Method for preparing thin hydrophobisation layer

A catalytic layer and thin layer technology, applied in the field of proton exchange membrane fuel cells, can solve the problems of insufficient hydrophobicity, etc., and achieve the effect of improving complete hydrophilic characteristics, improving performance, and good three-phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare a 5wt.% PTFE emulsion and use ultrasonic vibration to uniformly stand by, weigh 20 mg of 50 wt.% Pt / C catalyst with a primary balance, moisten it with distilled water, add 10ml of isopropanol, and disperse the catalyst completely by ultrasonic vibration, then Weigh 29.5mg of 5wt.% PTFE emulsion, and continue to vibrate ultrasonically for 2h. Take an aluminum foil with a smooth surface and an effective area of 5cm×5cm, and spray the prepared slurry directly on the aluminum foil. Then it was placed in a nitrogen-filled oven and fired at 240°C for 30 minutes, and then baked at 340°C for 30 minutes. Weigh 160mg of 5wt.% Nafion solution, dilute it with isopropanol, and spray it directly on the catalytic layer. Then the three-dimensional catalytic layer was kept at 150° C. for 2 minutes under 15 Kg·N, and then pressed onto the N212 membrane to form a CCM.

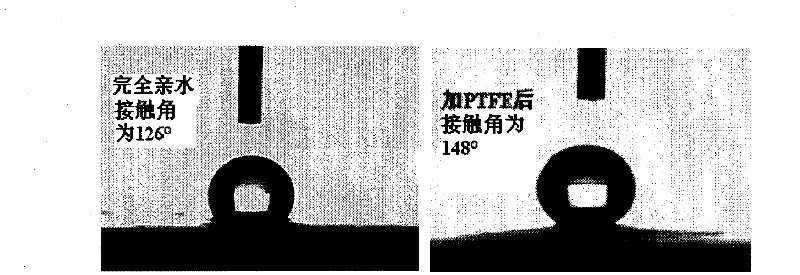

[0025] Test the contact angle of CCM obtained by this method, and compare it with the contact angle of compl...

Embodiment 2

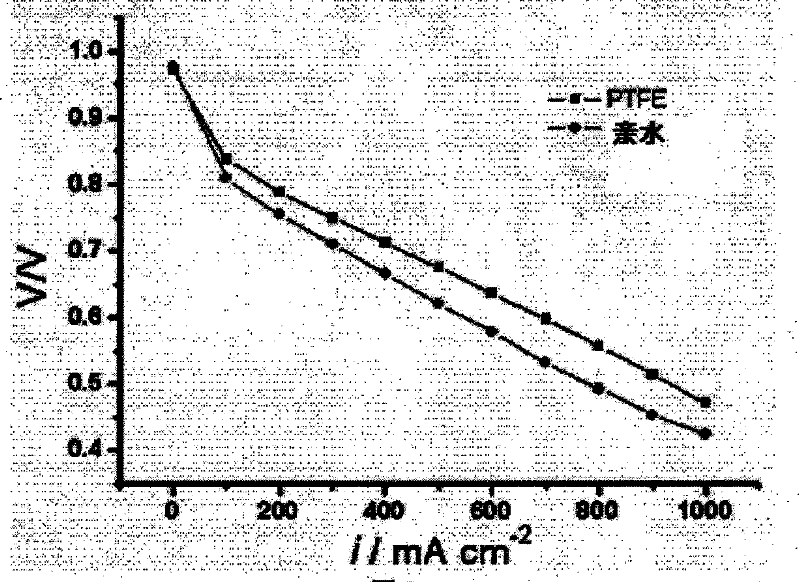

[0027] The difference from Example 1 is that: 25mg of 40wt.% catalyst and 23mg of 5wt.% PTFE emulsion are selected to prepare catalyst slurry, and the Nafion solution sprayed subsequently is 240mg. The prepared CCM is assembled into a battery, and its performance is compared with that of a conventional hydrophilic CCM such as figure 2 shown. from figure 2 It can be seen that the performance of the CCM after adding PTFE has been significantly improved compared with that of the completely hydrophilic CCM, indicating that the CCM prepared by the invention improves the battery performance and avoids the water flooding of the catalytic layer.

Embodiment 3

[0029] The difference from Example 1 is that the temperature of the pressure turning process is 150° C., the pressure is increased to 20 Kg·N, and the holding time is 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com