Meat food processing device

A processing device, meat food technology, applied in the direction of meat processing equipment, processed fish, processed meat, etc., can solve the problems of small drying space, difficult production, complex structure, etc., to achieve easy production, avoid electromagnetic interference, and expand drying effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

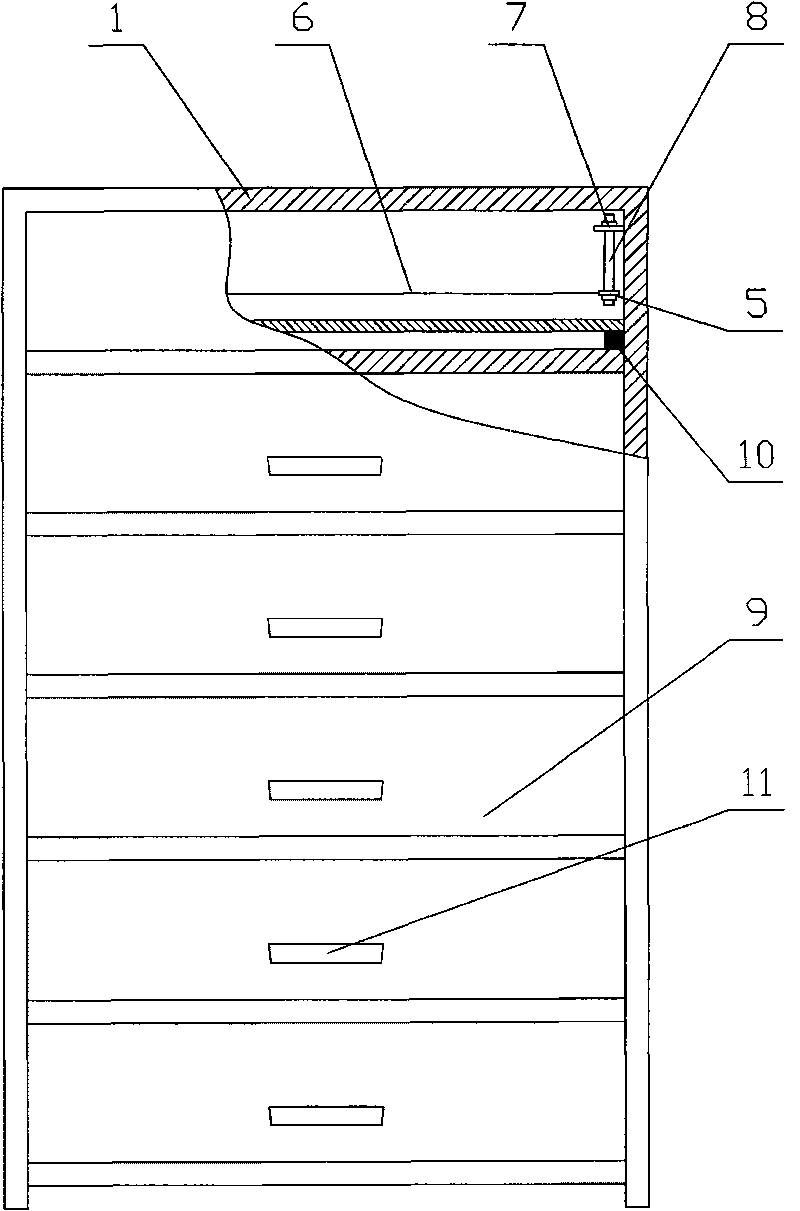

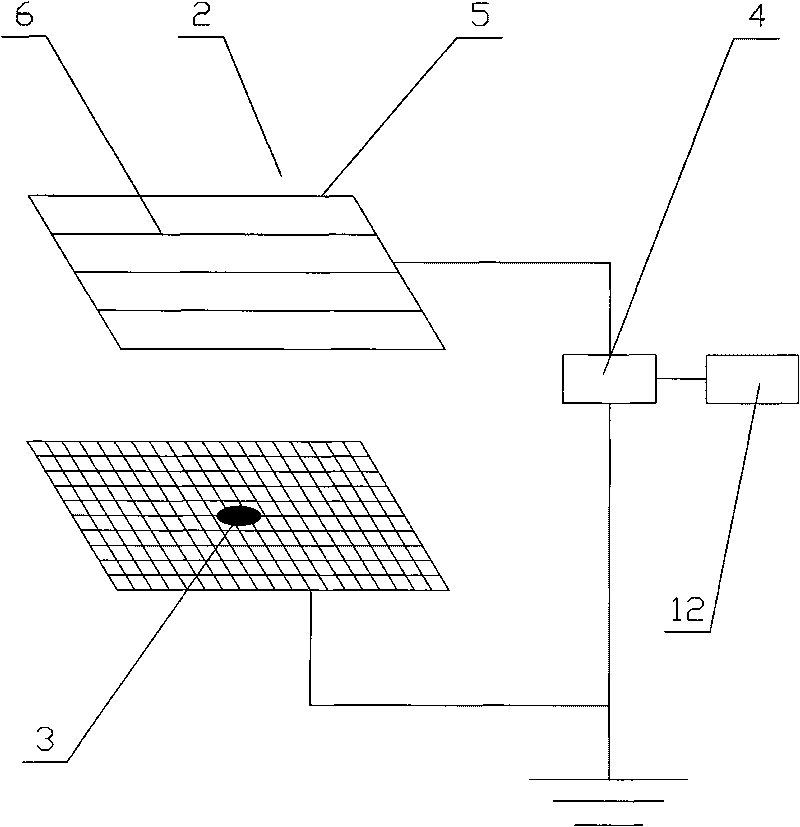

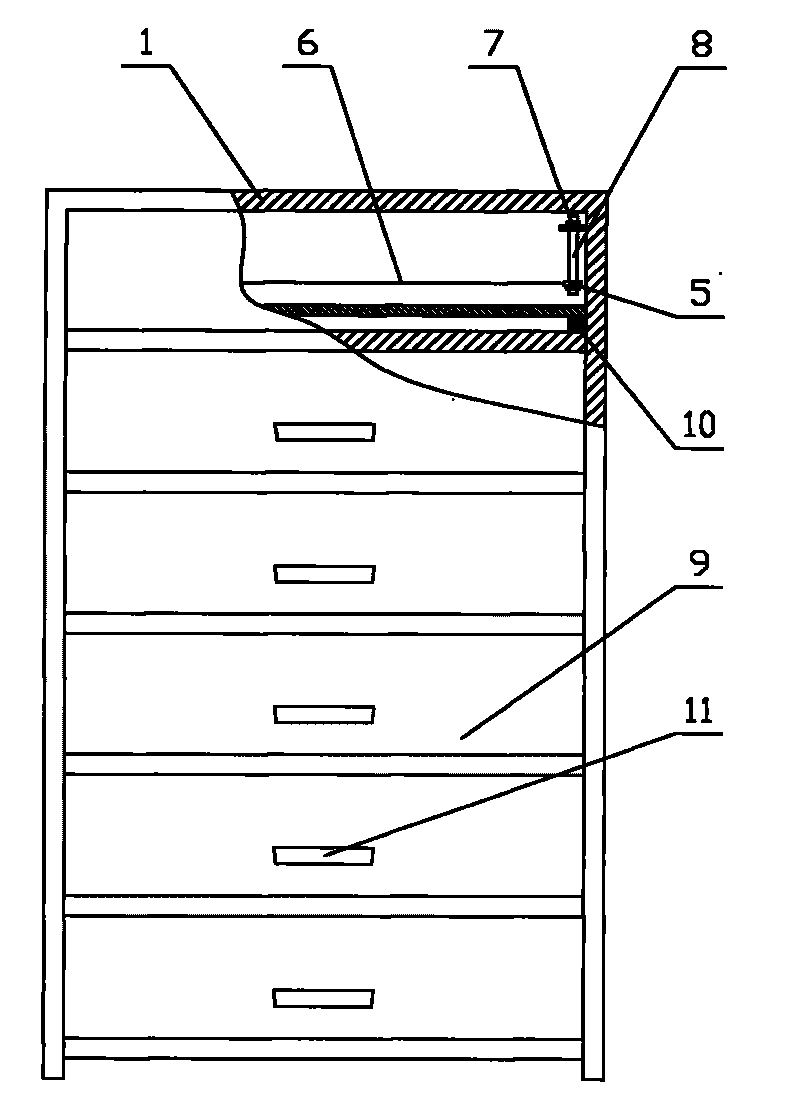

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 As shown, there is a box body 1 as in the prior art. In the box body 1, there are high-voltage electrode plates 2 and flat bottom electrodes 3 parallel to each other. A voltage regulator 12 is connected to the high voltage generator 4 . Different from the prior art, the high-voltage electrode plate 2 is composed of a metal frame 5 parallel to the plate lower electrode 3 and a plurality of mutually parallel metal wires 6 connected to the metal frame 5 at both ends, that is, the metal frame 5 and the metal frame 5 are connected to each other. The high-voltage electrode plate 2 formed by the line 6 is parallel to the lower electrode 3 of the plate, and the output of the high-voltage generator 4 is connected to the metal frame 5 . The diameter of the metal wires 6 is 0.02-0.1 mm, the distance between each metal wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com