Device for testing low-temperature heat conduction rate of foam heat insulation material in loaded state

A technology of thermal insulation materials and testing devices, which is applied in the direction of material thermal development, etc., can solve the problems of low-temperature thermal conductivity testing of non-foam thermal insulation materials, etc., and achieve the effects of reducing test costs, eliminating heat loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

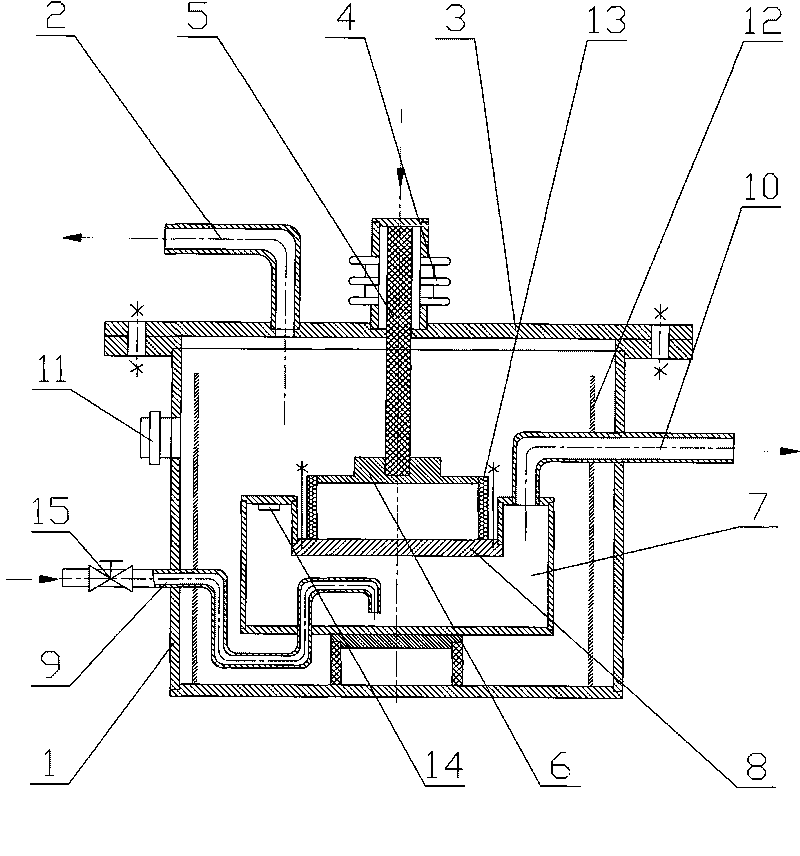

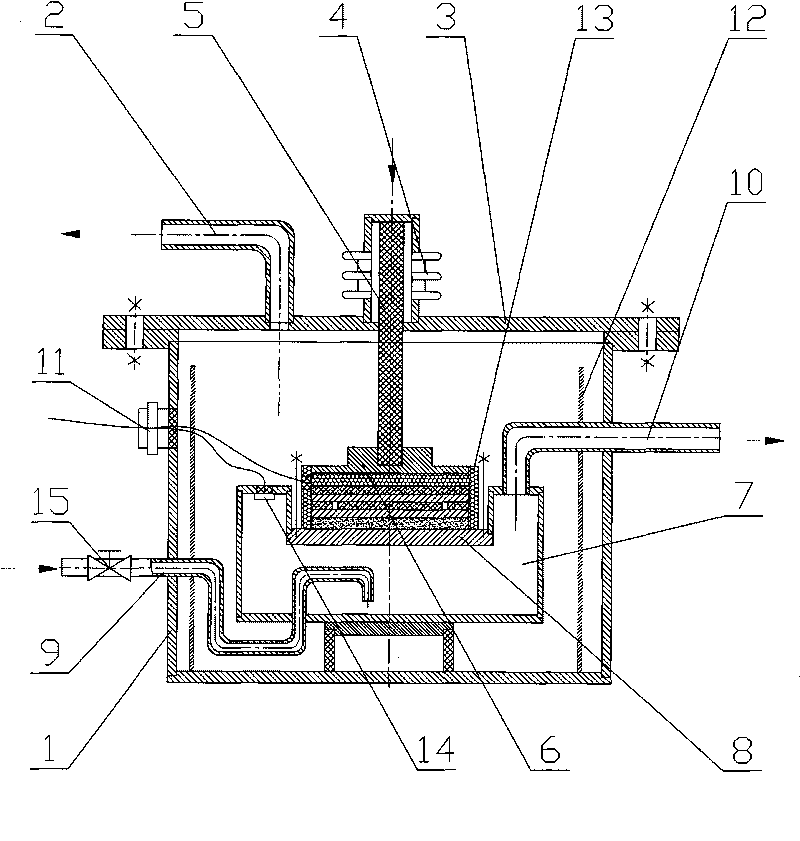

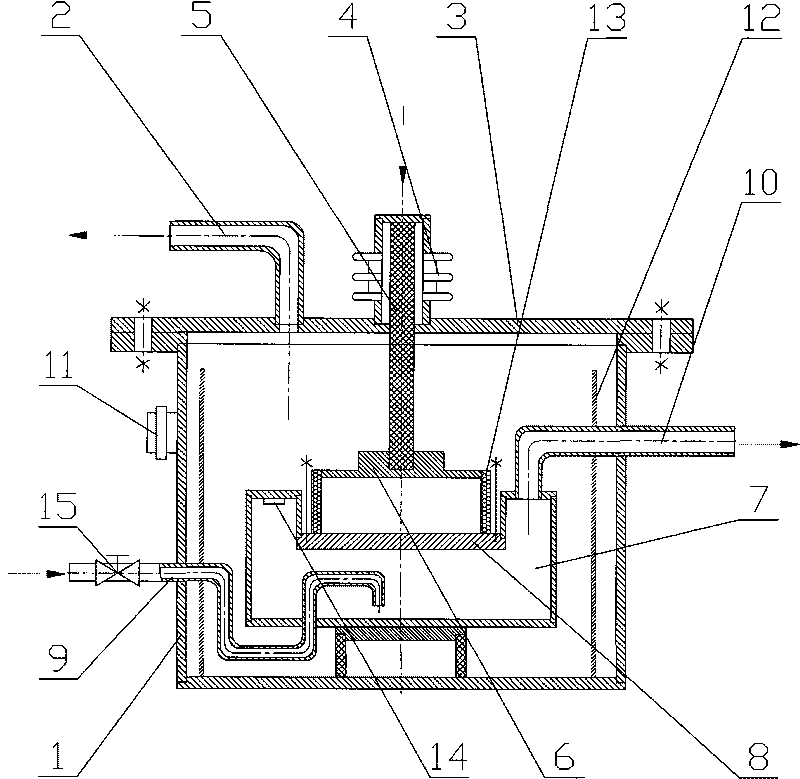

[0019] The specific embodiments of the present invention will be described below in conjunction with the drawings. Such as figure 1 Shown: there is a sealed vacuum chamber 1, and the entire inner and outer surfaces of the vacuum chamber 1 can be polished to function as a heat radiation shield. The vacuum chamber is provided with a wire hole 11 and the vacuum chamber The vacuum tube 2 is communicated in the body 1, and a bellows 4 is welded to the cover (flange) 3 on the vacuum chamber 1. The bellows 4 is built with a heat-insulating pressure rod 5 made of glass fiber reinforced plastic and other heat-insulating materials. The upper end of the pressure rod 5 is connected with the bellows 4, and the lower end is inserted into the vacuum chamber 1 through the cover 3 and connected with the pressure plate 6. A cold chamber 7 is provided under the pressure plate 6, and the upper surface of the cold chamber 7 is a cold plate 8. The lower end of the cold chamber 7 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com