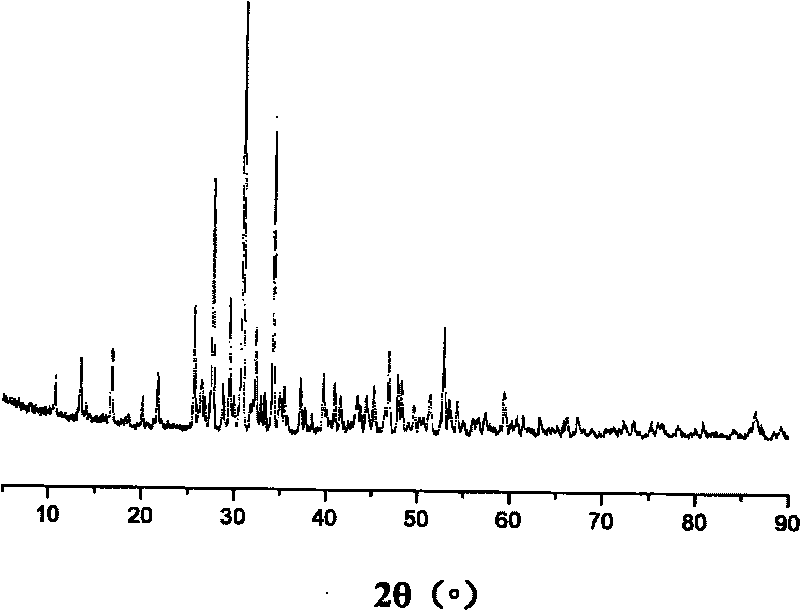

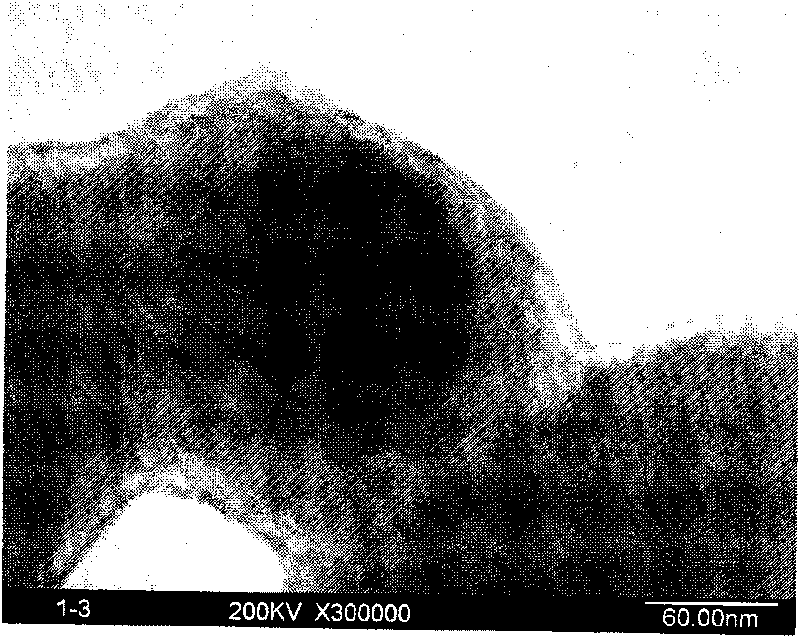

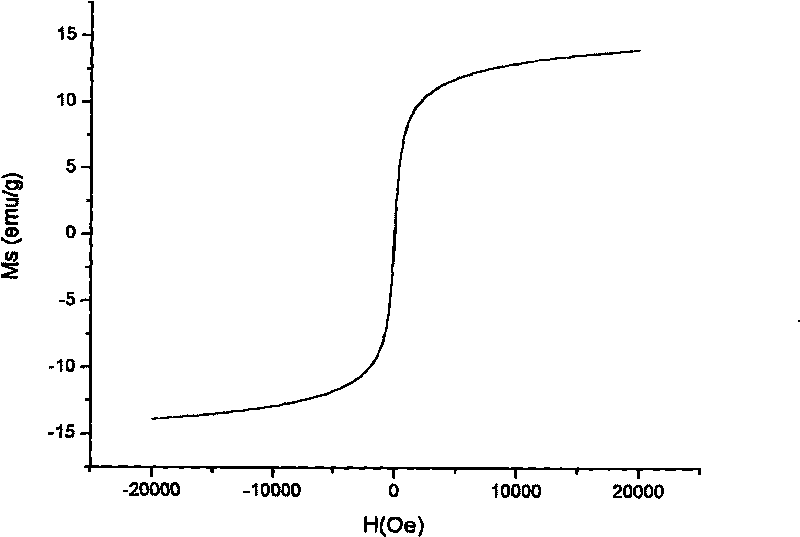

Ferroferric oxide/calcium phosphate nuclear shell structure nano particle and preparation method thereof

A technology of ferroferric oxide and nanoparticles, applied in medical science, prosthesis, etc., can solve the problems that have not been reported, and achieve the effect of accelerating the biomineralization process, promoting repair and regeneration, and simple preparation and processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Mix 9.197g ferric chloride hexahydrate with 4.335g ferrous chloride tetrahydrate (molar ratio 2:1) and 80ml deionized water, stir mechanically in a water bath at 40°C, and add 80ml 3mol / L of Sodium hydroxide solution, after the completion of the reaction, use the magnetite to collect the ferric oxide, rinse with deionized water and ethanol for 3 times each. Dry at 60° C. for 12 hours to obtain ferric oxide nanoparticles. Mix 0.2g iron ferric oxide nanoparticles, 1g sodium citrate and 20ml deionized water, mechanically stir in a water bath at 40°C for 12 hours, centrifuge at 10000r / min to remove the supernatant, add deionized water to separate and remove the supernatant again , poured into 30ml of deionized water and centrifuged to obtain the supernatant, which was stable ferroferrogen tetroxide magnetic fluid with a mass concentration of 1.05%.

[0026] (2) Mix 3.643g triethyl phosphate, 2.76g ethanol and 1.08g deionized water to form a solution, and add nitric aci...

Embodiment 2

[0031](1) Mix 9.197g of ferric chloride hexahydrate with 4.621g of ferrous chloride tetrahydrate and 80ml of deionized water, mechanically stir in a water bath at 40°C, add 70ml of 3mol / L sodium hydroxide solution dropwise, and react After completion, collect the prepared ferric oxide with a magnet, rinse with deionized water and ethanol three times each. Dry at 60° C. for 12 hours to obtain ferric oxide nanoparticles. Mix 0.8g of ferric oxide, 1g of sodium citrate and 20ml of deionized water, mechanically stir in a water bath at 40°C for 12 hours, centrifuge at a speed of 10,000r / min to remove the supernatant, add deionized water to separate and remove the supernatant again, pour Add 30 ml of deionized water and centrifuge to obtain the supernatant, which is a stable ferroferrogen tetroxide magnetic fluid with a mass concentration of 1.05%.

[0032] (2) Mix 3.643g of triethylphosphoric acid, 2.76g of ethanol and 1.08g of deionized water to form a solution, and dropwise add n...

Embodiment 3

[0036] (1) Mix 9.197g of ferric chloride hexahydrate with 5.124g of ferrous chloride tetrahydrate and 80ml of deionized water, mechanically stir in a water bath at 40°C, add 60ml of 3mol / L sodium hydroxide solution dropwise, and react After completion, collect the prepared ferric oxide with a magnet, rinse with deionized water and ethanol three times each. Dry at 60° C. for 12 hours to obtain ferric oxide nanoparticles. Mix 1.0g of ferric oxide, 1g of sodium citrate and 20ml of deionized water, mechanically stir in a water bath at 40°C for 12 hours, centrifuge at a speed of 10,000r / min to remove the supernatant, add deionized water to separate and remove the supernatant again, pour Add 30 ml of deionized water and centrifuge to obtain the supernatant, which is a stable ferroferrogen tetroxide magnetic fluid with a mass concentration of 1.05%.

[0037] (2) Mix 3.643g tributylphosphoric acid, 2.76g ethanol and 1.08g deionized water to make a solution, and add nitric acid dropwi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com