Production technology for synthesizing high-purity phosphorus pentasulfide by liquid-phase continuous process

A technology of phosphorus pentasulfide and production technology, which is applied in the direction of phosphorus sulfur/selenium/tellurium phosphorus compounds, etc., which can solve the problems of large temperature fluctuations in the reactor, inaccurate raw material ratios, and manufacturers cannot produce at full capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

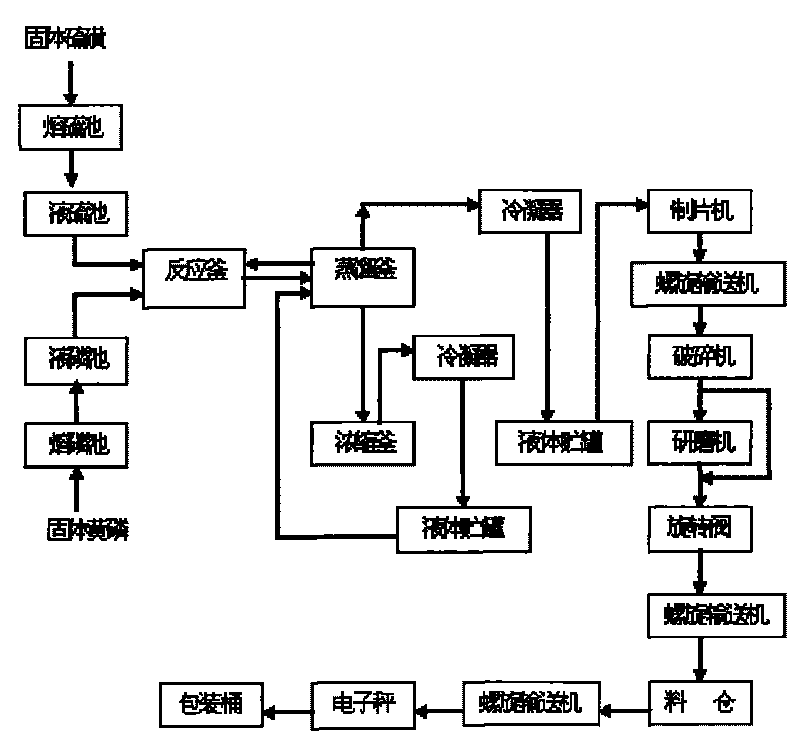

Image

Examples

Embodiment Construction

[0018] After the solid yellow phosphorus and solid sulfur are melted and settled, the liquid yellow phosphorus and liquid sulfur are continuously transported by the pump to the reactor at a ratio of 1:2.6, and the liquid phase reaction is carried out at 400°C, about 0.15Mpa, and with stirring. . The reacted raw materials are continuously pumped into the still, and are distilled under reduced pressure at a temperature of 390°C and an absolute pressure of 8.1Kpa. The phosphorus pentasulfide vapor formed by vacuum distillation is condensed into liquid phosphorus pentasulfide by the condenser, concentrated in the finished product storage tank of phosphorus pentasulfide, and then transported to the tablet machine by the pump, processed into flake products, crushed, ground, and finally packaged into finished products. The product is yellow in appearance, contains 71.7-72.3% sulfur, 27.8-28.2% phosphorus, and has a final melting point ≥ 276°C, meeting the national standard GB13258-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com