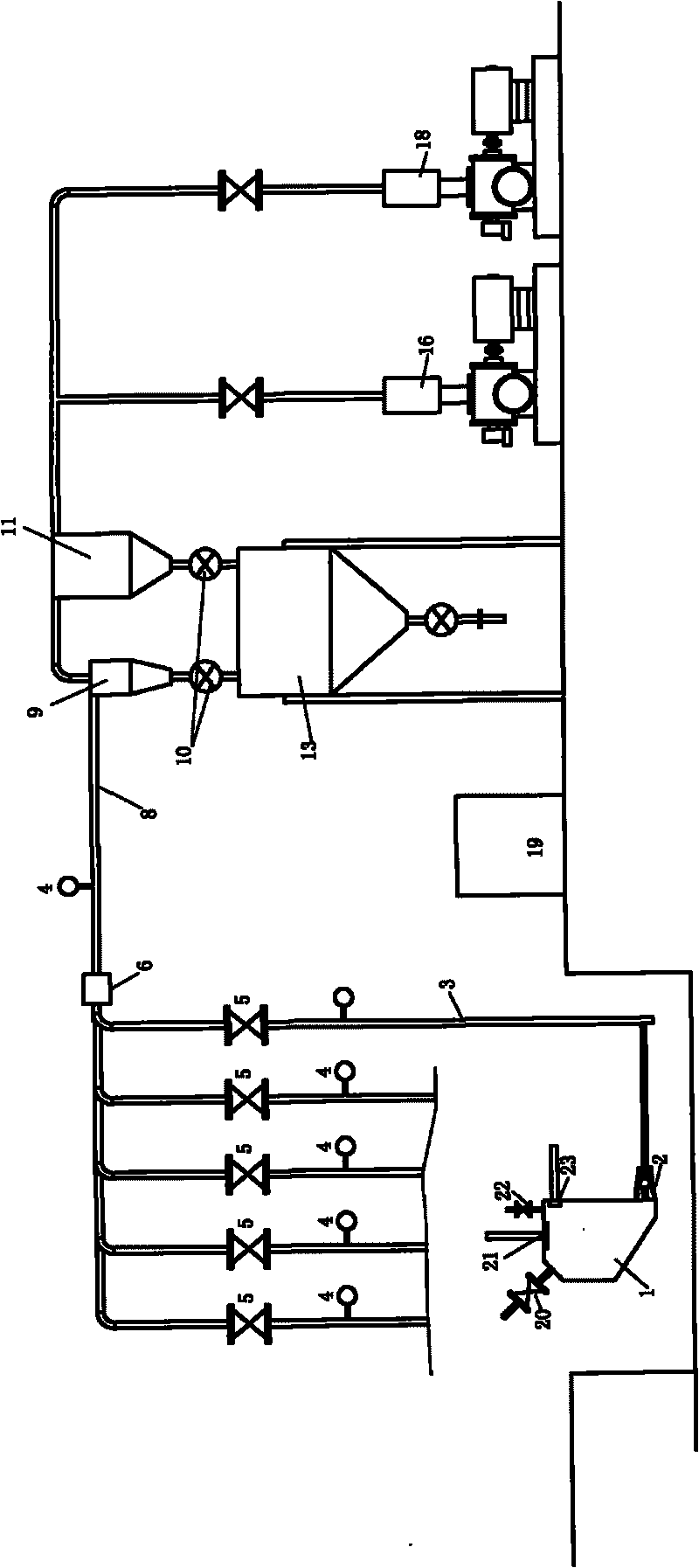

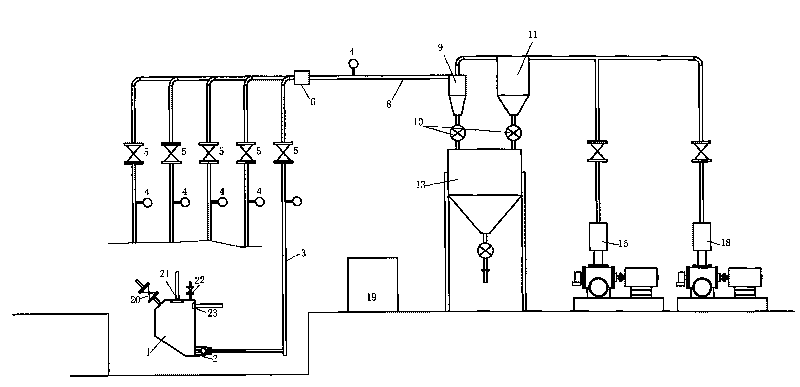

[0015] The symbols in the drawings include: 1-stone coal hopper; 2-suction nozzle; 3-branch pipe; 4-pressure transmitter; 5-switching valve; 10-air locker; 11-dust collector; 13-coal collection bin for gravel; 16-fan; 18-standby fan; 19-PLC control system; 20-feed valve; 21-spray device; 22-inlet Air valve; 23-temperature measuring device.

[0016] Embodiments of the present invention are as follows:

[0017] Such as figure 1 As shown, the pebble coal negative pressure pneumatic conveying system is provided with five pebble coal hoppers 1, and the upper part of these pebble coal hoppers 1 is equipped with a feed valve 20, a spray device 21, an air inlet valve 22 and a temperature measuring device 23, and through the switching valve 5. The branch pipe 3 is connected to the confluence bin 6; the confluence bin 6 is connected to the upper part of the cyclone separator 9 through the negative pressure main pipe 8; It is connected with the gravel coal collection bin 13; the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com