Microwave method for peeling laminar inorganic material quickly

A technology of inorganic materials and inorganic material layers, applied in the direction of inorganic chemistry, chemical instruments and methods, silicon compounds, etc., can solve the problems of weakened bonding force, long time required, and damage to crystal structure, etc. Short, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Preparation of kaolin-hydrazine intercalation complex

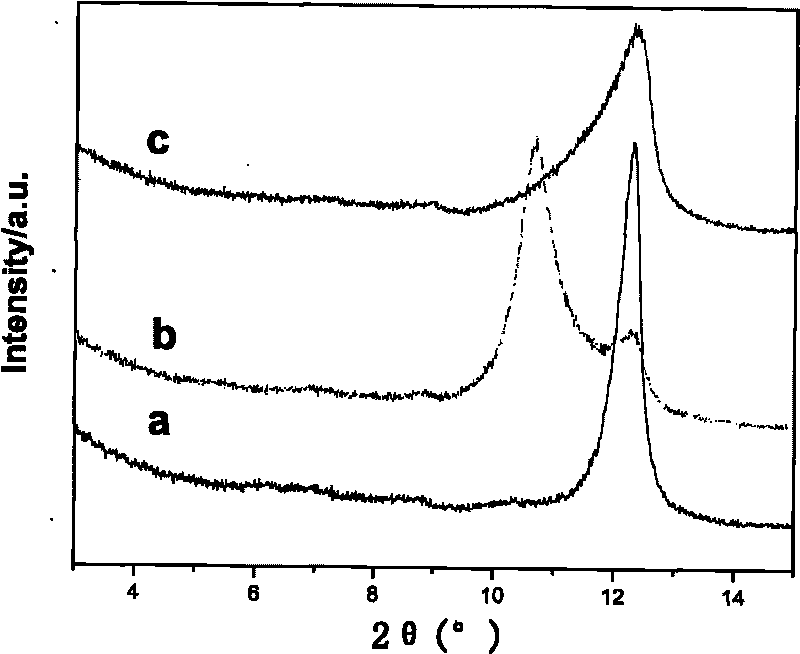

[0026] Weigh 5g of kaolin, put it in a flask, then add 30ml of hydrazine hydrate solution (concentration is about 80%), stir at room temperature for 24h, remove excess solution after centrifugation, and dry under vacuum at 60°C to obtain kaolin-hydrazine The intercalation complex has an intercalation rate of 82.7%.

[0027] The second step: rapid peeling of kaolin by microwave method

[0028] Put 1 g of the solid kaolin-hydrazine intercalation complex prepared above into a plastic beaker, place it in a household microwave oven for 5 minutes, and then take it out, so that the kaolin can be naturally peeled off.

[0029] Step Three: Finished Product

[0030] The exfoliation product obtained above was analyzed and measured, and it was found that the grain thickness decreased from 30nm to 8.6nm, and the total weight loss also increased from 11.8% to 13.4% of the original kaolin clay.

Embodiment 2

[0032] Step 1: Preparation of hydrotalcite-formamide intercalation complex

[0033] (1) A certain amount of NaOH, NaCO 3 Alkaline solution and MgSO with a mass ratio of 2:1 4 , Al(NO 3 ) 3 9H 2 The salt solution of O rapidly nucleates in the rotating liquid film at room temperature, crystallizes the obtained slurry at 100°C for 6h, centrifuges, washes the filter cake until pH<8, and dries at 70°C for 24h to obtain magnesium aluminum hydrotalcite.

[0034] (2) Take 0.4 g of magnesium aluminum hydrotalcite and a certain concentration of formamide solution in a three-necked flask, reflux and stir at 60 ° C for 10 h under the protection of nitrogen atmosphere, filter and wash, and vacuum dry at 50 ° C for 3 h to obtain the desired sample. It is the hydrotalcite-formamide intercalation complex.

[0035] Step 2: Quickly peel off the hydrotalcite

[0036] Put 1 g of the hydrotalcite-acetic acid intercalation compound prepared above into a microwave oven to heat, so that the hyd...

Embodiment 3

[0040] Step 1: Preparation of montmorillonite-urea intercalation complex

[0041] Weigh 20g of urea to make 30ml solution, weigh 5g of montmorillonite, put them together in a flask, stir at 85°C for 24h, remove excess solution after centrifugation, wash the obtained sample with deionized water, and dry at 60°C , that is, the montmorillonite-urea intercalation complex is obtained, and the intercalation rate is 35%.

[0042] The second step: rapid peeling of montmorillonite by microwave method

[0043] Put 1 g of the solid montmorillonite-urea intercalation complex prepared above into a plastic beaker, place it in a household microwave oven for 5 minutes, and then take it out, so that the montmorillonite can be naturally peeled off.

[0044] Step 3: Finished Product

[0045] The peeling product obtained above was analyzed and measured, and it was found that the thickness of its crystal grains decreased by about ten nanometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com