Method for preparing silicon dioxide hybridized quantum dot by using one-pot method

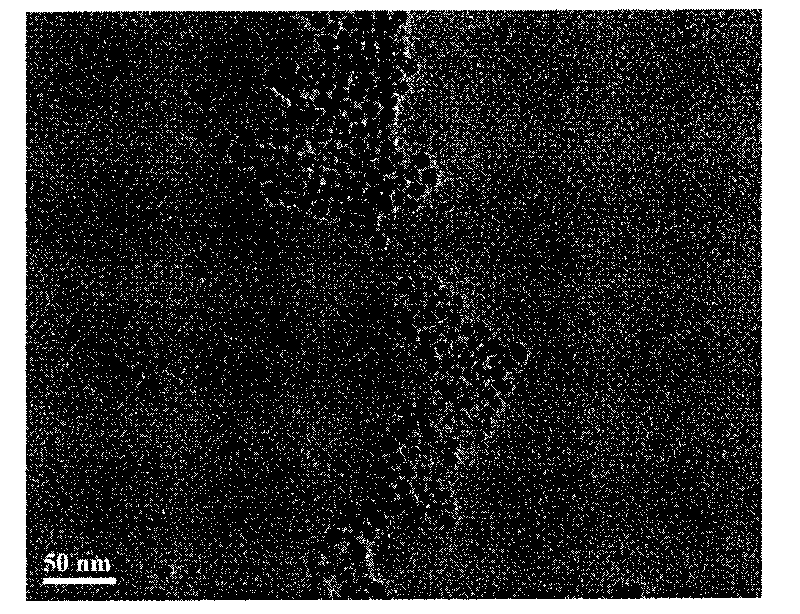

A technology of silicon dioxide and quantum dots, which is applied in the field of nanotechnology preparation, can solve the problems of difficult wide application of quantum dots, unstable luminescence, and difficult preparation, and achieve good application prospects, excellent luminescent performance, and low toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

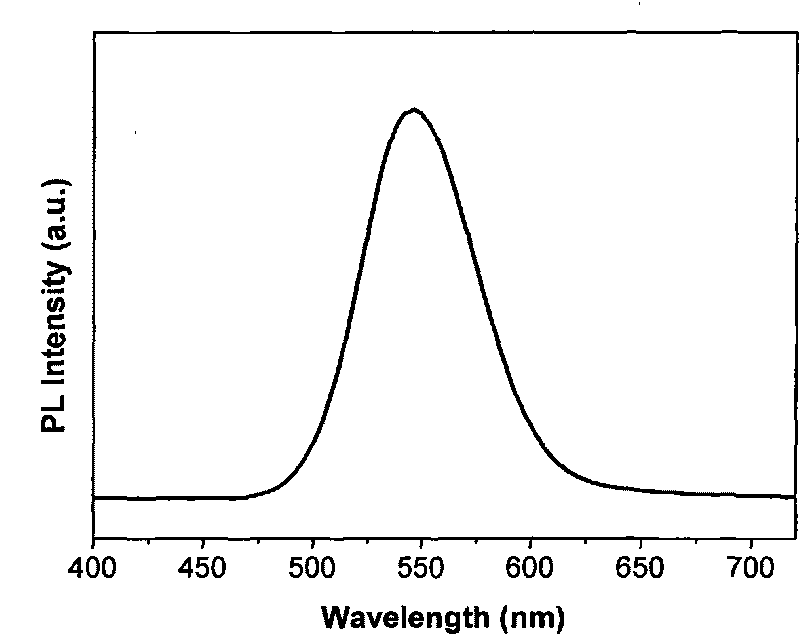

[0016] Using cadmium acetate as the metal source for the preparation of quantum dots, mercaptopropionic acid stabilizer, sodium selenium hydride as the non-metallic source for the preparation of quantum dots, and ethyl orthosilicate as the source of silicon dioxide, the preparation of silicon dioxide hybrid CdSe quantum dots .

[0017] Step (a): In a 2-liter reaction flask, add 1.33 grams of cadmium acetate and 2.55 grams of mercaptopropionic acid into 1.5 liters of deionized water, and adjust the pH of the solution to 8.0 with sodium hydroxide to prepare a cadmium ion precursor solution.

[0018] Step (b): The temperature of the solution is raised to 100° C. while passing nitrogen into the reaction bottle, and then 4 ml of an aqueous solution containing 0.41 g of sodium selenium hydride is added to prepare a precursor liquid of CdSe quantum dots.

[0019] Step (c): Inject 20.8 g of ethyl orthosilicate into the precursor liquid of CdSe quantum dots, and react at 100° C. for 48...

Embodiment 2

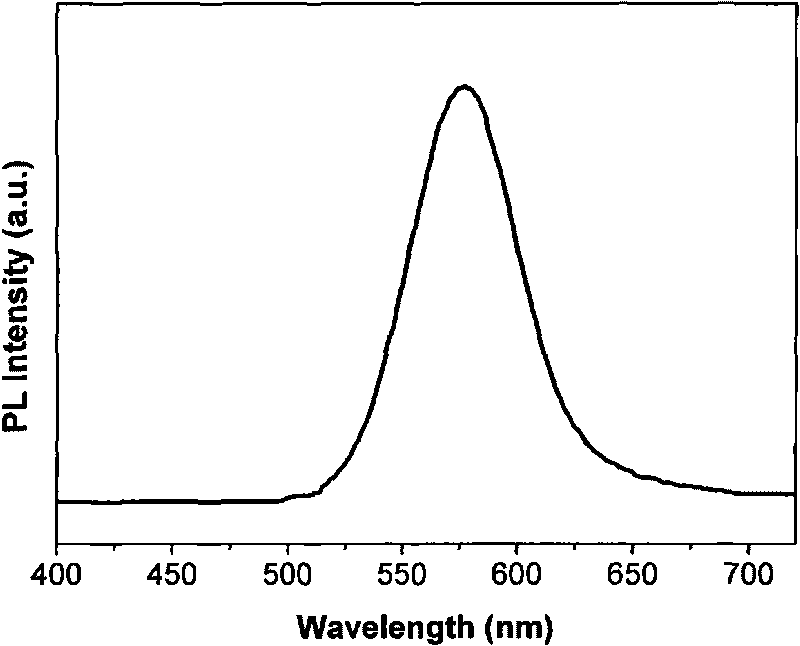

[0021] Using cadmium acetate as the metal source for the preparation of quantum dots, mercaptopropionic acid stabilizer, potassium selenium hydride as the non-metallic source for the preparation of quantum dots, and ethyl orthosilicate as the source of silicon dioxide, the preparation of silicon dioxide hybrid CdSe quantum dots .

[0022] Step (a): In a 2-liter reaction flask, add 0.27 g of cadmium acetate and 0.65 g of mercaptopropionic acid into 1.5 liters of deionized water, and adjust the pH value of the solution to 10.0 with sodium hydroxide to prepare a cadmium ion precursor solution.

[0023] Step (b): The temperature of the solution was raised to 90° C. while passing nitrogen into the reaction flask, and then 4 ml of an aqueous solution containing 0.1 g of potassium selenide was added to prepare a precursor liquid of CdSe quantum dots.

[0024] Step (c): Inject 20.8 g of ethyl orthosilicate into the precursor liquid of CdSe quantum dots, and react at 90° C. for 72 hour...

Embodiment 3

[0026] Using cadmium acetate as the metal source for preparing quantum dots, thioglycolic acid stabilizer, sodium selenium hydride as the non-metallic source for preparing quantum dots, and ethyl orthosilicate as the silicon dioxide source, the silicon dioxide hybrid CdSe quantum dots were prepared.

[0027] Step (a): In a 2-liter reaction flask, add 4.1 grams of cadmium acetate and 4.4 grams of mercaptoacetic acid into 1.5 liters of deionized water, and adjust the pH value of the solution to 7.5 with sodium hydroxide to prepare a cadmium ion precursor solution.

[0028] Step (b): The temperature of the solution is raised to 100° C. while passing nitrogen into the reaction flask, and then 4 ml of an aqueous solution containing 0.96 g of sodium selenium hydride is added to prepare a precursor liquid of CdSe quantum dots.

[0029] Step (c): Inject 150 grams of tetraethyl orthosilicate into the precursor liquid of CdSe quantum dots, and react at 100° C. for 24 hours to prepare sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com