Thermal plasma device for incinerating marine garbage

A technology of thermal plasma and plasma generator, applied in the direction of plasma, incinerator, combustion method, etc., can solve the problems of slow heat conduction, poor mobility of equipment operation, low efficiency, etc., to improve combustion efficiency, prolong residence time, heat Good transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

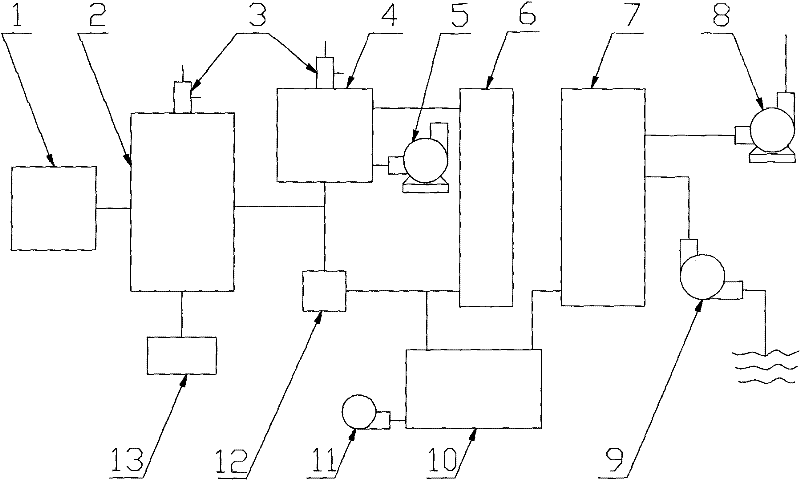

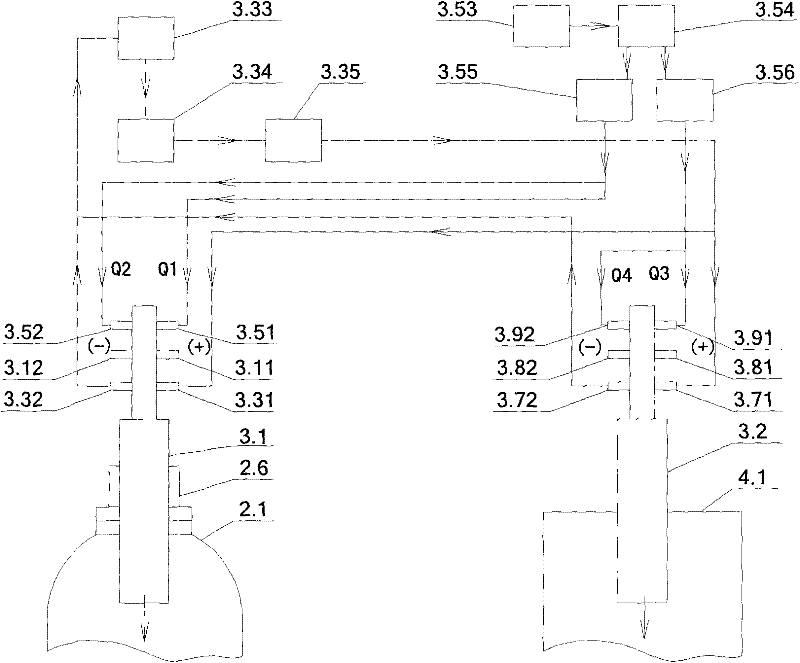

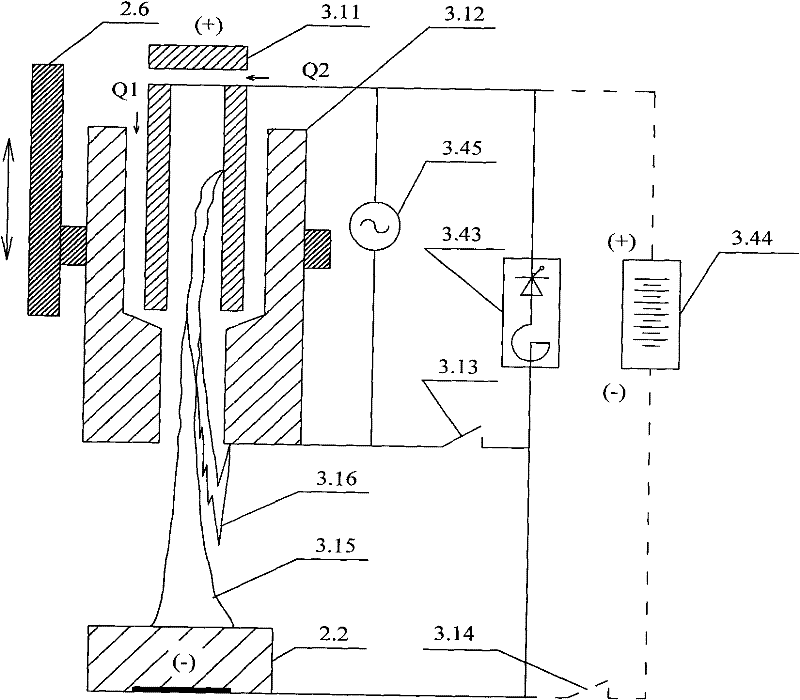

[0047] A thermal plasma incineration device for ship garbage, the overall structure is as follows figure 1 As shown, it includes a feed system 1, an incineration system (including an incinerator 2, a plasma generation system 3 and a second combustion chamber 4), a blower 5, a heat exchanger 6, a desulfurization and dust removal tower 7, an induced draft fan 8, a first water pump 9, Quench cooler 10, second water pump 11, slag extractor 13 and automatic control system. The feeding system is connected to the incineration system through pipelines, and plays the role of temporarily storing garbage and transporting garbage to the incineration system.

[0048] Described below:

[0049] 1. The structure of the feeding system is as follows: F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com