PIV trace particles for wind tunnels and preparation method thereof

A technology for tracking particles and wind tunnels, which is used in measurement devices, instruments, aerodynamic tests, etc., can solve the problems of increasing wind tunnel experiment costs, high polymer particle preparation costs, and wind tunnel pollution, etc., and achieves a good flow field. The effect of followability, low experimental test cost, and good flow field followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

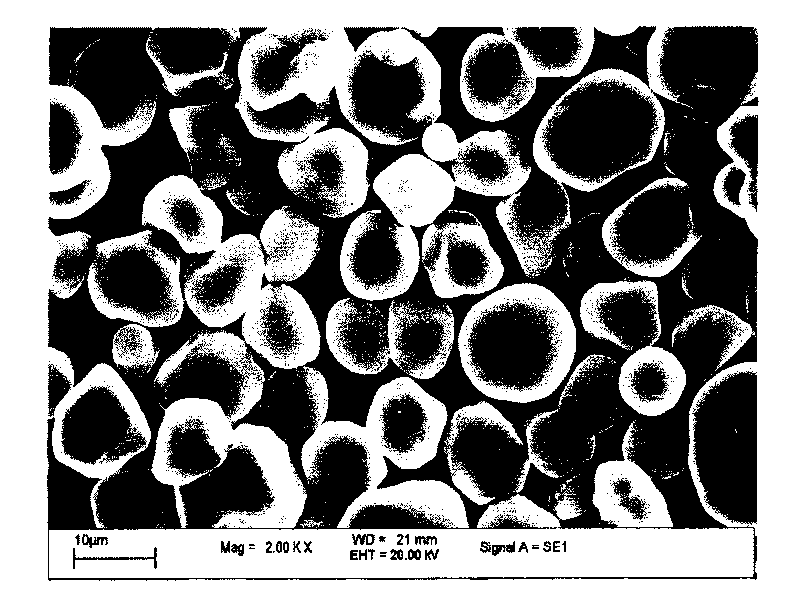

[0032] Example 1: Preparation of PIV tracer particles with an average particle size of 13.4 μm

[0033] Core core: choose corn starch granule material;

[0034] Modifier: select the coupling agent compounded by titanate coupling agent NDZ-401 and silane coupling agent A-151, wherein the compounding ratio is NDZ-401:A-151=2:1.

[0035] making process:

[0036] The first step: through the method of jet milling, under the conditions of the crushing airflow pressure of 0.6MPa and the speed of the classification wheel of 2000r / min, the corn starch granules are ultrafinely pulverized, and the average particle size of the pulverized starch granules is 13.4 μm;

[0037] The second step: drying the cornstarch with an average particle size of 13.4 μm prepared in the first step for 3 hours at 110° C. to obtain dry core particles;

[0038] The third step: the dried core particles and modifier obtained in the second step are placed in a high-speed mixer (select SHR-5A high-speed mixer,...

Embodiment 2

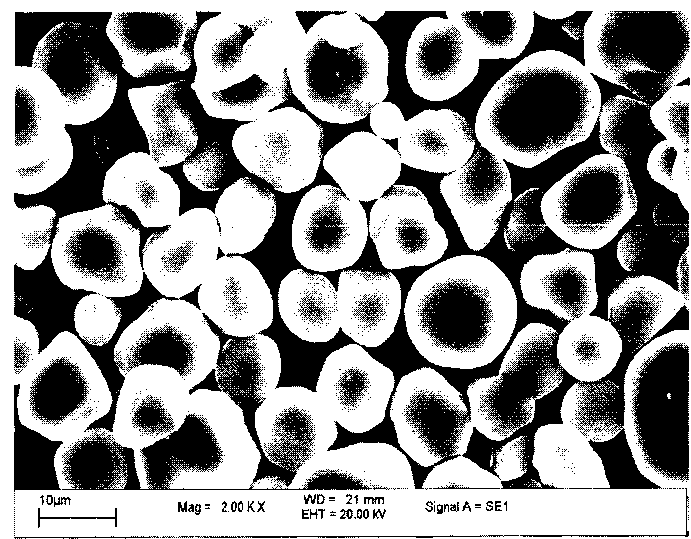

[0042] Example 2: Preparation of PIV tracer particles with an average particle size of 7.6 μm

[0043] Core core: choose rapeseed pollen granular material;

[0044] Modifier: choose aluminate coupling agent DL-2411-A.

[0045] making process:

[0046] The first step: through the method of vibrating mill crushing, after crushing for 3 hours, rapeseed pollen fine particle materials with an average particle size of 7.6 μm are obtained;

[0047] The crushing conditions of the vibration mill are: the vibration frequency is 55 Hz, the amplitude is 5 mm, the grinding medium is zirconia balls of three diameters, and the amount of different grinding media is 8 mm zirconia balls: 5 mm zirconia balls: 2 mm zirconia balls = 5:3 : 2, the crushing time is 30min;

[0048] Dosage: The mass ratio of rapeseed pollen granular material to grinding medium is 1:2;

[0049] In this step, the rapeseed pollen granular material and the grinding medium account for 80% of the cavity volume of the vib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com