Method for producing acetylene derivative and methanol through coal plasma pyrolysis

A plasma cracking and plasma technology, which is applied in the field of plasma cracking coal to produce acetylene downstream products and methanol, can solve the problems of low coal comprehensive efficiency, low comprehensive utilization rate, poor economic benefits, etc., to reduce investment and reduce investment risk , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

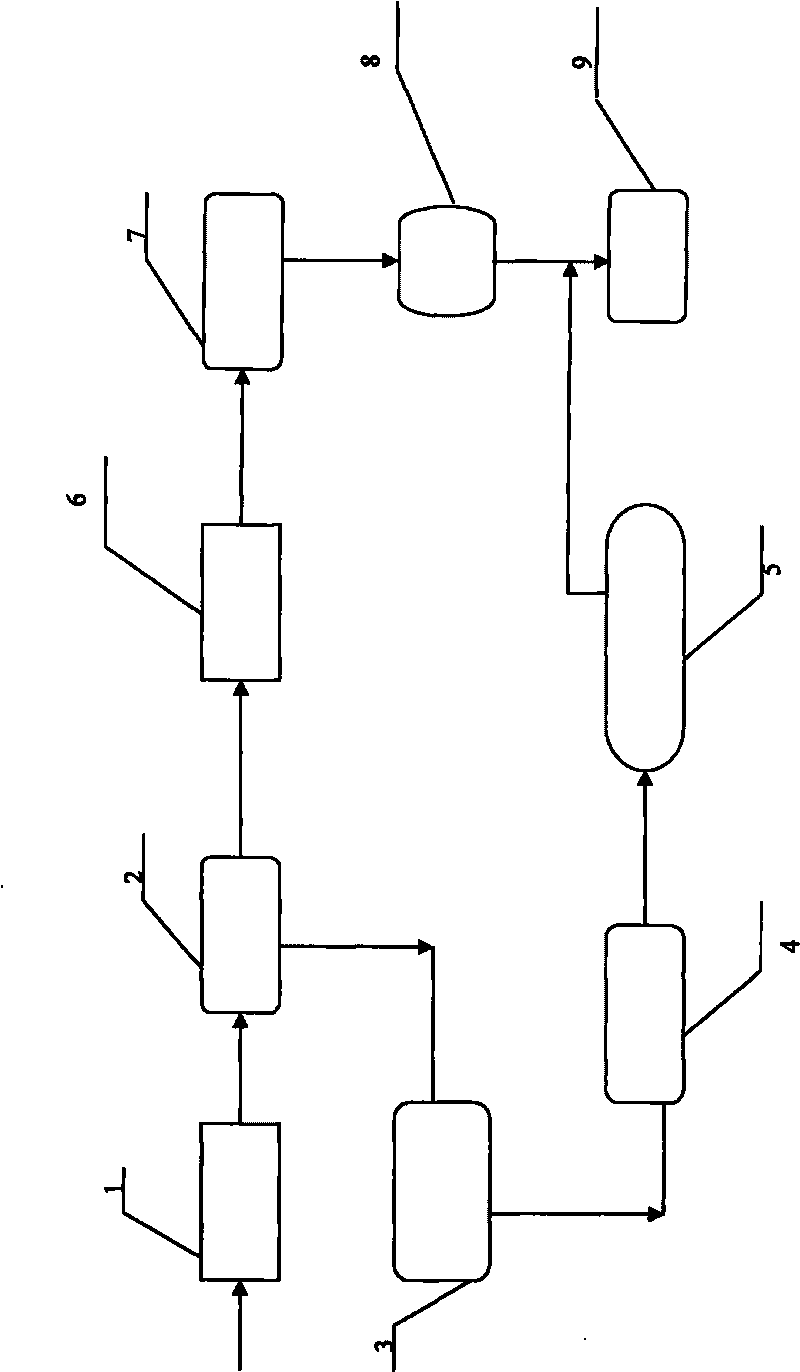

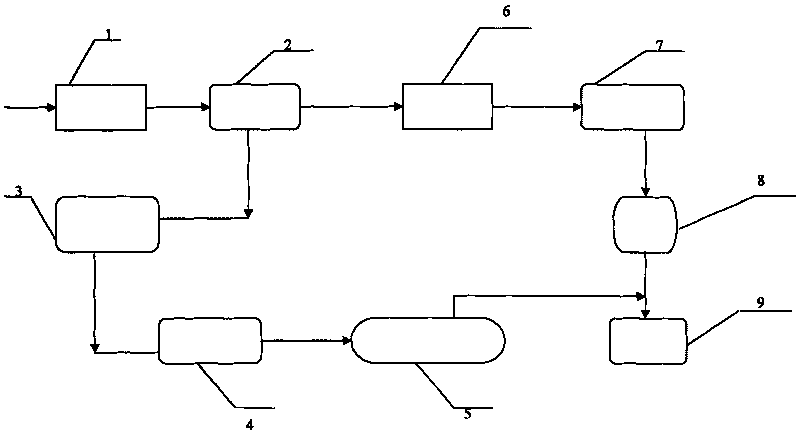

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] refer to figure 1 , the present embodiment 1 comprises the steps of the following order: plasma cracking coal section 1, gas-solid-liquid separation section 2, pyrolysis gas purification section 3, cracking gas separation section 4, acetylene downstream derivative section 5, coal-water slurry pretreatment section 6 , water gas generation section 7, coal gas purification treatment section 8, methanol synthesis section 9; from the three-phase mixture of plasma cracking coal section 1, the three-phase separation in gas-solid-liquid separation section 2 obtains cracked gas, and the cracked gas is in the cracked gas purification section In 3, the ash, hydrogen cyanide, hydrogen sulfide, carbon dioxide, benzene, tar and moisture contained in the cracked gas are removed, and the components of the cracked gas after the purification section are hydrogen, argon, acetyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com