CPLD-based multi-subdivision high-speed constant-torque controller of two-phase hybrid stepping motor

A stepper motor and hybrid technology, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of shortening hardware design and upgrading, waste, and insufficient utilization of resources, so as to save resources, Simple structure and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

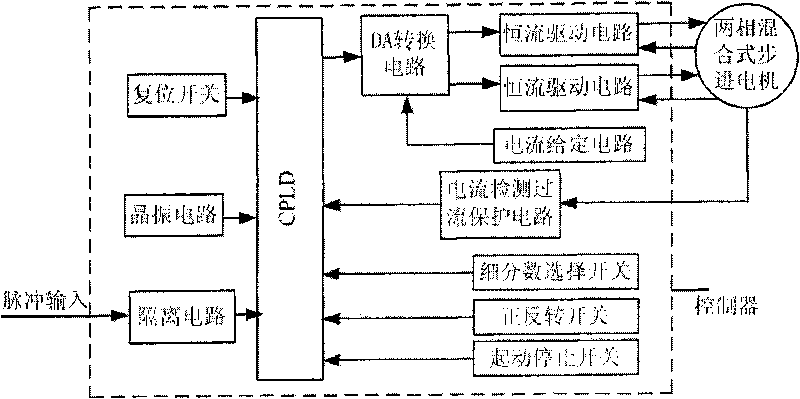

[0014] see figure 1 , as shown in the embodiment, the CPLD-based two-phase hybrid stepper motor multi-subdivision high-speed constant torque control system includes pulse input, controller and two-phase hybrid stepper motor. The controller includes: a reset switch, crystal oscillator circuit, pulse input isolation circuit, three subdivision selection switches, a forward and reverse switch, a start and stop switch, CPLD main control chip, DA conversion circuit, current detection overcurrent protection circuit , Current given circuit, constant current drive circuit.

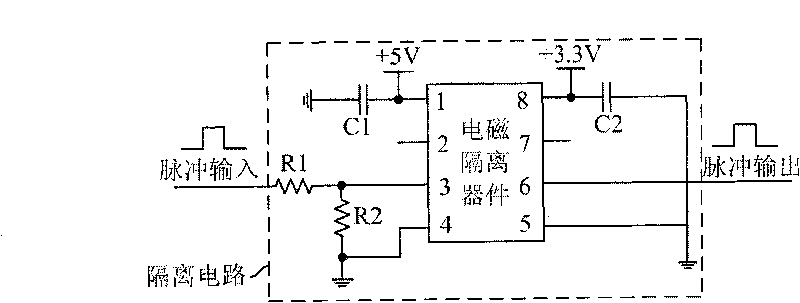

[0015] The isolation circuit adopts the chip ADUM1200, the CPLD main control chip adopts EPM570T100C3, the DA conversion circuit adopts the NJU39610D2DA conversion chip, and the constant current drive circuit adopts the driver chip LMD18245T.

[0016] The circuit connection relationship is: the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com