Solvent thermal induction control synthesis method for nano molybdate with scheelite structure

A synthesis method and molybdate technology, which are applied in the fields of nanostructure manufacturing, molybdenum compounds, nanotechnology, etc., can solve the problems of inconvenient post-processing and reduced product purity, and achieve easy control of size and structure, high product purity, and enhanced fluorescence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) In the container, add oily solvent absolute ethanol and sodium molybdate solution with a concentration of 0.2mol / L in sequence according to the volume ratio of 0-3:1, and perform ultrasonic treatment. Add lead chloride solution, wherein the molar amount of lead is equal to the molar amount of molybdenum in sodium molybdate, after ultrasonication for 30 minutes, transfer it to a stainless steel autoclave, and ensure that the volume of the reaction solution is two-thirds of the volume of the autoclave , after the autoclave is sealed, put it into an electric heating constant temperature oven at 160°C, heat it for 4 hours, close the oven, and take it out after it cools to room temperature;

[0026] (2) The supernatant in the autoclave is sucked out, and the lower white precipitate collected is washed three times with acetone, distilled water and absolute ethanol successively to obtain the product of the present invention.

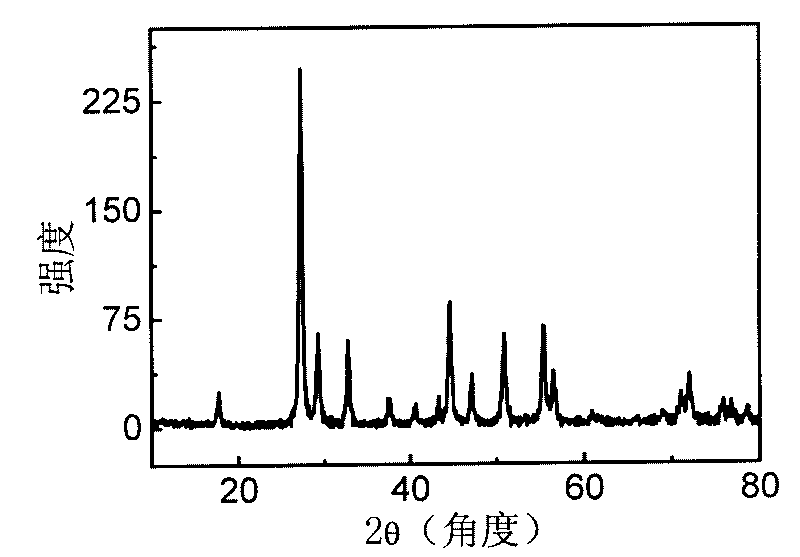

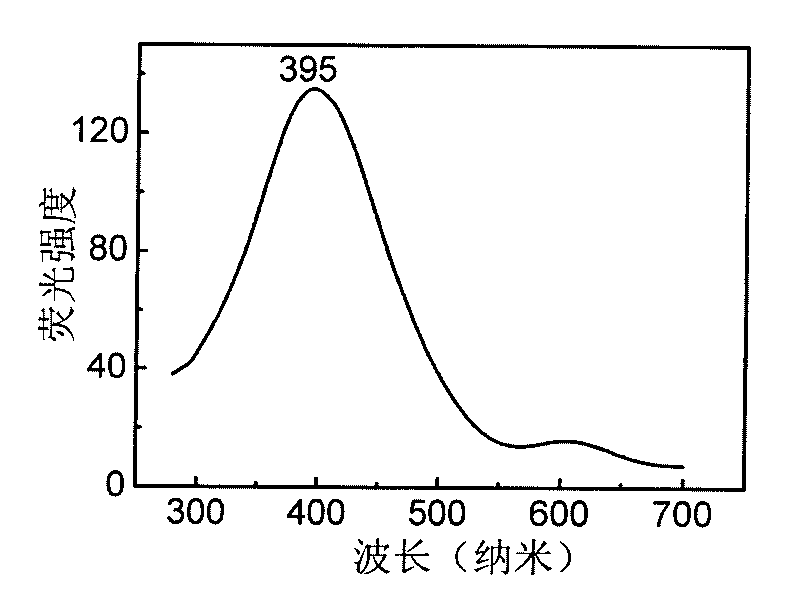

[0027] The morphology and structure of the pro...

Embodiment 2

[0032] Choose the oil-water ratio of 0: 1, change the sodium molybdate that concentration is 0.2mol / L into the potassium molybdate that concentration is 0.4mol / L, other conditions and steps are identical with embodiment 1, the product that obtains is by long 3 μ m , a nano-slab with a width of 220nm and a thickness of 110nm. The crystal system of the product is the same as in Example 1. The product has high purity, good crystallinity and optical properties.

Embodiment 3

[0034] Select the oil-water ratio of 3:1, change dehydrated alcohol into oleic acid, other conditions and steps are exactly the same as in Example 1, the product obtained is a flower cluster structure formed by 80nm nanoplates, the crystal system of the product and the implementation Example 1 is the same, and has good luminous properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com