Central air-conditioning condenser online cleaning system

A technology for central air conditioning and cleaning systems, applied in the field of cleaning systems, can solve problems such as rubber balls being easily blocked at the outlet of the return ball, affecting the working stability of the system, and rising water pressure in the system, achieving good cleaning effects, avoiding pressure rises, The effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

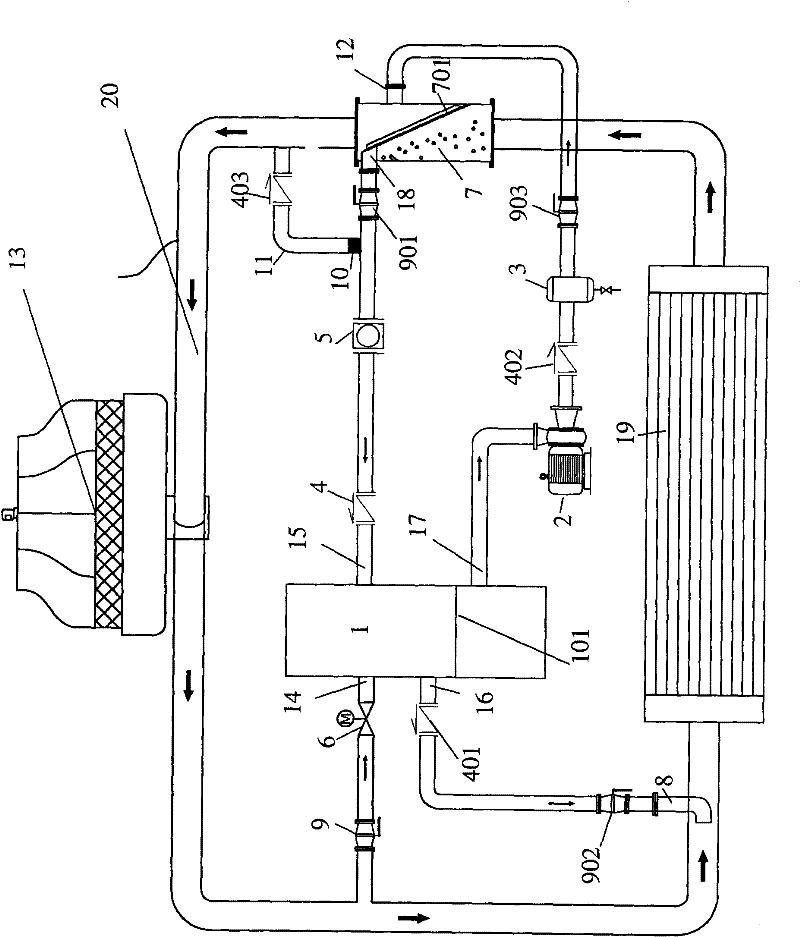

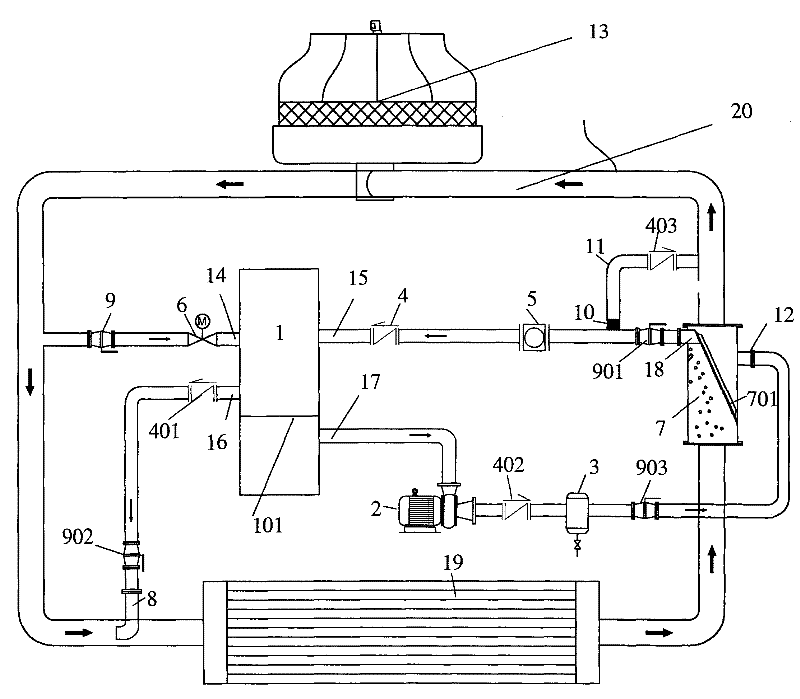

[0028] A central air-conditioning condenser online cleaning system, such as figure 1 As shown, it includes: a ball loading device 1, a condenser 19, a ball collecting device 7, and the two ends of the condenser 19 are connected to a cooling pipe 20. The described ball loading device 1 is divided into upper and lower containers by a grid 101. Glue balls are set in the upper container of the ball loading device 1, and a water inlet 14, a ball return port 15, and a ball outlet 16 are set; the pipeline that the water inlet 14 communicates with the cooling water pipeline 20 is a water inlet pipeline; The pipeline that communicates with the ball sprayer 8 is a ball delivery pipeline, and the spout of the ball sprayer 8 is inserted into the cooling water pipeline 20 at the condenser inlet; A branch 11 is arranged on the cooling water return pipe, a check valve 403 is arranged in the branch 11, and a screen 10 is arranged between the branch and the return pipe. The system water can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com