Method for treating discharged waste gas of acid water tank area

A technology for acid water and waste gas treatment, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems of no treatment method, large adsorption reaction heat release, and decreased desulfurization effect, so as to achieve no secondary pollution. Secondary pollution, low exhaust emissions, and small equipment scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

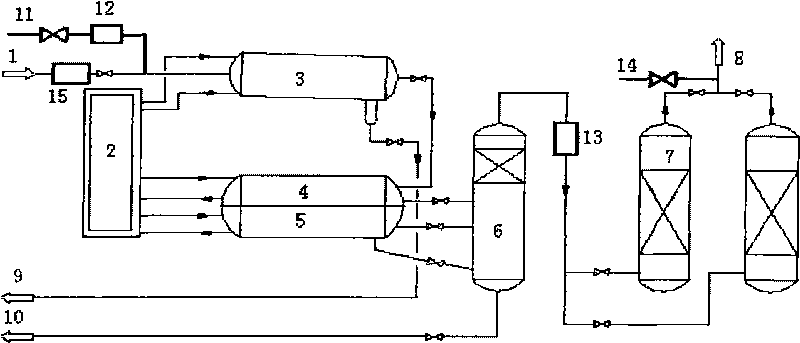

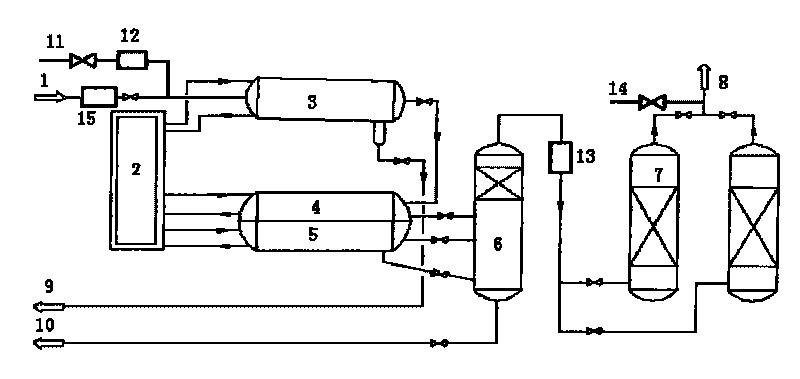

[0024] The method of the present invention will be further explained below in conjunction with the drawings.

[0025] Such as figure 1 As shown, during the exhaust period of the storage tank area, the exhaust gas 1 discharged from the storage tank area first passes through the elastic breathing air chamber 15 (one or several emission reduction measures can be adopted, figure 1 In this case, an elastic breathing chamber is used. After the elastic breathing chamber 15 is full, exhaust gas is discharged to the exhaust gas treatment system. The exhaust gas passes through the first-stage condensation zone 3, the second-stage condensation zone 4 and the third-stage condensation zone 5 in sequence, and all the condensation zones are connected to the refrigeration unit 2. In the primary condensation zone, the condensate 9 is mainly water, which can be further processed. In the secondary and tertiary condensing zones, the condensate 10 is mainly organic volatiles, which are separated an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com