A kind of preparation method of lithium ion battery inorganic solid electrolyte thin film

A technology for lithium-ion batteries and electrolyte films, which is applied in the field of preparation of inorganic solid electrolyte films for lithium-ion batteries, can solve problems such as high energy consumption, high production costs, and the need for subsequent heat treatment of films, and achieve excellent electrical performance, less waste, and microscopic The effect of adjustable shape parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

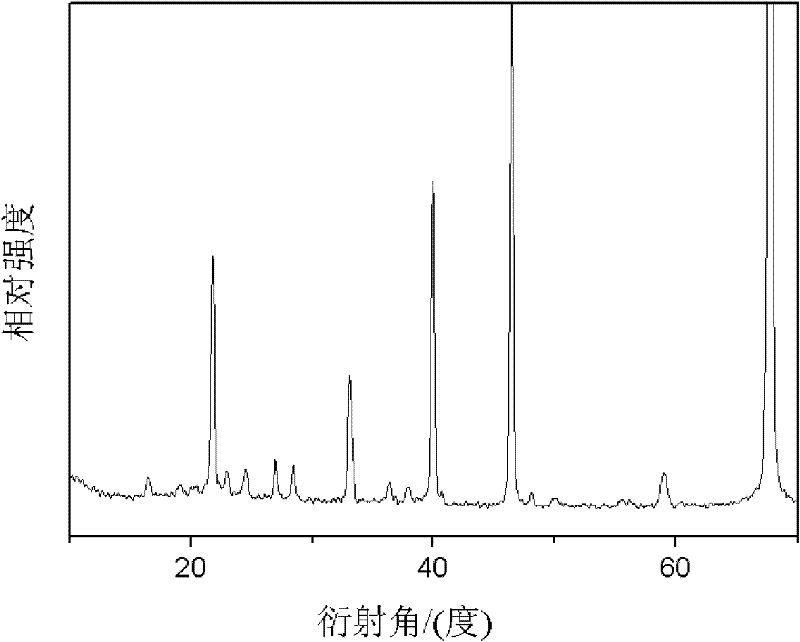

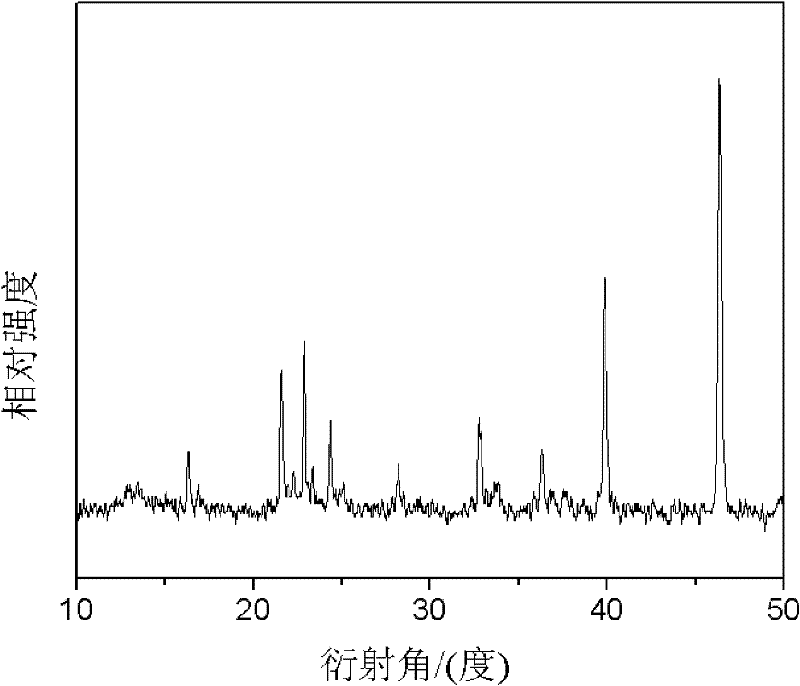

Image

Examples

Embodiment 1

[0032] (1) Polish the Pt sheet, after ultrasonic cleaning in acetone, treat with chromic acid for 16h, then ultrasonically clean and dry with twice distilled water;

[0033] (2) Mix 0.1 to 10 parts of LiOH, 0.1 to 2 parts of SiO under stirring conditions 2 , V 2 o 5 Add 100 parts of methanol organic solvent to form a turbid solution;

[0034] (3) Put the turbid liquid into a reaction kettle with a polytetrafluoroethylene liner;

[0035] (4) The reaction system in the reactor is connected to the external electric field through three electrodes;

[0036] (5) The three electrodes are respectively the Pt sheet as the working electrode, the Pt sheet as the counter electrode, and the Ag / AgCl electrode as the reference electrode;

[0037] (6) Control the temperature of the reaction system between 180°C and the current density at 0.0001~5mA / cm 2 , the reaction time is 10 to 24 hours;

[0038] (7) The working electrode after the reaction is washed with ethanol and deionized water...

Embodiment 2

[0041] (1) Polish the Pt sheet, after ultrasonic cleaning in acetone, treat with chromic acid for 16h, then ultrasonically clean and dry with twice distilled water;

[0042] (2) Mix 0.1 to 10 parts of LiOH, 0.1 to 2 parts of NH under stirring conditions 4 h 2 PO 4 , V 2 o 5 Add 100 parts of ethanol organic solvent to form a turbid solution;

[0043] (3) Put the turbid liquid into a reaction kettle with a polytetrafluoroethylene liner;

[0044] (4) The reaction system in the reactor is connected to the external electric field through three electrodes;

[0045] (5) The three electrodes are respectively the Pt sheet as the working electrode, the Pt sheet as the counter electrode, and the Ag / AgCl electrode as the reference electrode;

[0046] (6) Control the temperature of the reaction system between 150°C and the current density at 0.0001~5mA / cm 2 , the reaction time is 10-20 hours;

[0047] (7) The working electrode after the reaction is washed with ethanol and deionized w...

Embodiment 3

[0050] (1) Polish the negative electrode of lithium ion battery C, after ultrasonic cleaning in acetone, then ultrasonic cleaning with twice distilled water, blow dry;

[0051] (2) Add 0.1 to 10 parts of LiNO under stirring condition 3 , 0.1 to 2 parts of NH 4 h 2 PO 4 Add 100 parts of methanol organic solvent to form a turbid solution;

[0052] (3) Put the turbid liquid into a reaction kettle with a polytetrafluoroethylene liner;

[0053] (4) The reaction system in the reactor is connected to the external electric field through three electrodes;

[0054] (5) The three electrodes are the negative electrode of lithium ion battery C, the working electrode, the Pt sheet as the counter electrode, and the Ag / AgCl electrode as the reference electrode;

[0055] (6) Control the temperature of the reaction system between 120°C and the current density at 0.0001~5mA / cm 2 , the reaction time is 1 to 20 hours;

[0056] (7) The working electrode after the reaction is washed with etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com