Fireproof and waterproof coating for tunnel

A technology of waterproof coating, tunnel, applied in the field of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

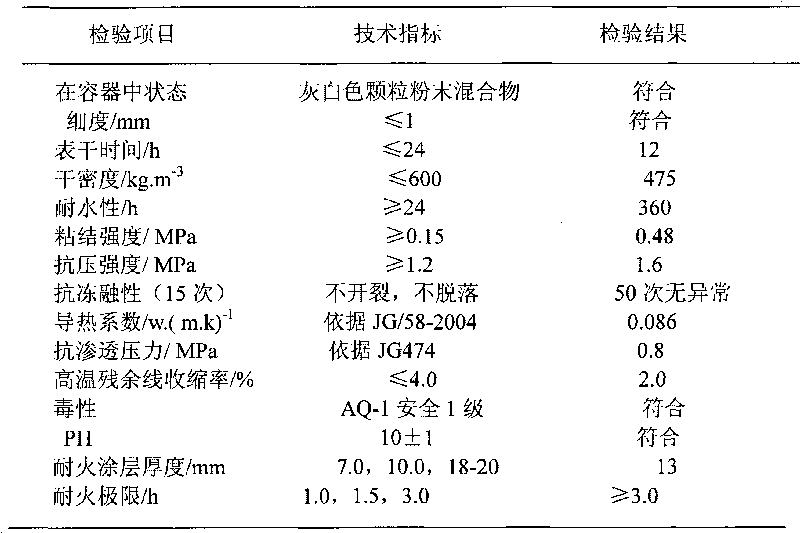

Image

Examples

Embodiment

[0024] A fire-proof and waterproof coating for tunnels, which is characterized in that it is composed of composite binder, fire-resistant and heat-insulating material, expansion foam material, and flame-retardant and smoke-eliminating material. The components of the formula are as follows;

[0025] Composite binder 45%

[0026] Refractory insulation 40%

[0027] Expanded foam material 8%

[0028] Flame retardant and smoke suppressing material 7%

[0029] The proportions of the above components and ingredients are all calculated by weight percentage.

[0030] The composite binder is composed of 30% high alumina cement CA-50, 6% silica fume, 2% redispersible rubber powder RI551Z, 0.3% hydroxypropyl methylcellulose, and 9% osmotic crystalline active masterbatch, of which the active The masterbatch consists of 25% instant sodium silicate powder, 45% lime calcium powder, 25% aluminum hardate, 4.4% naphthalene-based water reducer, 0.15% air-entraining agent, 0.15% active agent, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com