Method and device for purifying trichlorosilane

A technology of trichlorosilane and purification method, which is applied in the direction of halosilane and silicon halide compounds, which can solve the problems of high equipment requirements and inability to meet electronic grade polysilicon, so as to avoid secondary pollution, reduce energy consumption, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

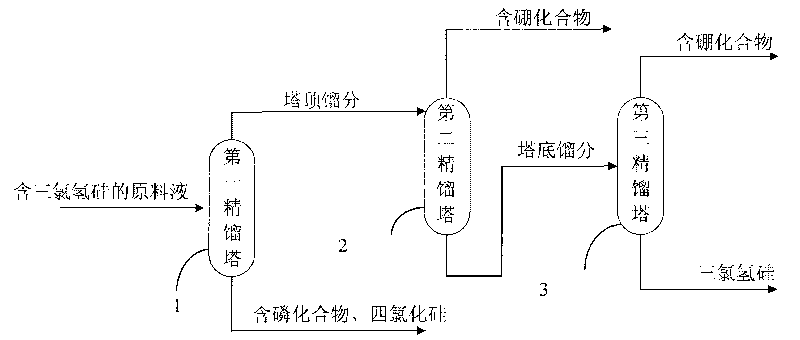

[0065] The raw material is crude chlorosilane, which contains 80ppma of boron trichloride, 50ppma of phosphorus trichloride, 80% of trichlorosilane, and the rest is other impurities.

[0066] The crude chlorosilane is continuously added to tower 1 at a flow rate of 1000kg / h, and the operating conditions of tower 1 are as follows:

[0067] The operating pressure is 0.2MPa, the temperature at the top of the tower is 55°C, the temperature at the bottom of the tower is 88°C, and the reflux ratio is 3.

[0068] Cut off the top fraction of 800kg / h and add it to tower 2, and the bottom fraction of 200kg / h will be collected and processed separately.

[0069] The operating conditions of column 2 are as follows: the operating pressure is 0.2 MPa, the temperature at the top of the column is 51° C., the temperature at the bottom of the column is 60° C., and the reflux ratio is 3100.

[0070] The 798kg / h bottom fraction of interception tower 2 enters tower 3, and the tower top fraction of...

Embodiment 2

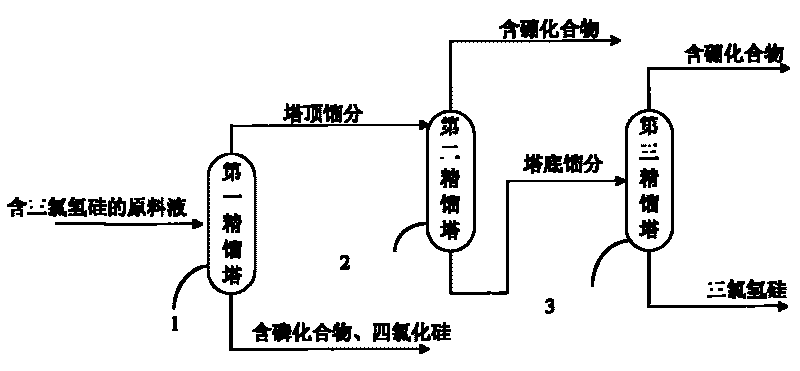

[0076] The raw material is crude chlorosilane, which contains 60ppma of boron trichloride, 30ppma of diborane, 50ppma of phosphorus trichloride, 80% of trichlorosilane, and the rest is other impurities.

[0077] The crude chlorosilane is continuously added to tower 1 at a flow rate of 2000kg / h, and the operating conditions of tower 1 are as follows:

[0078] The operating pressure is 0.10MPa, the temperature at the top of the tower is 32°C, the temperature at the bottom of the tower is 70°C, and the reflux ratio is 9.

[0079] Cut off the top fraction of 1600kg / h and add it to tower 2, and the bottom fraction of 400kg / h will be collected and processed separately.

[0080] The operating conditions of column 2 are as follows: the operating pressure is 0.10 MPa, the temperature at the top of the column is 31° C., the temperature at the bottom of the column is 45° C., and the reflux ratio is 7500.

[0081] The 1596kg / h bottom fraction of interception tower 2 enters tower 3, and t...

Embodiment 3

[0087] The raw material is crude chlorosilane, which contains 80ppma of boron trichloride, 50ppma of phosphorus trichloride, 20ppma of phosphorus pentachloride, contains 80% of trichlorosilane, and the rest is other impurities.

[0088] The crude chlorosilane is continuously added to tower 1 at a flow rate of 1000kg / h, and the operating conditions of tower 1 are as follows:

[0089] The operating pressure is 0.25MPa, the temperature at the top of the tower is 62°C, the temperature at the bottom of the tower is 100°C, and the reflux ratio is 5.

[0090] Cut off the top fraction of 800kg / h and add it to tower 2, and the bottom fraction of 200kg / h will be collected and processed separately.

[0091]The operating conditions of column 2 are as follows: the operating pressure is 0.25MPa, the temperature at the top of the tower is 60°C, the temperature at the bottom of the tower is 66°C, and the reflux ratio is 7000.

[0092] The 798kg / h bottom fraction of interception tower 2 enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com