Method for preparing positive pole of composite metal-ceramic nanofiber SOFC (Solid Oxide Fuel Cell) by electrospinning method

A composite metal and nanofiber technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor thermal stability, achieve low manufacturing costs, high specific surface area and porosity, and fast and convenient methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

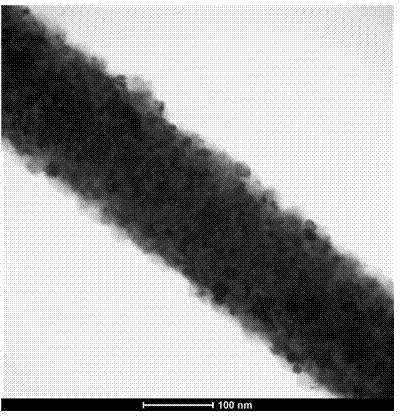

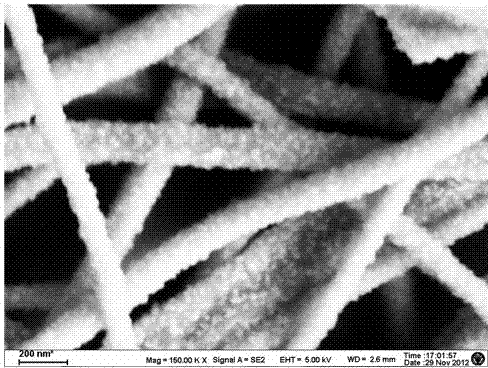

[0023] Ni-SDC composite nanofibers were prepared by electrospinning, Ni and SDC(Ce 0.8 SM 0.2 o 1.9 ) with a mass ratio of 30:70 and a sintering temperature of 700°C for 4 hours:

[0024] a) Weigh 0.35g nickel acetate, 0.39g cerium nitrate and 0.1g samarium nitrate, dissolve them in 2.5ml dimethylformamide (DMF), then add 0.25g polyvinylpyrrolidone (PVP) and stir well.

[0025] b) Composite nanofibers containing PVP and Ni-SDC precursors prepared by electrospinning. The electrospinning electrostatic voltage is 18KV, the flow rate is 0.3mL / h, the receiving distance is 10cm, the temperature is 30°C, and the humidity is 50%.

[0026] c) The obtained composite fibers were sintered at 700 °C in air for 4 h to obtain NiO-SDC composite nanofibers.

[0027] d) NiO-SDC composite nanofibers in H 2 Reduction at 750°C for 2 hours to obtain Ni-SDC anode material.

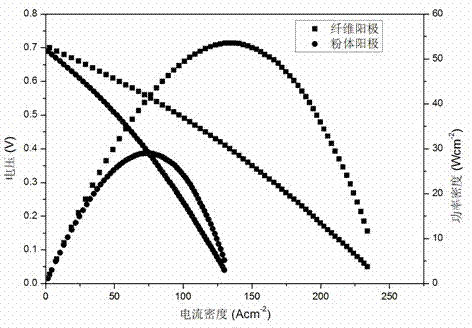

[0028] e) The Ni-SDC anode material was loaded on the half-cell supported by the SDC electrolyte and the LSM-SDC powder ...

Embodiment 2

[0031] Ni-SDC composite nanofibers were prepared by electrospinning, Ni and SDC(Ce 0.8 SM 0.2 o 1.9 ) with a mass ratio of 30:70 and a sintering temperature of 750°C for 3 hours:

[0032] a) Weigh 0.35g nickel acetate, 0.39g cerium nitrate and 0.1g samarium nitrate, dissolve them in a mixed solution consisting of 2.5ml DMF, 1.5ml acetone and 0.5ml glacial acetic acid, then add 0.12g PVP and stir well.

[0033] b) Composite nanofibers containing PVP and Ni-SDC precursors prepared by electrospinning. The electrospinning electrostatic voltage is 30KV, the flow rate is 0.1mL / h, the receiving distance is 8cm, the temperature is 10°C, and the humidity is 10%.

[0034] c) The obtained composite fibers were sintered at 750 °C in air for 3 h to obtain NiO-SDC composite nanofibers.

[0035] d) NiO-SDC composite nanofibers in H 2 Reduction at 800°C for 1 h to obtain Ni-SDC anode material.

[0036] e) The Ni-SDC anode material was loaded on the half-cell supported by the SDC electro...

Embodiment 3

[0039] Ni-SDC composite nanofibers were prepared by electrospinning, Ni and SDC(Ce 0.8 SM 0.2 o 1.9 ) with a mass ratio of 60:40 and a sintering temperature of 700°C for 4 hours:

[0040] a) Preparation of Ni-SDC composite nanofiber spinning solution. Weigh 1.2g of nickel acetate, 0.39g of cerium nitrate and 0.1g of samarium nitrate, respectively dissolve them in a mixed solution consisting of 2ml of deionized water, 2ml of absolute ethanol and 1ml of acetone, then add 1.31g of PVP and stir thoroughly.

[0041]b) Composite nanofibers containing PVP and Ni-SDC precursors prepared by electrospinning. The electrospinning electrostatic voltage is 25KV, the flow rate is 0.5mL / h, the receiving distance is 12cm, the temperature is 25°C, and the humidity is 45%.

[0042] c) The obtained composite fibers were sintered at 700 °C in air for 4 h to obtain NiO-SDC composite nanofibers.

[0043] d) NiO-SDC composite nanofibers in H 2 Reduction at 750°C for 2 hours to obtain Ni-SDC ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com