Binding agent for electrode of super capacitor

A supercapacitor and binder technology, applied in capacitor electrodes, capacitor parts, adhesives, etc., to achieve the effects of improving adhesion, flexibility, and compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] When performing homogenization of the supercapacitor electrode slurry, polyvinylidene fluoride of two different molecular weights is used as a binder, and N-methylpyrrolidone is used as a solvent. The ratio of activated carbon:conductive carbon:binder in the electrode slurry is 85%:7%:8%, and the solid content of the slurry is 30%. Among them, two kinds of polyvinylidene fluoride with a molecular weight of 350,000 and 700,000 are selected as the binder respectively, which are referred to as binders A and B respectively. Using mass ratios of 10:0, 7:3, 5:5, 3:7, 2:8, 1:9 and 0:10, the two binders were added to the solvent at the same time, stirred and dissolved for gel making, and then mixed with activated carbon, The conductive agent is mixed and homogenized and coated on the current collector to prepare electrode sheets. The bonding strength and maximum compaction density of the pole pieces obtained by testing the above ratios are shown in Table 1.

[0021] It can be...

Embodiment 2

[0025] When performing homogenization of the supercapacitor electrode slurry, two polyacrylic polymers with different molecular weights are used as binders, and water is used as a solvent. The ratio of activated carbon:conductive carbon:binder in the electrode slurry is 87%:8%:7%, and the solid content of the slurry is 26%. Among them, two kinds of polyacrylic acid polymers with molecular weights of 300,000 and 500,000 are selected as the binders, respectively referred to as binders C and D. Two polyacrylic polymer binders with different molecular weights The mass ratios used are 10:0, 7:3, 5:5, 3:7, 2:8, 1:9 and 0:10 respectively, and the two binders are added to the solvent at the same time and stirred to dissolve the glue and then mixed with the powder The materials are mixed and homogenized and coated on the current collector to prepare electrode sheets. The bonding strength and maximum compaction density of the pole pieces obtained by testing the above ratios are shown i...

Embodiment 3

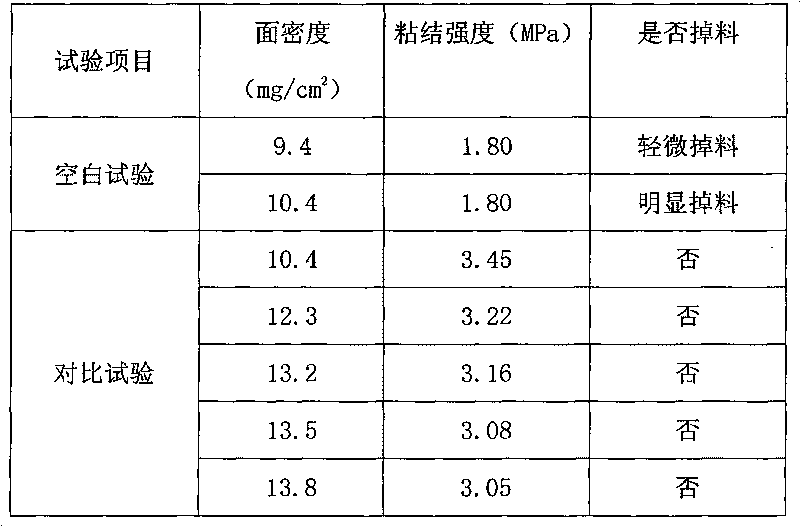

[0031] When performing homogenization of the supercapacitor electrode slurry, two polyethylene oxides with different molecular weights are used as binders, and water is used as a solvent. The ratio of activated carbon:conductive carbon:binder in the electrode slurry is 85%:7%:8%, and the solid content of the slurry is 22%. The experiment was divided into two groups. The blank experiment took 450,000 single-molecular weight polyethylene oxide, and the comparison test took two kinds of polyethylene oxide with molecular weights of 100,000 and 450,000 respectively and a mass ratio of 3:7. The total amount of binder used was equal. The binder is added into the solvent, stirred and dissolved to make a gel, mixed with powder materials such as electrode materials and conductive agents to make a homogeneous slurry, and coated on the current collector to prepare electrode sheets. The bonding strength and cycle performance of the pole pieces obtained by testing the above ratios are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com