Grinding wheel dressing method used for slewing support roller path grinding

A slewing bearing and grinding wheel dressing technology, which is applied in the grinding wheel dressing of slewing bearing raceway grinding, and the processing field of grinding wheel dressing, can solve the problem that affects the machining accuracy and surface quality of the workpiece, and it is difficult to find the crux of the problem, and the processing cannot be carried out normally. and other issues, to achieve the effect of enhancing processing adaptability, enhancing market competitiveness, and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, technical content of the present invention is described:

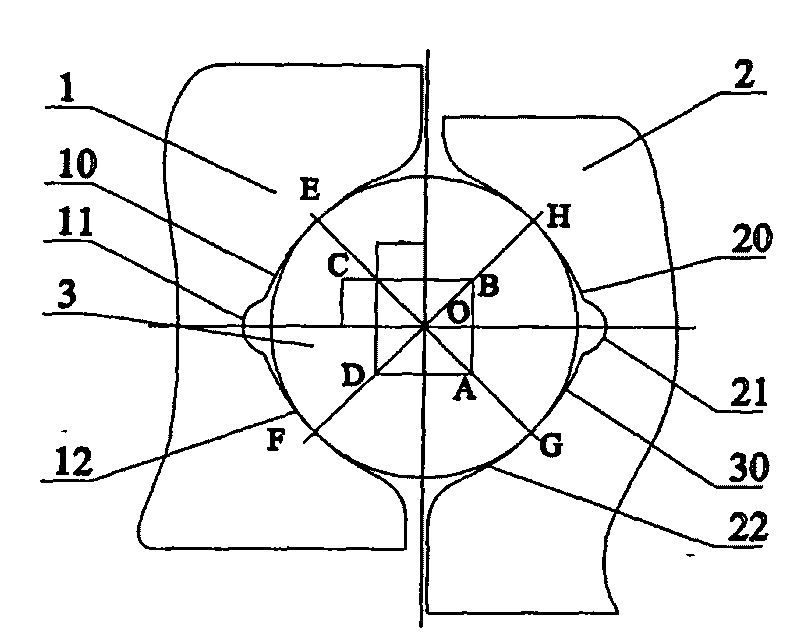

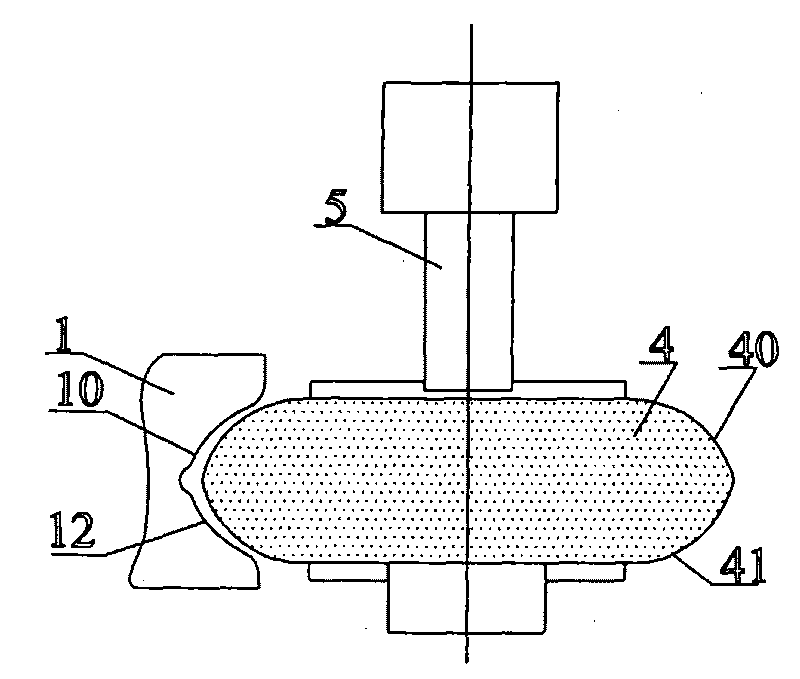

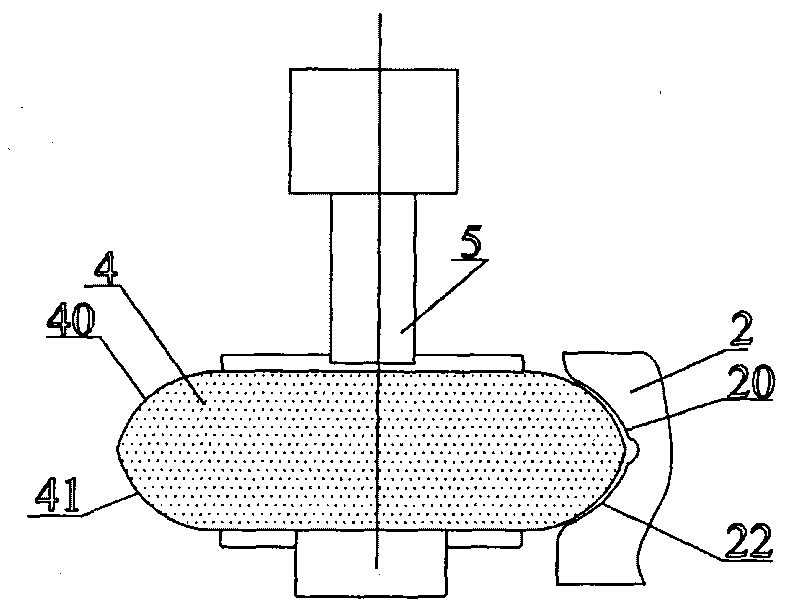

[0048] Such as figure 1Shown is a typical slewing bearing, mainly including outer ring 1, inner ring 2 and steel ball 3. Among them, the raceway of the outer ring 1 that provides the movement of the steel ball 3 includes the upper busbar 10 of the inner raceway, the oil groove A11, and the lower busbar 12 of the inner raceway, and the raceway of the inner ring 2 that provides the movement of the steel ball 3 includes the upper busbar of the outer raceway 20 and the oil groove B21, outer raceway lower bus bar 22. According to the basic concept of four-point contact, points A, B, C, and D are the circle centers of the inner raceway upper busbar 10, the inner raceway lower busbar 12, the outer raceway lower busbar 22 and the outer raceway upper busbar 20, while E and F , G, and H are the contact points between the steel ball busbar 30 and the upper busbar 10 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com