Stabilizer composition, application thereof and milk beverage containing same

A composition and milk beverage technology, applied in the application, dairy products, food science and other directions, can solve the problems that the product stability cannot meet the long shelf life of consumers, the precipitation of insoluble substances, and the short development history, and achieve outstanding stability. The effect of less sedimentation and uniform particle suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

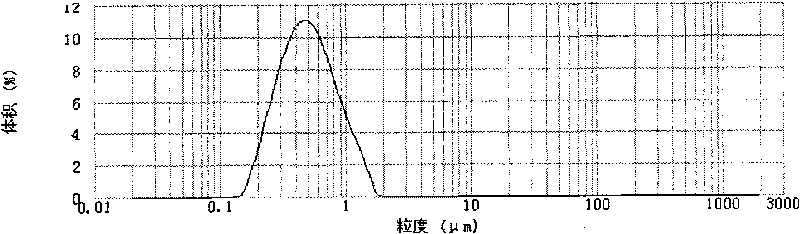

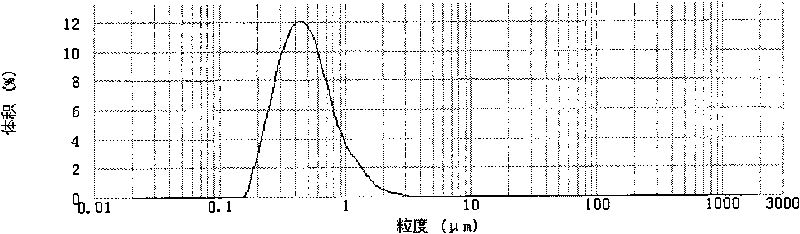

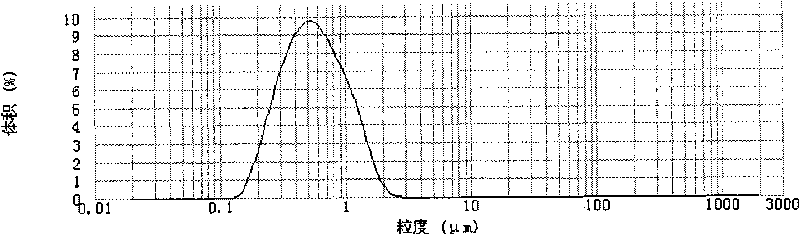

Image

Examples

Embodiment 1

[0031] Embodiment 1, sweet neutral milk drink

[0032] The formula of the milk drink of the present embodiment is (in terms of one ton of product):

[0033] Milk 700kg

[0034] White sugar 50kg

[0035] Stabilizer 1.833 kg

[0036] Food flavor 1.1 kg

[0037] water balance.

[0038] Wherein, the stabilizer used is composed of kappa carrageenan, guar gum, sodium alginate, sodium carboxymethyl cellulose, monoglyceride, sodium stearoyl lactylate according to the weight ratio of 0.04:0.3:0.15:0.013:1.2:0.13 composition. The performance indicators of the raw materials used meet the requirements of relevant quality standards.

[0039] The production process used in this example is a conventional dairy production process. For example, the process flow can be as follows: raw milk inspection→milk collection (1°C-8°C)→storage→clean milk (removing mechanical impurities in raw milk)→pasteurization Sterilization (85°C±5°C / 15s, cooling to 1°C-8°C after sterilization)→Batching (heat t...

Embodiment 2

[0042] Embodiment 2, matcha flavor neutral milk drink

[0043] The formula of the milk drink of the present embodiment is (in terms of one ton of product):

[0044] Milk 600kg

[0045] White sugar 50kg

[0046] Stabilizer 2.66 kg

[0047] Matcha Flavor Food Flavor 1.1kg

[0048] water balance.

[0049] Wherein, the stabilizer used is composed of κ-type carrageenan, guar gum, sodium alginate, sodium carboxymethyl cellulose, monoglyceride, sodium stearoyl lactylate according to the weight ratio of 0.08:0.3:0.6:0.1:1.5:0.08 composition. The performance indicators of the raw materials used meet the requirements of relevant quality standards. The production process used is a conventional dairy product production process.

[0050] The characteristics of the matcha-flavored neutral milk beverage product of this embodiment are: the fat content is about 1.9%, the protein content is about 1.7%, and the product viscosity is about 3.68~4.31 centipoise (No. 0 rotor of Brookfield LVD...

Embodiment 3

[0051] Embodiment 3, strawberry flavor neutral milk drink

[0052] The formula of the milk drink of the present embodiment is (in terms of one ton of product):

[0053] Milk 450kg

[0054] 45kg white sugar

[0055] Stabilizer 1.78 kg

[0056] Strawberry Flavor Food Flavor 1.0kg

[0057] water balance.

[0058] Wherein, the stabilizer used is composed of κ-type carrageenan, guar gum, sodium alginate, sodium carboxymethylcellulose, monoglyceride, sucrose fatty acid ester according to the weight ratio of 0.06:0.5:0.4:0.02:0.3:0.5 composition. The performance indicators of the raw materials used meet the requirements of relevant quality standards. The production process used is a conventional dairy product production process.

[0059] The characteristics of the strawberry flavor neutral milk beverage product of the present embodiment are: fat content is about 1.4%, protein content is about 1.3%, product viscosity is about 2.81~3.14 centipoise (No. 0 rotor of Brookfield LVDV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com