Free-etching oxidation manufacturing method of SOI submicron ridge optical waveguide back-taper coupler

A manufacturing method and optical waveguide technology, applied in the field of integrated optoelectronics, to achieve the effect of smooth side walls of the waveguide and low scattering loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] see Figure 1 to Figure 8 As shown, the present invention relates to a kind of SOI submicron ridge optical waveguide inverted cone coupler free from etching and oxidation manufacturing method, comprising the following steps:

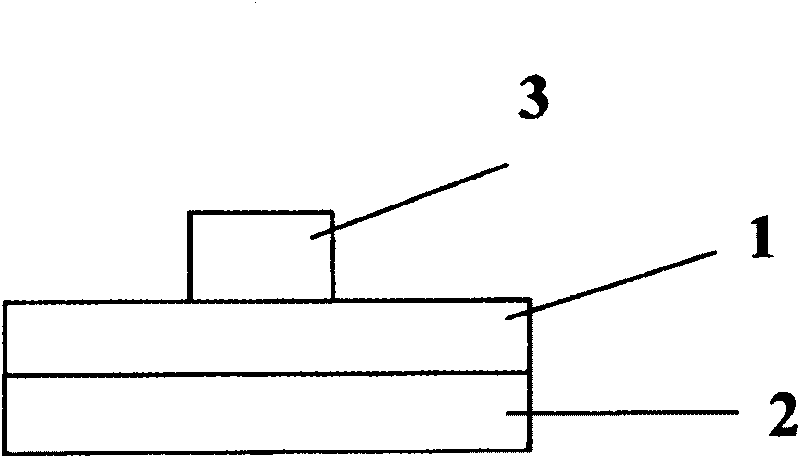

[0030] Step 1: Oxidize a layer of 500 nanometer silicon dioxide layer 1 on the top layer silicon 2 (thickness 340 nanometers) of SOI, this process actually consumes the top layer silicon 2 thickness of SOI is about 230 nanometers, and this oxide layer thickness can make The top layer silicon 2 of SOI under the silicon layer 1 can effectively resist the subsequent oxidation process.

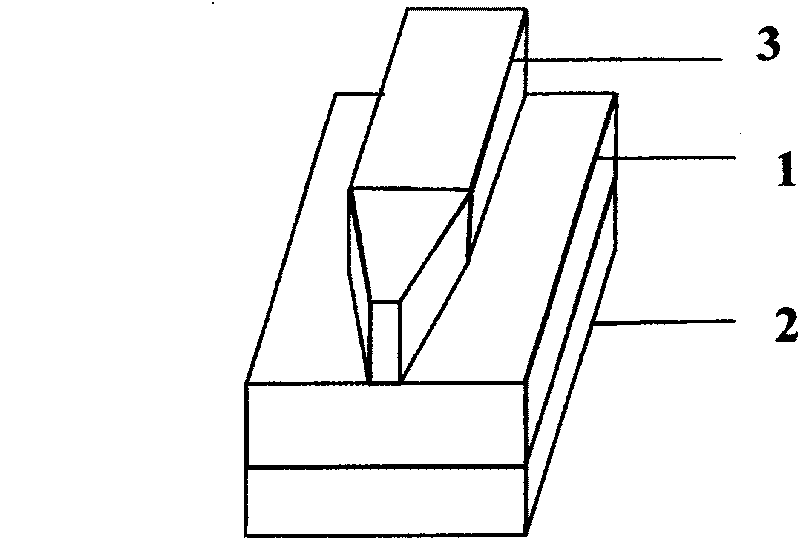

[0031] Step 2: Form a mask pattern 3 on the silicon dioxide layer 1 through a photolithography process. One end of the mask pattern is rectangular for subsequent formation of a ridge waveguide; the other end is tapered for subsequent formation of a ridge waveguide. type waveguide integrated strip waveguide inverted cone structure.

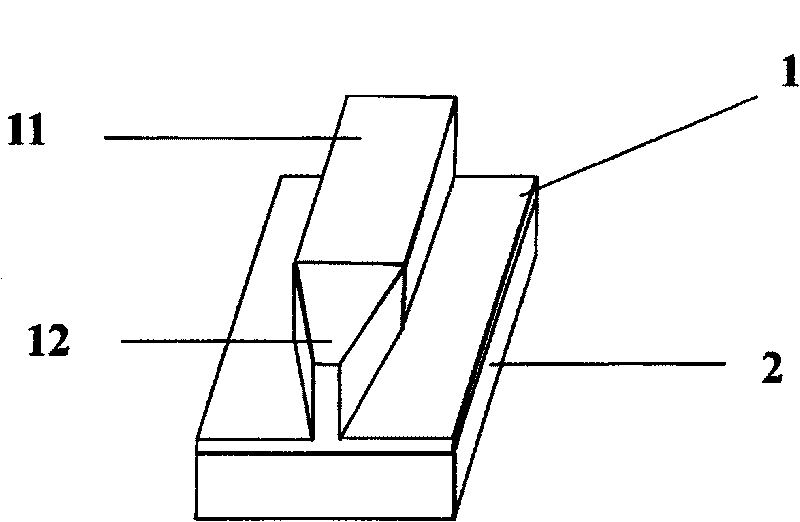

[0032] Step 3: Etch the silicon d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com