Low-noise structural oilless air compressor

An air compressor and low-noise technology, which is applied to mechanical equipment, machines/engines, and liquid-variable machinery, etc., can solve problems such as volume reduction, strong mechanical impact, and unsatisfactory noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

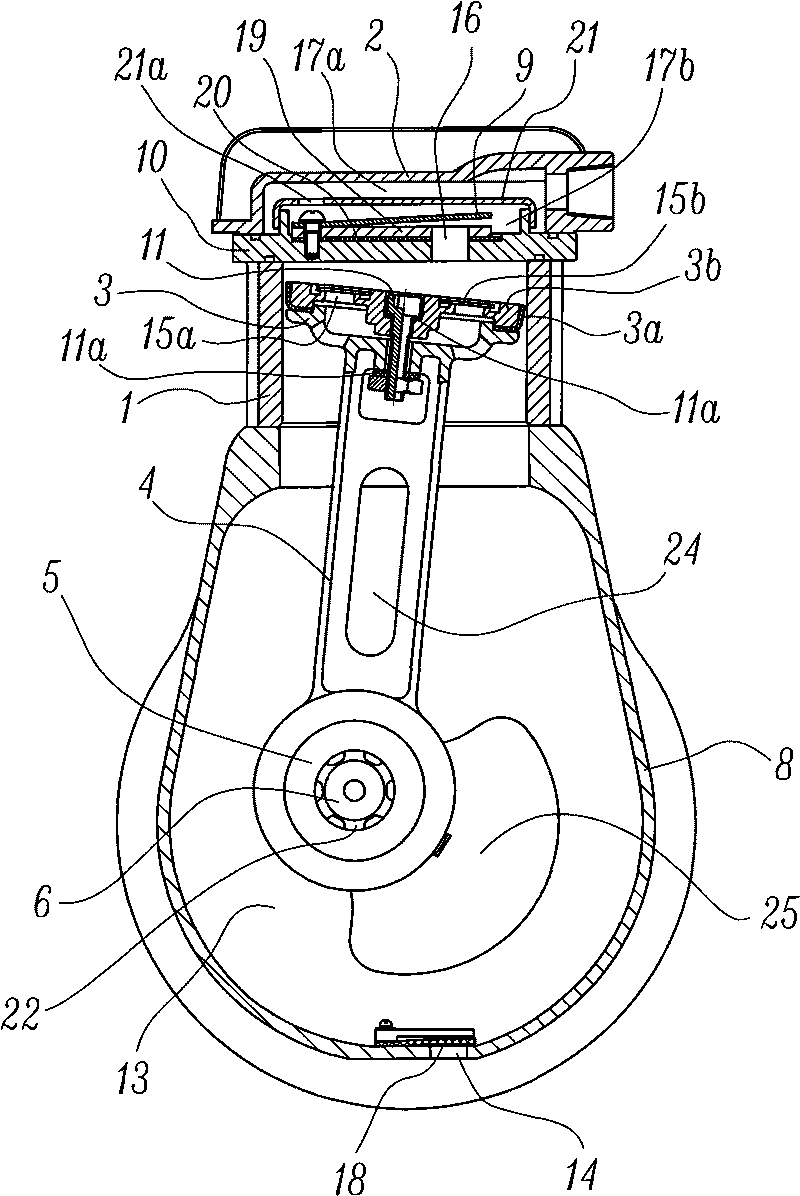

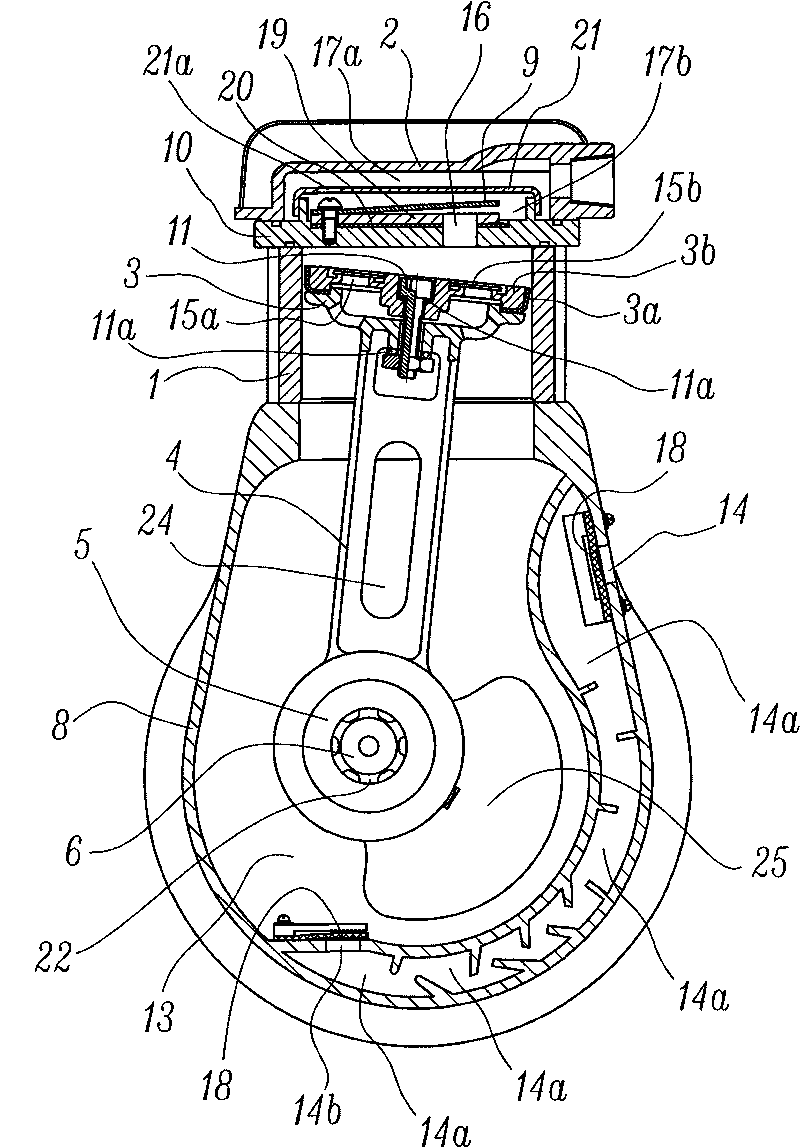

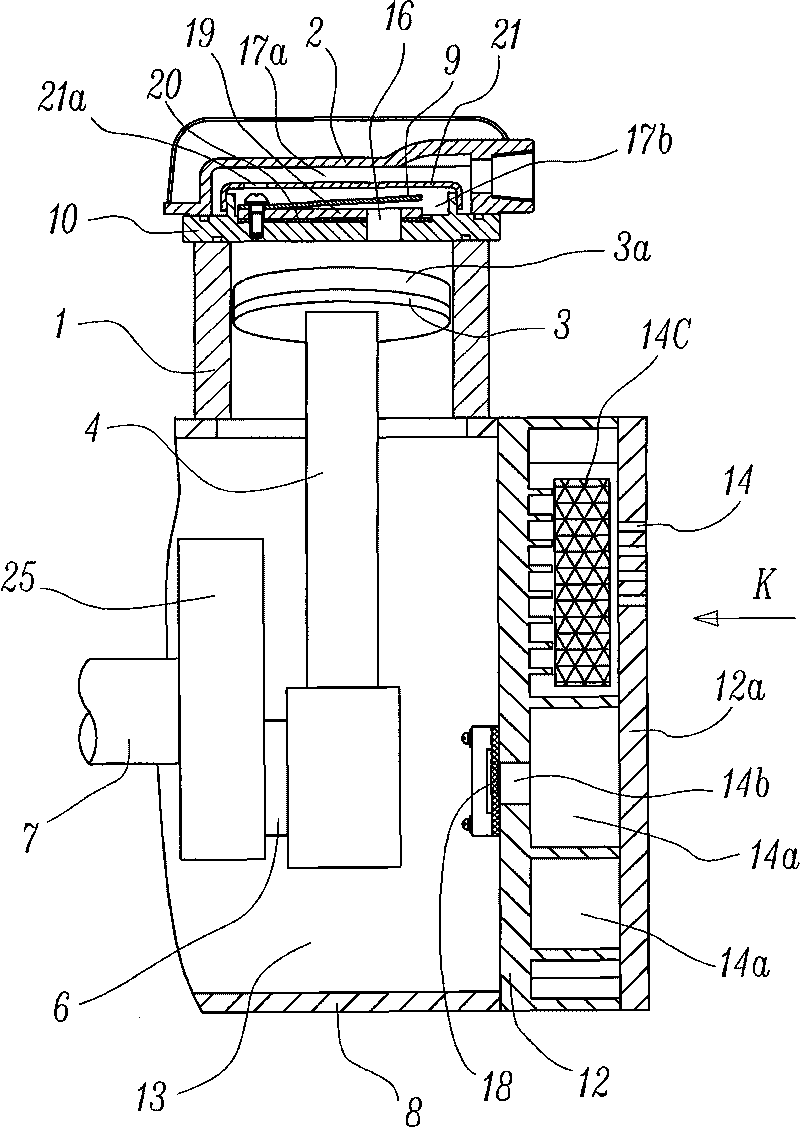

[0020] The present invention will be further described below with specific embodiment: see Figure 1-5 :

[0021] Oil-free air compressor with low noise structure, including: cylinder 1, cylinder head 2, piston 3, connecting rod 4, connecting rod big end bearing 5, crank pin 6, crankshaft 7, crankcase 8, exhaust valve plate 9 and valve seat 10, wherein the piston 3 is equipped with a sealing ring or sealing cup 3a made of self-lubricating material, and the sealing ring or sealing cup 3a can be fastened to the bottom of the piston 3 through the fastening screw 11 and the piston cover plate 3b The main body (as shown in the figure) can also be directly fitted on the ring groove of the piston 3 (not shown in the figure), and the sealing ring or sealing cup 3a is in sealing cooperation with the cylinder bore of the cylinder 1 (allowing the existence of manufacturing errors, assembly errors, and gap leakage caused by rocking motion), the small end of the connecting rod 4 is tightl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com