Method for preparing polymeric micro-fluidic chip based on hydrogel male mold

A technology of microfluidic chips and hydrogels, which is applied to the photolithographic process of patterned surfaces, welding equipment, manufacturing tools, etc., can solve problems such as polymer microfluidic chips that have not yet been seen, and achieve good application prospects, Ease of demolding and reduction of chip manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1. Application of gelatin hydrogel positive mold in the preparation of polymethyl methacrylate microfluidic chip

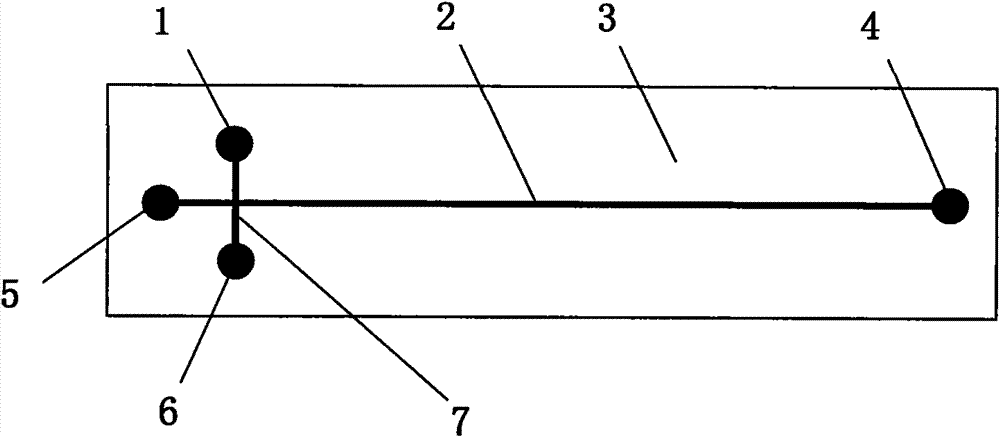

[0037] (1) Design of microfluidic chip

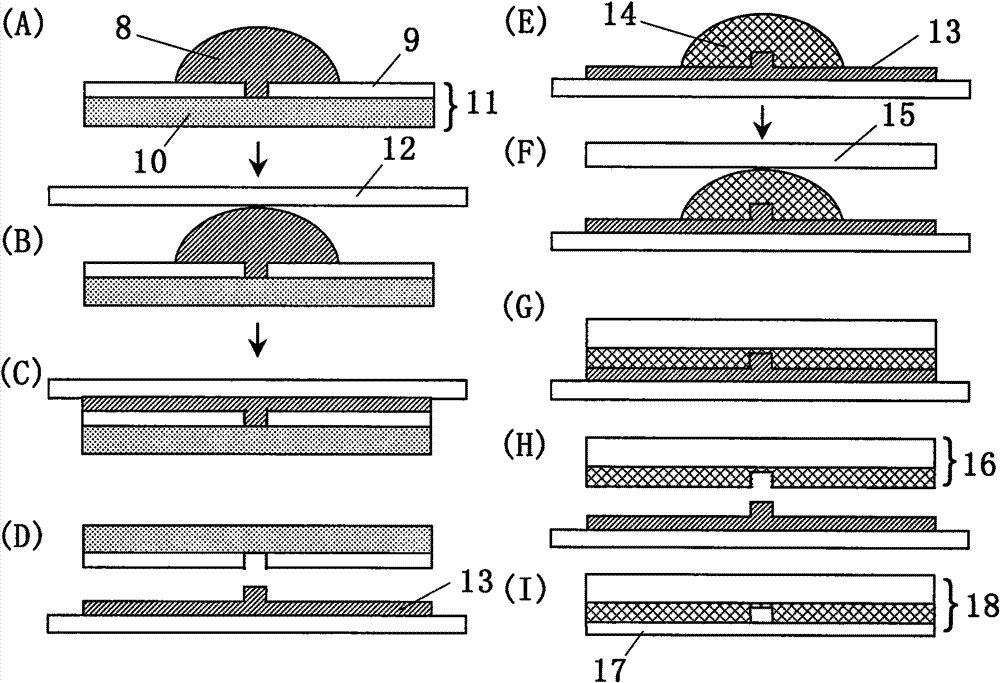

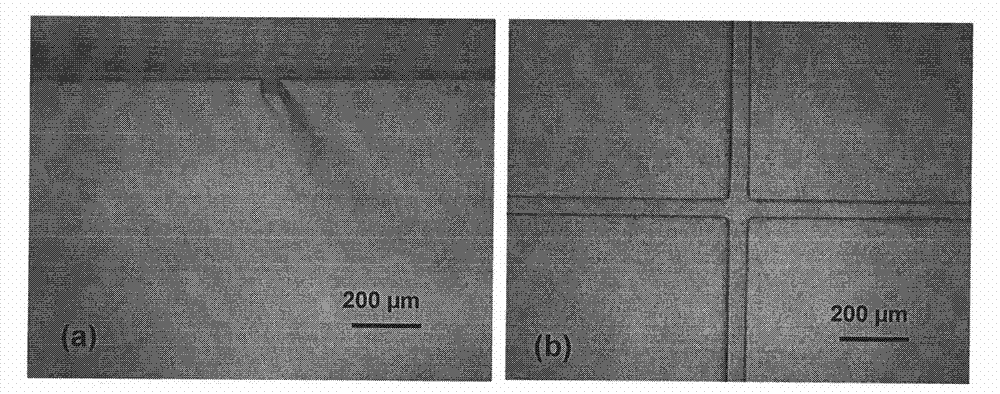

[0038] Adobe Illustrator CS3 software was used to design the microfluidic channel and solution connection hole of the chip, and a high-resolution (3600dpi) laser phototypesetting system was used to print a positive mask on a polyester transparent film. The width of the microfluidic channel on the mask was 50 μm, and the solution The connection hole is a round hole with a diameter of 2mm, in which the microfluidic channel (separation channel 2 and sampling channel 7) and solution holes 1, 4, 5 and 6 (attached figure 1 ) is black and the rest is transparent. The typical design of the microfluidic chip is shown in the appendix figure 1 . The separation microfluidic channel 2 is 65 mm long, and the sampling microfluidic channel 5 is 10 mm long, and the distance from the intersection of microfluidic channels 4 ...

Embodiment 2

[0049] Example 2, the application of agar hydrogel positive mold in the preparation of polydimethylsiloxane and epoxy resin microfluidic chip

[0050] (1) Fabrication of agar hydrogel male mold

[0051] The design of the microfluidic chip and the fabrication of the SU-8 photoresist negative mold 11 are the same as in Example 1.

[0052] After mixing 81.5 grams of water and 5 grams of glycerin (plasticizer) evenly, add 0.5 grams of borax and stir to dissolve it, then disperse 13 agar in the solution, heat to boiling and keep stirring until completely dissolved, and cool to room temperature Elastic gelatin hydrogel impression material.

[0053] Before preparing the agar hydrogel positive mold, the agar hydrogel impression material is placed in a water bath at a temperature of 70° C. to melt. Get 1.5 milliliters of molten hydrogel 8 and cast it on the midline of the long side of the photoresist negative mold 11, and then cover the frosted surface of a preheated frosted glass sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com