Method for improving process window of self-aligned cell module in SONOS technology

A process window and self-alignment technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of improving the process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

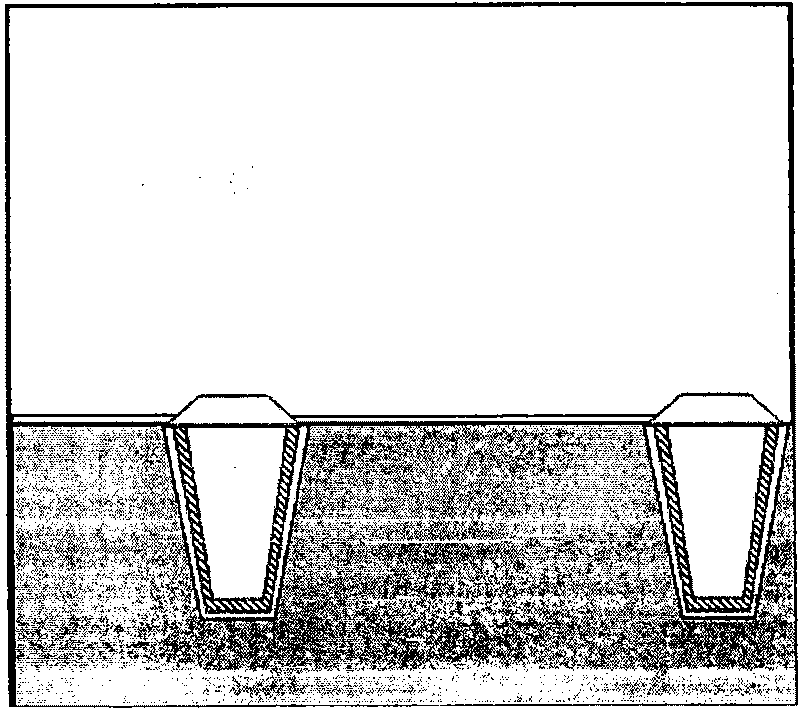

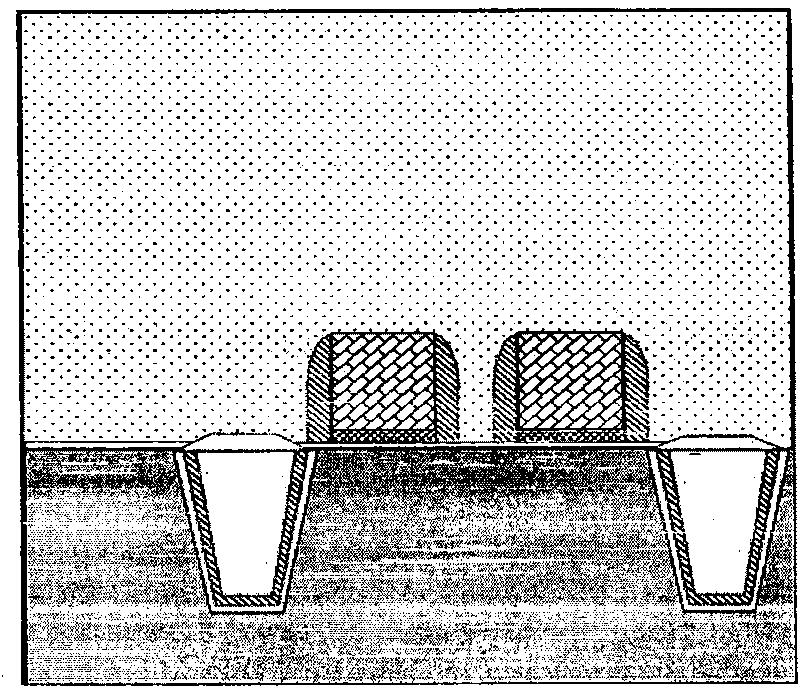

[0013] The core step of the present invention is to adopt undoped oxide film as the pre-metal dielectric interlayer film medium, adopt phosphoric acid glass as field isolation medium, introduce oxide film and nitride film to eliminate the influence of P element diffusion in phosphoric acid glass on the device At the same time, the use of a special etching process makes it possible to have a high selectivity ratio of undoped oxide film to shallow trench isolation STI phosphoric acid glass when etching self-aligned holes. In this way, a series of process difficulties caused by the flower pattern introduced when phosphate glass is used as the pre-metal dielectric interlayer film medium can be avoided, thereby greatly improving the process window of the entire module.

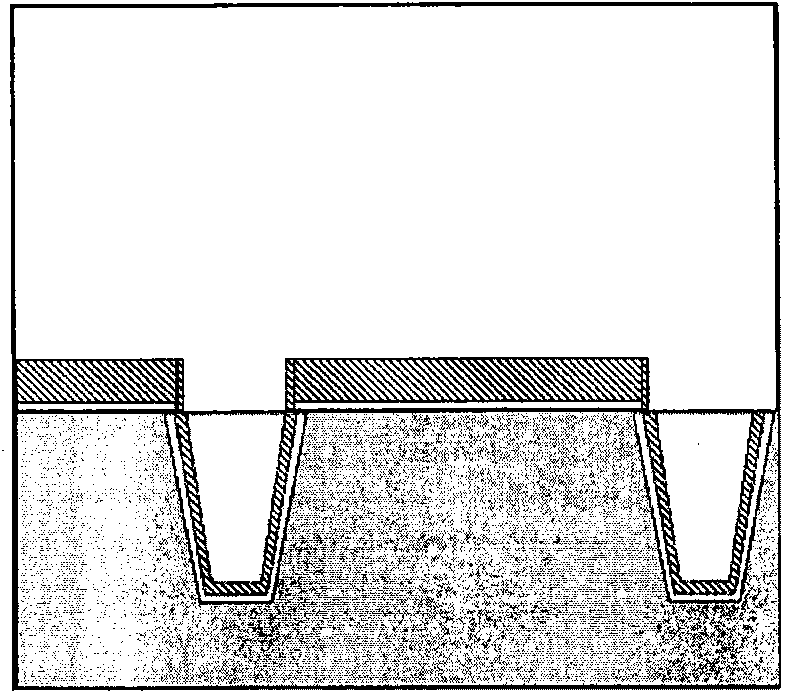

[0014] The main process flow of the present invention (film layer structure and dry etching process) includes: the first step, after the first layer of oxide film is grown in the traditional shallow trench isolation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com