Rubber additive and ethylene propylene diene monomer containing same

A technology of EPDM rubber and additives, which is applied in the field of rubber additives, can solve the problems of high price, large amount of addition, and increased cost of rubber sealing rings, and achieve the effects of good processing performance, low Mooney viscosity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

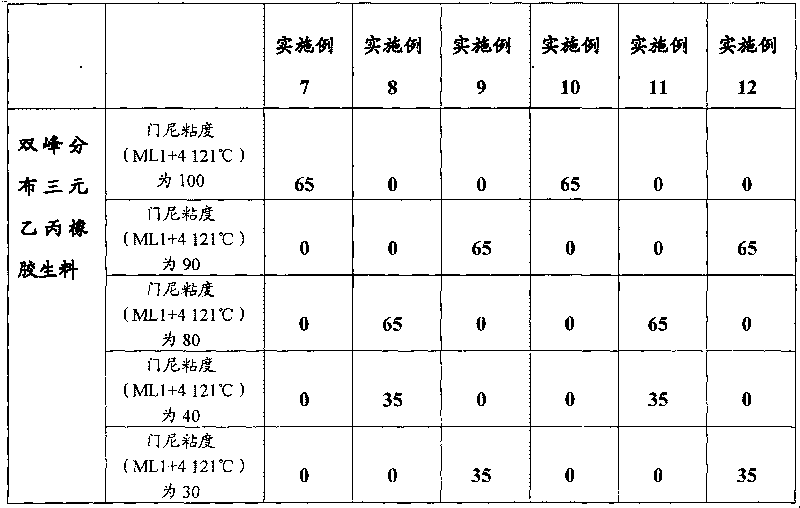

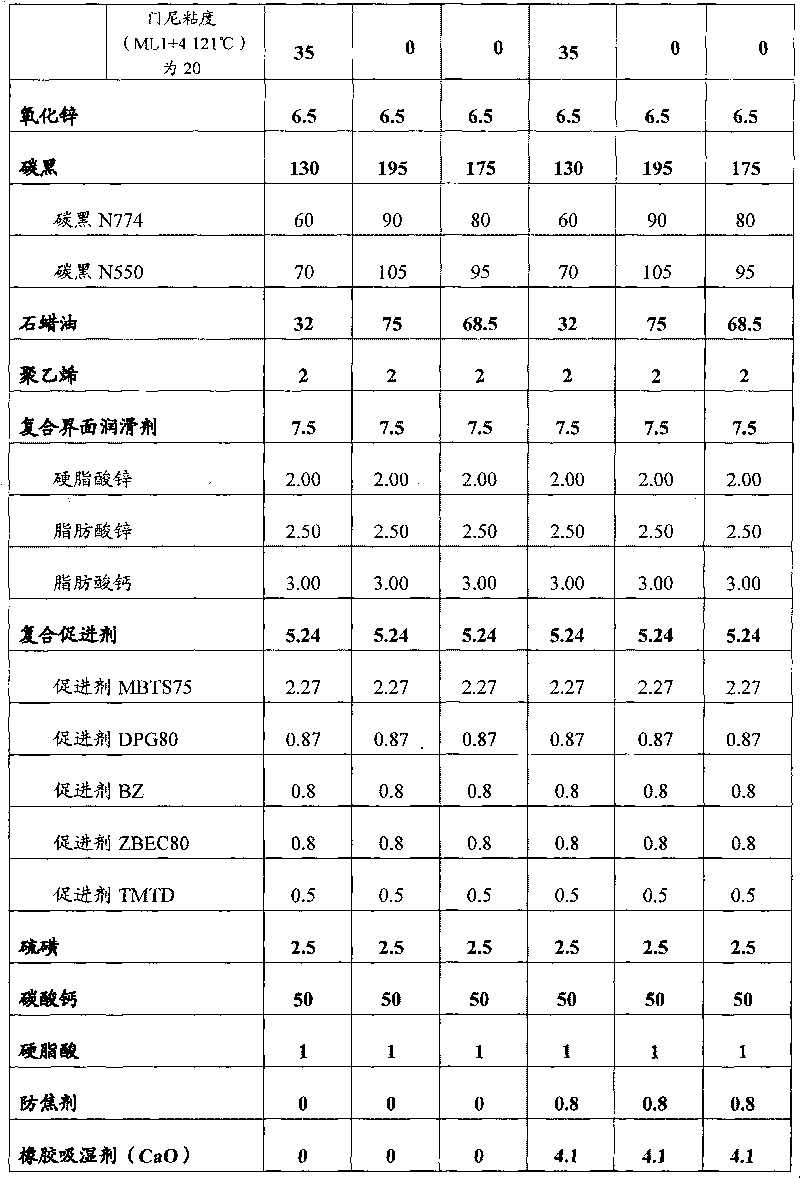

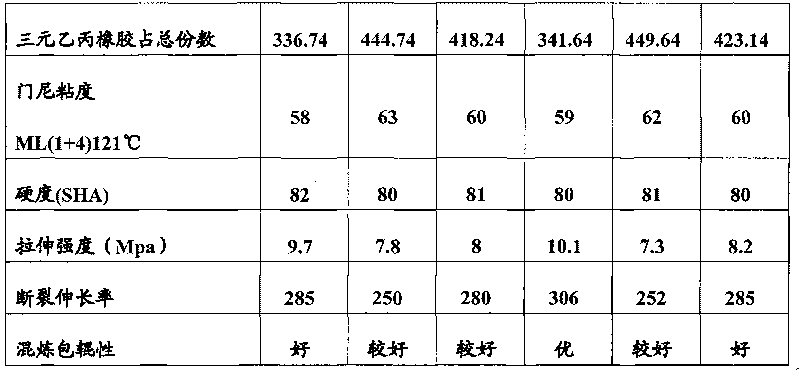

[0032] A rubber additive consisting of the following raw material components in parts by weight: 6.5 parts of zinc oxide, 2.5 parts of sulfur, 1 part of stearic acid, 2 parts of polyethylene with a melting point of 85 °C, 7.5 parts of composite interface lubricant, and 130 parts of carbon black Parts, 50 parts of calcium carbonate, 32 parts of paraffin oil, 5.24 parts of composite accelerator.

[0033] Wherein, the carbon black N774 is 60 parts, and the carbon black N550 is 70 parts; the composite interface lubricant is composed of 2 parts of zinc stearate, 2.5 parts of fatty acid zinc and 3 parts of fatty acid calcium; the composite accelerator is composed of 2.27 parts Part accelerator MBTS-75, 0.87 part accelerator DPG-80, 0.8 part accelerator BZ, 0.8 part accelerator ZBEC-80 and 0.5 part accelerator TMTD.

Embodiment 2

[0035] A rubber additive consisting of the following raw material components in parts by weight: 6.5 parts of zinc oxide, 2.5 parts of sulfur, 1 part of stearic acid, 2 parts of polyethylene with a melting point of 100 °C, 7.5 parts of composite interface lubricant, and 195 parts of carbon black Parts, 50 parts of calcium carbonate, 75 parts of paraffin oil, 5.24 parts of composite accelerator.

[0036] Wherein, the carbon black N774 is 90 parts, and the carbon black N550 is 105 parts; the composite interface lubricant is composed of 2 parts of zinc stearate, 2.5 parts of fatty acid zinc and 3 parts of fatty acid calcium; the composite accelerator is composed of 2.27 parts Part accelerator MBTS-75, 0.87 part accelerator DPG-80, 0.8 part accelerator BZ, 0.8 part accelerator ZBEC-80 and 0.5 part accelerator TMTD.

Embodiment 3

[0038] A rubber additive consisting of the following raw material components in parts by weight: 6.5 parts of zinc oxide, 2.5 parts of sulfur, 1 part of stearic acid, 2 parts of polyethylene with a melting point of 90 °C, 7.5 parts of composite interface lubricant, and 175 parts of carbon black parts, 50 parts of calcium carbonate, 68.5 parts of paraffin oil, 5.24 parts of composite accelerator.

[0039] Wherein, the carbon black N774 is 80 parts, and the carbon black N550 is 95 parts; the composite interface lubricant is composed of 2 parts of zinc stearate, 2.5 parts of fatty acid zinc and 3 parts of fatty acid calcium; the composite accelerator is composed of 2.27 parts Part accelerator MBTS-75, 0.87 part accelerator DPG-80, 0.8 part accelerator BZ, 0.8 part accelerator ZBEC-80 and 0.5 part accelerator TMTD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com